When it comes to custom over-molded cable, more goes into them than what meets the eye. And while custom cable solutions are objectively much better than off-the-shelf solutions, various myths surround over-molded wires. If you want to learn more about our custom cable, welcome to visit our website.

Many teams also overlook the performance benefits that over-molding provides to cables because of these rumors. So here are some of the myths and misconceptions that most couples have regarding using custom over-molded cables.

An Over-molded fiber cable

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

1. Custom Over-molded Cables Take Too Long To Manufacture

Let’s start with the most common and pressing myth: custom over-molded cables take too long to manufacture. Of course, for most people that hear about this misconception, it does hold some merit. Since the wires will be custom made, surely that will take more time.

However, there is nothing further from the truth. Thanks to modern advancements in manufacturing, teams should not worry themselves, wondering if they will receive their assemblies on time. There are infrequent occasions that your shipment may delay, but those are few and far between. Thanks to innovative technologies like 3D printing, our team can rapidly manufacture prototypes with ease. It can significantly reduce the design time for the product, streamlining a process that usually takes weeks into days.

2. Custom Cables Are More Expensive

Another popular myth that a lot of teams believe. Yes, custom over-molded cables are expensive, but a price tag is not a very accurate representation of value in most cases. Over-molded lines provide a lot to your project and offer much more than off-the-shelf over-molded cable assemblies.

For one, cables that use cheaper materials in their builds require much more maintenance than custom cables, and this cost can add up in the long run, essentially costing your team more than a good-quality connector. Moreover, our engineers respect budget parameters and will not exceed the budget unless they have your permission to do so. Our engineers can also help you save money by giving you options like using a stock connector instead of building one from scratch.

3. Custom Cable Connectors Are Not a High Priority.

An Over-molded AC Cable

This particular myth is very dangerous, especially for your product. Throughout the production stage of development, every team has a list of priorities. Not only should a custom over-molded connector be on that list, but it should be one of the top five. The simple fact is that electrical malfunctions make for a considerable percentage of injuries in the workplace every year. The most common reason for this is low-quality material construction.

When working with electronics, your team cannot compromise on the quality of the cable. Using cheaper materials can lead to electrical failures and compliance issues, and such problems can significantly hinder your product’s progress, which slows down your development.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

4.Can Only Provide IP67 With Limited Materials

Most teams believe that Over-molded cables are only available in particular materials, especially when providing IP67 waterproofing. While having some ground to it, this myth is not valid for most manufacturers, especially us. Accurate, some manufacturers cannot offer IP67 with various materials, but this does not indicate other companies.

We have a lot of variety in resins, conductors, and cables if you want your product to have IP67 waterproofing. So before you select a manufacturer, you should ask if they provide ample options in terms of material.

5. Off the Shelf, Cables Have the Same Quality as Custom Cables.

A black over-molded plug in front of a white backdrop

This particular myth is entirely baseless. First of all, custom over-molded cable assembly comes in different materials than off-the-shelf cables. Custom over-molded cables will also feature custom connectors as well as consumer-specific wiring that makes it considerably effective.

Moreover, off-the-shelf cables have one major disadvantage over custom cables; they are not application-specific. You can think of off-the-shelf cables as a jack of all trades but master of none. However, being a master is very important in most applications, as the product’s viability depends on these cables. Custom cables, on the other hand, specifically cater to your product’s needs, which makes it a better option by default.

Because of spot supply, the choice is more focused on providing a pool rather than meeting consumer demand. It automatically makes them less reliable than custom wired cables.

6. Over-molded cables Are Not As Flexible As Others

On the contrary, off-the-shelf and field, installable products are not as flexible as custom over-molded cables. With custom cables, you can change everything as per your requirements, from the color and shape of the connector to the length and width of the conductor inside, and it provides you with greater flexibility than any other cable on the market.

Furthermore, most off-the-shelf options that you choose may not accommodate your particular product or may malfunction midway. It can prove to be a severe problem, as your product becomes a ticking time bomb for some electrical failure to occur. Put, over-molded cables are much more flexible than their counterparts.

7. Over-molded Cables do Not Provide in-depth Customization

Over-molded cables do provide plenty of in-depth customization, especially since we are working on it. As we discussed earlier, you have free reign over most of the customization options that we have available. You can change the conductor, the insulating material, waterproofing, as well as the size and shape of the connectors.

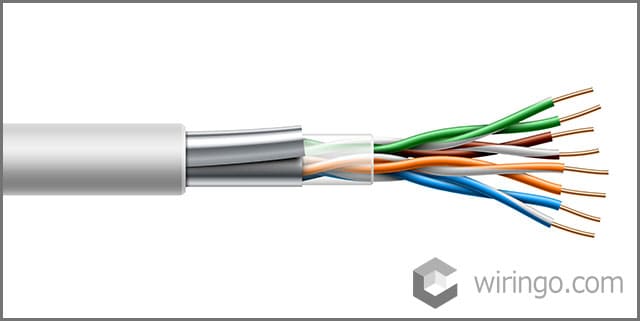

illustration of Twisted pair cable on a white background

Nothing is off-limits when creating your custom over-molded wires, and that is a level of customization that not many can provide. This myth can significantly hurt your product, as it may sway you from making the right choice in buying over-molded cables.

8. Custom Cables Have Much Larger Minimum Order Quantities

The myth in question has some grounds, as most manufacturers do have Minimum Order Quantities (MOQ). The reason for these quantities is simple; smaller orders require a lot more effort than they are worth. Since the design stage often takes the same amount of time, and if the order could be for only 50 or 60 cables, it is not worth their effort.

Lucky for you, we do not have excessive MOQ demands to meet, so we are pretty welcoming to teams that are not looking for a vast number of cables. Since we use an efficient process to develop our custom cables, the excess cost does not reflect you. clooms

Conclusion

Ensuring that you get just the right custom over-molded cables for your project should be one of your top priorities. And with the help of over-molded cable assemblies, you can focus more on your product and leave the wiring harness to us. Our over-molded cables provide a lot in customization and versatility, ensuring that the line we craft perfectly fits your product. So if you are looking for a quality custom over-molded cable, be sure to visit our website to learn more.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.