Every vehicle needs a wire harness, irrespective of its style, features, and parts. The wire harness helps connect all the components and power them, including power steering, in-dash displays, headlights, and heated seats. You must keep the wires in a harness away from high temperatures, projectiles, and harmful chemicals. Failure to do so will lead to wire breakage, brake failures, or other critical malfunctions. Thus, you must keep the wires covered and bundled.

You can protect the wires and cables of vehicle harnesses in many ways. Use zip ties as they easily bundle wires. Plastic conduits are also excellent for cable protection from rough surfaces, but they add weight and are not flexible. Another option is heat shrink tubing, which offers protection against chemicals, moisture, and heat but is time-consuming. How about picking cloth tapes for wire harnesses?

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Cloth tape for wire harnesses understanding

Cloth tapes are an excellent bundling option for the protective sealing and wrapping of cables and wires, and these are much more flexible and cheaper than other options. In cloth tapes, you can find various adhesives and backings with which you can offer sound dampening, electrical insulation, and abrasion protection. Also, these tapes are lighter and easier to apply than conduits and tubing.

zip ties

Application areas of cloth tapes

Although most automotive manufacturing uses automated techniques for bundling and wrapping wire harnesses, the manual application is still widespread. As wire harnesses have a complex design and critical functionality, you must be precise in tape application. Some areas of automobiles where manufacturers apply tapes manually include:

- Car’s interiors protect against environmental conditions and noises

- Engine compartment to protect against extreme temperatures, abrasion, and environmental stresses.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Types of adhesive

You can use several materials to make a tape like an adhesive on a backing surface. All these adhesives have different advantages and uses. For example, rubber adhesive provides resistance against abrasion and flexibility. Silicone and acrylic adhesives are suitable for high-temperature conditions up to 200 degrees Celsius, like in the engine compartment.

You must pick a suitable tape adhesive; otherwise, it may damage wires or their insulation. You can choose the adhesives based on the temperature resistance of the cables and their compatibility. Apart from these adhesive options, rubber and silicone tapes lack adhesives. Such tape sticks to itself only and creates a solid seal to prevent the flow of liquids.

Type of backing

Tape adhesive offers significant protection, but the backing also protects wires against unfavorable conditions and elements. Pick the backing based on the wire location in the vehicle and the elements to which the wires will be exposed. For example, glass cloth tapes are standard in the engine compartment as they resist heat, and some cloth tapes come with waterproof or flame-retardant coating.

The most common tape backing is PVC or polyvinyl chloride, as it solves various purposes. As it is flexible, you can tightly wrap the tape around wire bundles. For general bundling and positioning, you can use hand-tearable tapes. Some backings, when combined with acrylic adhesive, offer electric insulation. Apart from this, there are thick PVC tapes for fantastic abrasion resistance.

You can also use polyester for abrasion and heat resistance. Polyester is more flexible than glass and is also hand-tearable. Other than this, nonwoven polyester (PET felt/fleece) is standard in the vehicle body for sound attenuation.

The combination of different backings and tapes improves the protection level of the cloth tapes. You must remember the level of protection, wearability, and flexibility required in the application.

What factors make vehicle wire harness tape great for use?

What makes a great tape is the right combination of backing and adhesives according to the location and application in the vehicle.

A tight wrap

The most commonly used wire harness tape is PVC in the automobile industry. Due to its flexibility, you can do tight and firm fitting and wrapping of wire bundles, allowing them to easily pass through tight spaces among vehicle components.

Abrasion resistance

The abrasion resistance rating on cloth tapes starts from A and ends at F, where A means no abrasion resistance while F means very high abrasion resistance. The different classes are based on the international standard ISO 6722, wherein the scrap abrasion test; you rub an abrading tool back and forth across the cloth tape under specific pressure and temperature conditions. The tapes that survive less than a hundred strokes fall under the Class A category, while those that bear more than 15,000 strokes fall into the Class F category.

Insulation from heat and electricity

When it comes to heat and electric insulation, PVC is an excellent option. However, due to high engine temperatures, automobile manufacturers consider options like polyester, fleece, vinyl, and foil. For such high engine compartment temperatures, glass cloth tapes are the best as they offer protection from heat. Heat resistance and insulation are essential for tape backing; the adhesive layer must also withstand high temperatures. You should stick them into bundles without peeling off.

Resistance to chemicals and contaminants:

The wire bundles must show resistance against oils and contaminants, so woven tapes are a good option. However, for a very secure seal, you should opt for smooth polymers or foils. Further, PVC tapes are suitable for protecting wire bundles from corrosive substances. Sometimes, manufacturers coat the cloth tapes with flame retardant, chemical repellent, or waterproof materials according to the application requirement.

Tape wrapping wire and cable harnesses guide

Here are some steps for wrapping tapes around a vehicle’s wire and cable harnesses.

Choose tape types

Before you pick the tape, you need to ask several questions, such as

- What is the purpose of the tape?

- What type of tape is being used?

- What is the tape material; woven fabric, foil, or elastic polymer film?

- Do you need tape for loose holding or constricting wires into tiny bundles?

- Do you need any specific protection, such as improved dielectric insulation, EMI shielding, or thermal protection?

Based on this information, you can estimate how much coverage and layers of tape are required and how the installation should be done.

Decide tape quantity.

There is no set standard for calculating tape quantity. Some materials are thicker, while others are thin. Tapes with thermal and EMI protection need greater coverage.

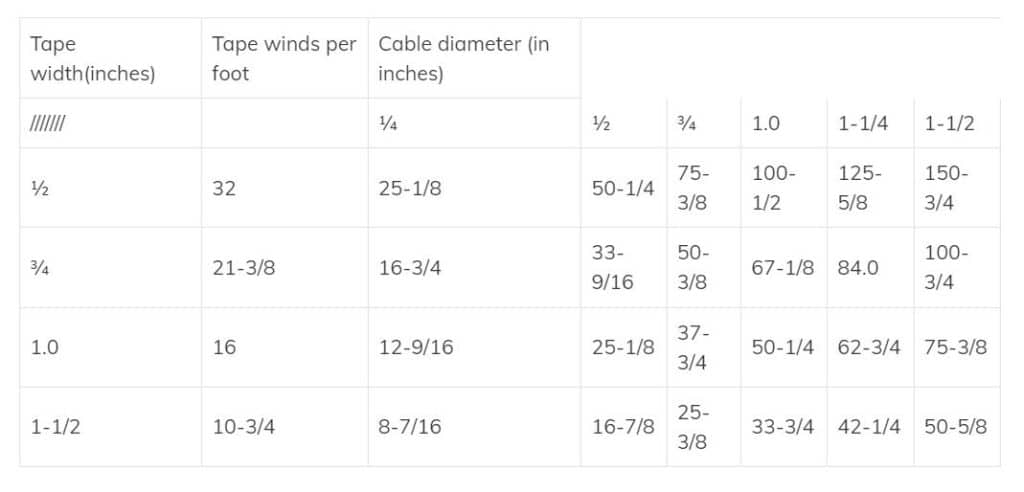

Here is a table that provides a rough estimation of the tape length needed for covering one foot of cable (in linear form). This information uses mathematical calculations based on 50% overlap, tape material with zero thickness, and a straight cable run.

If the tape has bends, you may need a higher quantity to cover one foot to maintain 50% coverage.

Precautions: do not use a wide tape to minimize the tape footage required, as it will result in wrinkles and large gap areas, thus failing to function correctly.

Caption: Tape length per linear foot of cable

Installation:

Before you grab a tape roll and begin installing it, you must know the different types. You can directly unroll the adhesive-backed tape keeping the adhesive side on the cable bundles. On the other hand, tapes with adhesive sides have a paper release liner; you must remove it before applying it to the cables.

While wounding the tape, start in a spiral manner making the first wrap at a 75-degree angle from the direction of the cable run. Now, while making the next wind, ensure that the second wind should overlap the first wind by about 50%. As the polymer tapes are elastic, you can create smooth and uniform wrapping with minimal wrinkles. Make sure you apply only a little force to these stretchable tapes as they turn thin in width, causing the coil to pull back and expose sticky adhesives.

Contrary to polymer tapes, woven or metal foil tapes have no elasticity, and thus you need to be more careful while setting the first angle with these tapes to ensure smooth winding of the tape.

If there are multiple breakouts, start backing up and wrap the tape over itself to make directional changes. You will find it much easier to wrap the tiny breakout legs first with a narrow-width tape almost equal to the diameter of the breakout leg. Once you cover all the breakout legs, use a wider tape to wrap the main cable. Also, using EMI tape, make 3 to 4 inches overlap on all tape intersections.

Finally, remember to use a fiberglass string or plastic cable tie to retain the tape ends, which may unravel if left untied.

Wiring harness repair tools

Conclusion

You may think that tape materials are versatile and inexpensive, but the final assembly cost is high as the process is quite labor-intensive. Further, you should understand that tape wrapping is like an art, and the final installation result may vary from person to person. Tape wrap jacket installations are highly costly and inefficient harnessing solutions. Ensure that you use tape wrapping on limited cable lengths only. For long-length cables, you should prefer zip-on jacket materials or wrap-around for complete jacketing.

For any help regarding tape wrapping, contact Wiringo. We are a leading manufacturer of the widest range of cable assemblies and wiring harnesses, which comes with utmost perfection and neatness.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.