Aircraft Wire Harness Manufacturer

As a leading aircraft wire harness manufacturer, Wiringo offers an extensive range of cable assembly options tailored specifically for the aerospace industry.

Our Clients

We stand out through our commitment to innovation and customization among leading aircraft wiring harness manufacturers.

Clients get high-quality custom airplane wiring harnesses designed to meet their specifications and enhance systems safety and performance.

Why Choose Wiringo?

Wiringo is the ideal choice for aerospace wire harness solutions, combining speed, reliability, and customization to meet the industry’s unique demands.

Fast Delivery

Timely delivery ensures your projects stay on track, with high-quality wire harnesses arriving when you need them most.

Reliable

Rigorous testing and quality control processes guarantee high performance, meeting the strict demands of the aerospace industry.

Diverse Selection

From standard harnesses to custom designs, we offer solutions for various aerospace applications or industrial equipment.

One-on-One Assistance

Our team provides personalized support, working closely with you to understand and fulfill your unique project requirements.

Manu facturing Capa bilities

Our product versatility and commitment to reliability and quality make us a trusted partner for OEMs seeking innovative and effective writing solutions.

Services

Our harnesses are constructed exclusively with Mil-Spec aviation components, including wire, pins, and connectors. All bundles are expertly tied, wrapped, or encased in expandable sleeving. We provide aircraft wiring harness fabrication for:

- Audio Panels Intercoms

- Autopilots

- EFIS

- LRU’s

- Radios

- Transponders

Process

Before engineering any wire harness, we conduct precise measurements to ensure the correct cutting, splitting, stripping, and marking of all wire and cable assemblies.

We adhere to IPC/WHMA-A-620 workmanship standards as required. Once the product is fully assembled, we apply any necessary labels and mark all clamp positions, ensuring precise placement within a tolerance of ±1/8″.

We conduct a series of in-process measurements and visual inspections to guarantee that the cable wire harness meets rigorous aircraft industry standards.

Customizations

We collaborate with you to create custom harnesses for specialized applications, such as:

- Onboard camera systems

- Avionics

- Communications

- Missile systems

- Plug-and-play installation

Pre-built Options

Applications include:

- Engine, Nacelle, Fuselage, Space, Landing Gear, Ground Support, UAV, and a host of System Wiring Harnesses

- Strain-Relief, Potted, or Closed Style Backshells (Custom or MIL Spec)

- Environmentally Engineered Designs

- Repairable Designs Lightweight, Durable Materials

- Multi-branched Closed Bundle and Open Bundle designs

- Ability to braid complex harnesses

- Cylindrical connector designs, as well as micro-miniature and D-sub

- Customized and Hybrid Designs

- Multicolor tracers available

- In-house Over-Braiding with Nomex®, Metal, Kevlar®, PEEK™, or other protective materials

Safety Testing

The Wiringo team will customize our thorough testing processes to meet the needs of your particular project and industry.

Certifications

We specialize in fabricating multi-branched electrical wiring harnesses with IATF 16949 and ISO 9001 certifications. Our production and inspection processes comply with IPC/WHMA-A-620 standards.

Samples and Prototyping

Tested cable assemblies are created to verify functionality and manufacturability, ensuring they perform as designed.

Flexible Order Quantities

Our advanced aircraft wire harness fabrication process handles small and large orders while maintaining top quality.

Harness and Cable Assembly Products

At Wiringo, nearly every feature of a wiring harness and cable assembly can be tailored to the application, so clients can choose elements that streamline airplanes.

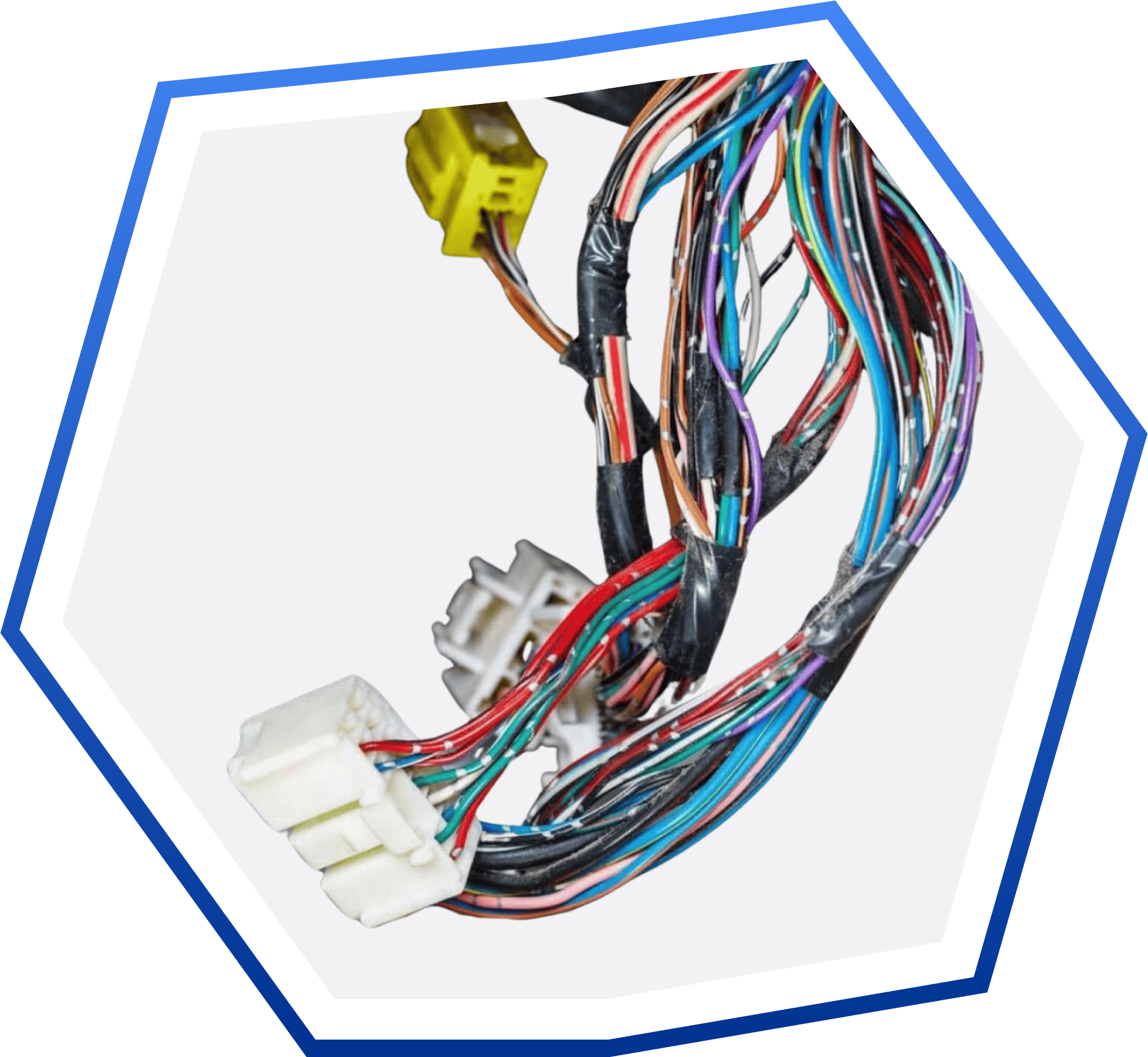

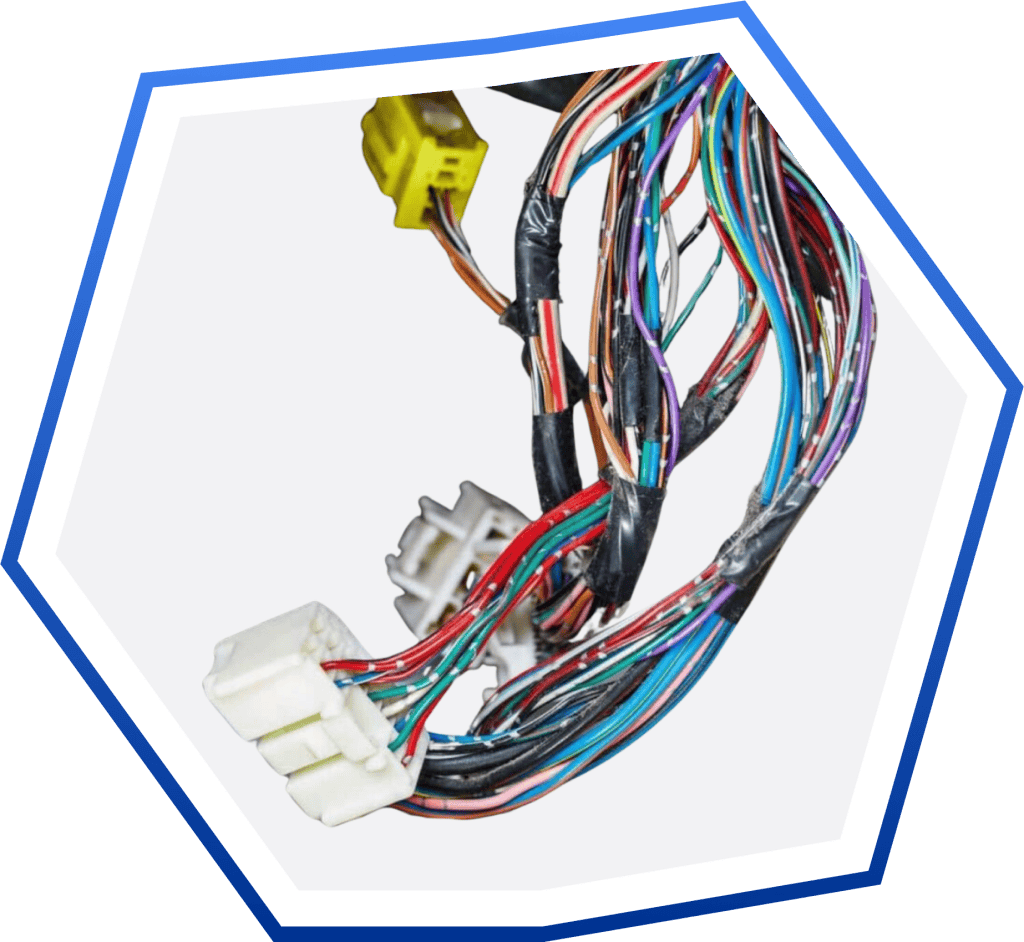

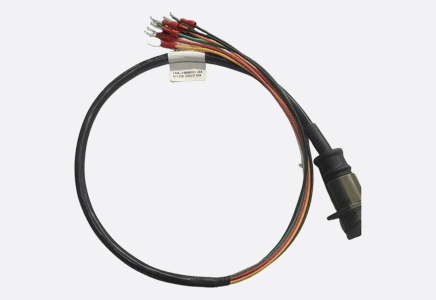

Closed Bundle Wiring Harnesses

These harnesses are engineered to efficiently organize and protect wires, minimize interference, and enhance durability in various applications.

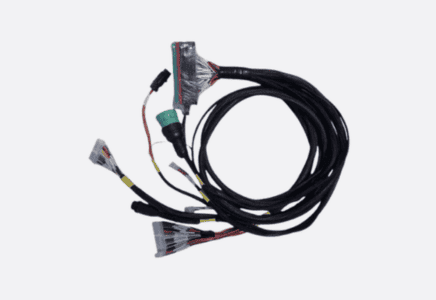

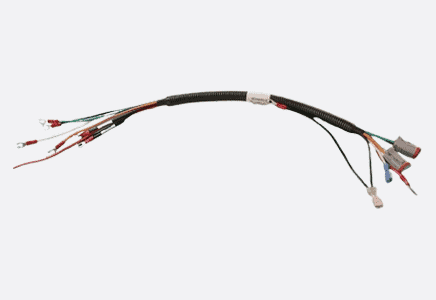

Open Bundle Harnesses

Open bundle harnesses are accessible, making them ideal when repairability is essential. This design is commonly used for signal and communication harnesses and is found on gas turbine engines, nacelles, and airframe fuselages.

Overmolded Wiring Harness

This type of harness features a protective oversold, providing added strain relief and environmental protection, ensuring reliable performance in challenging conditions.

Hybrid Harnesses

In addition to jacketed copper wire and cylindrical connectors, we can incorporate micro-miniature connectors, CAT 5 & 6 USB, D-sub, and impedance cables.

Aircraft Applications

Wiringo delivers tailored wire harness solutions for a wide variety of applications.

What Our Customers are Saying

See what thousands of happy customers have to say about Wiringo’s commitment to product quality and customer service

I have received an shipment of the cables that was supplied (p/o : 5130903714 )

I would like to say thanks you , to you and your staff ( factory ) well done.

I am very happy with the quality of the work, ( C )

Thank you very much for your hot support and efforts for our parts supply.

We received your DC cables with thanks a lot.

All parts passed inspection successfully!

Lead Engineer

I just received the cables. Once again, we are very pleased with the results. We are also looking forward to further cooperation in the future.

Please take care.

I could not ask for anything better in terms of quality since everything arrived in perfect condition.

Thank you very much and I look forward to future projects with Wiringo.

Thanks again for Wiringo's hard work in making this project a success.

Frequently Asked Questions

What is the typical lead time for custom wire harnesses?

Depending on design complexity, lead time is usually 4 to 6 weeks, with expedited options for urgent requests.

What materials do you use in your wire harnesses?

We use high-quality, durable materials selected for aerospace performance, including various MIL Spec aviation wires, cables, and connectors.

How do you ensure exceptional product quality?

We enforce strict quality control measures throughout manufacturing, including inspections and adherence to established standards.

Choose Wiringo’s Aircraft Wiring Harnesses

Partner with Wiringo for reliable, responsive service and exceptional performance in demanding environments. Request a quote today!