Battery cable Assembly Is used in a wide variety of applications to power your electrical systems. It would help if you used a battery cable to establish a connection between the battery and the vehicle’s electrical peripherals, RV, golf cart, or solar panel.

There are many types of battery cables available depending on the application, and sometimes you may be confused about the required battery cable. Do you distinguish the blown battery cable from the booster battery cable? Can you tell the difference between the ring terminal and the stud top?

You can find all the information about the battery cable and its applications in this helpful guide and determine which ones are right for you.

You can also contact our support team to customize your cable assembly. Let’s start reading right away.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

What is the Battery Cable Assembly?

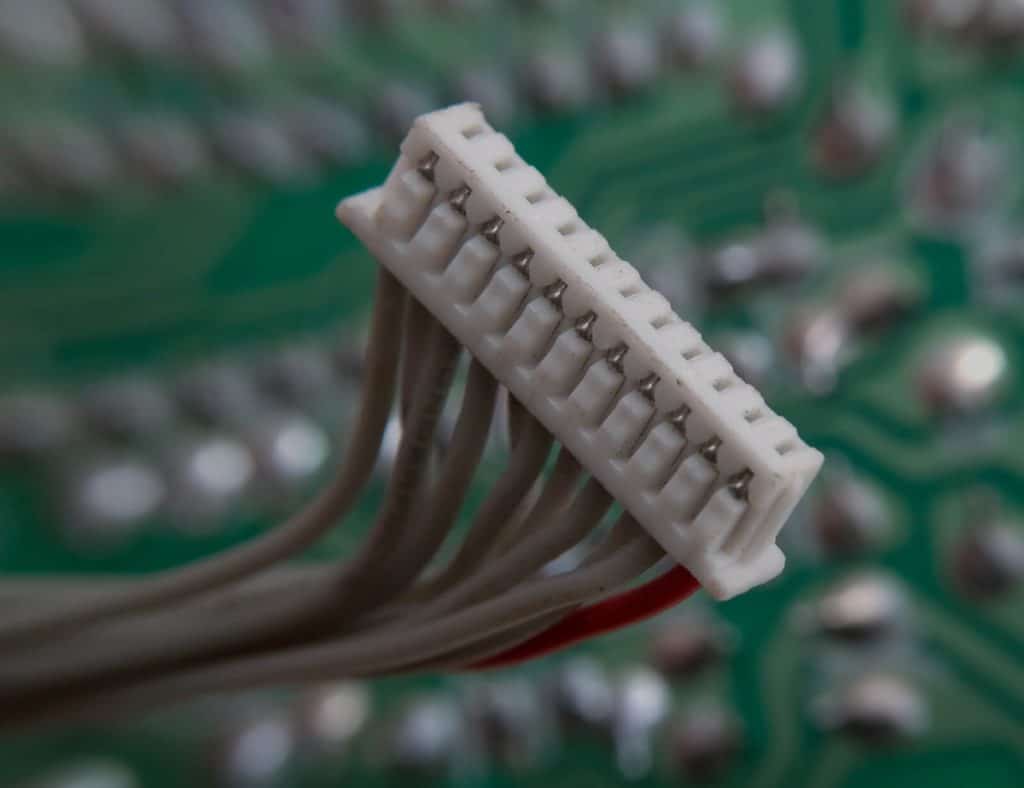

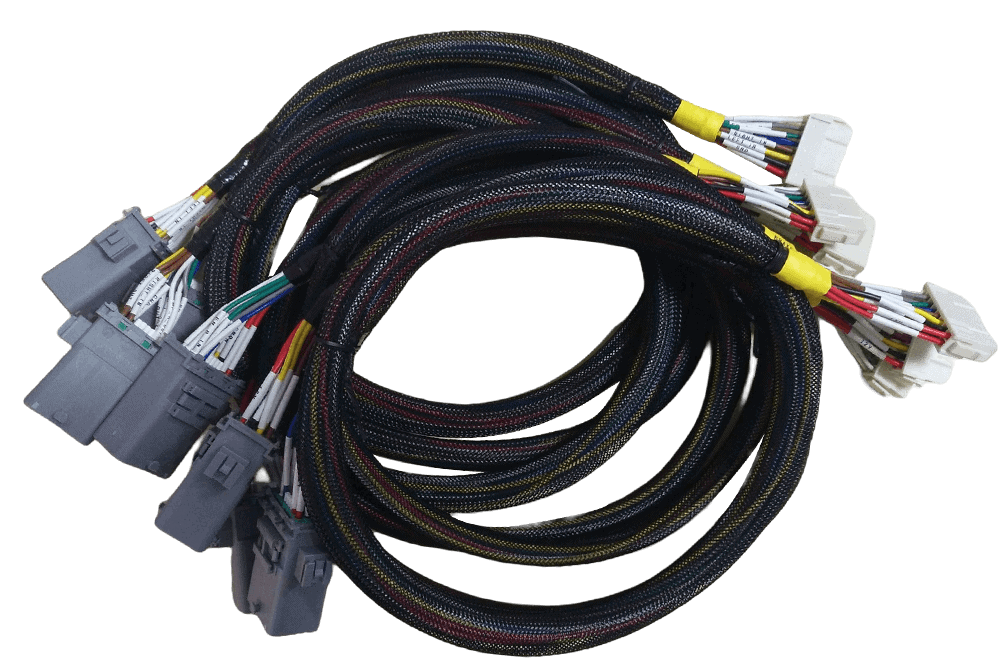

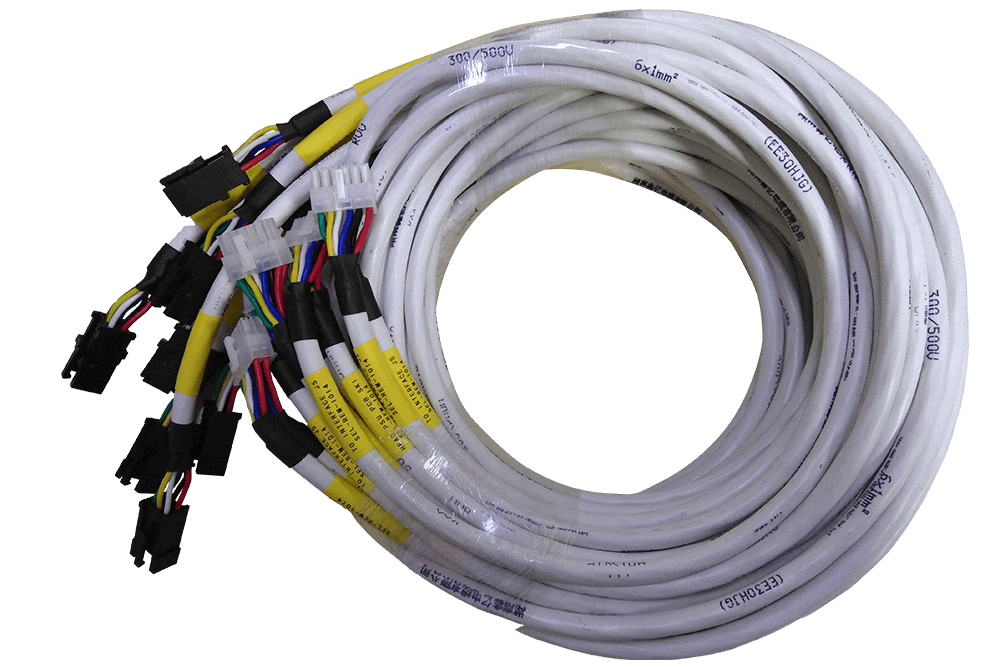

Battery cable assembly or harness is a set of cables of varying lengths. You can use the cables to hook up one or more batteries to the electrical system of cars, trucks, boats, solar power systems, and other equipment.

The battery cables come with terminated ends to easily connect with your battery. You can also choose from a wide range of terminals and boots based on your application to meet different jobs’ needs.

The battery cables are generally exposed to harsh conditions like vibration, heat, corrosion, or moisture as they run from the battery to different automobile parts. For this reason, they make use of good quality and thick wires which can withstand extreme conditions.

Battery cables are built according to specifications dictated by OEMs and manufacturers. But you can also order custom battery cables of varying size, length, types, terminals, and color.

Unlike other cables

Battery cables are meant for use only with batteries and electrical systems. They are not general-purpose wires that you can use to connect a device to the power source.

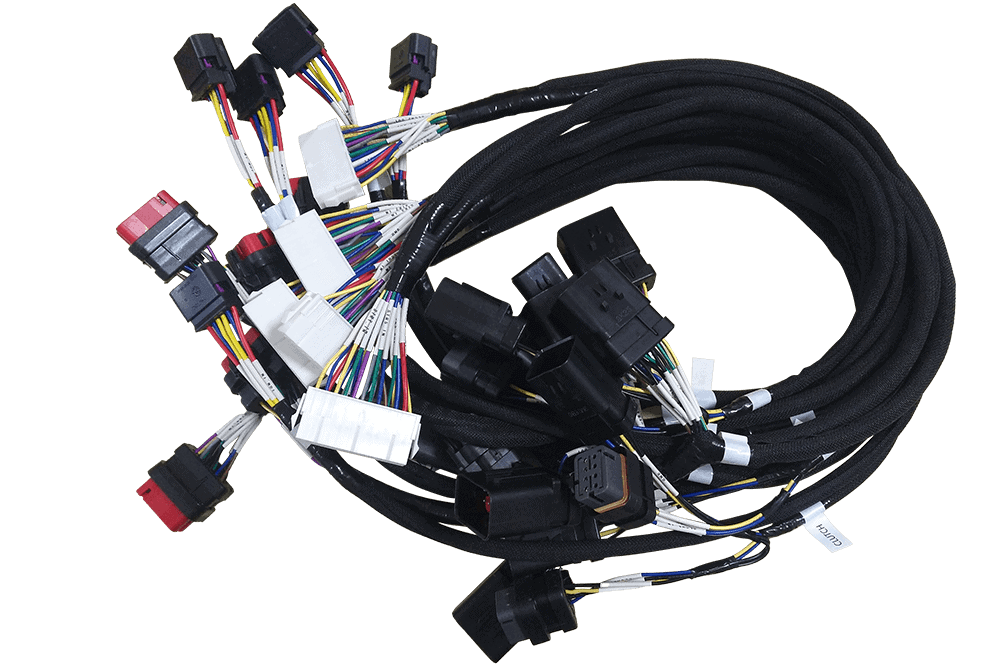

Battery cables often come in the form of harnesses and provide many advantages over loose cords and wires. They are bounded into a harness so that even you can save space and make them withstand adverse conditions like corrosion and vibration. If they came in the form of loose wires, you would need to extend them all over your automobile.

Battery cables are designed to last for a long time and reduce the risk of shorts. You can also expect a standard installation process as the terminals can easily connect to the battery and the electrical system without any confusion.

Without battery cables, all our vehicles, boats, and equipment would sit idle. You will need battery cables to provide power to the electrical system and make them functional.

Now that you know what a battery cable is let us discuss the different types of battery cables.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Chapter 2 – Types of Battery Cable Assemblies

Battery cables can be of different types, and you must know their specific uses. This section will find out the difference between battery leads, automotive primary leads, welding leads, and marine duty wires.

Tapered Post Battery Cable Assembly

The company offers tapered post battery terminals in stamped brass, lead, and forged bronze, granting all the pros each material has. Cable assemblies come in many cable configurations, including lengths, different plating options, and even with or without double-headed nuts.

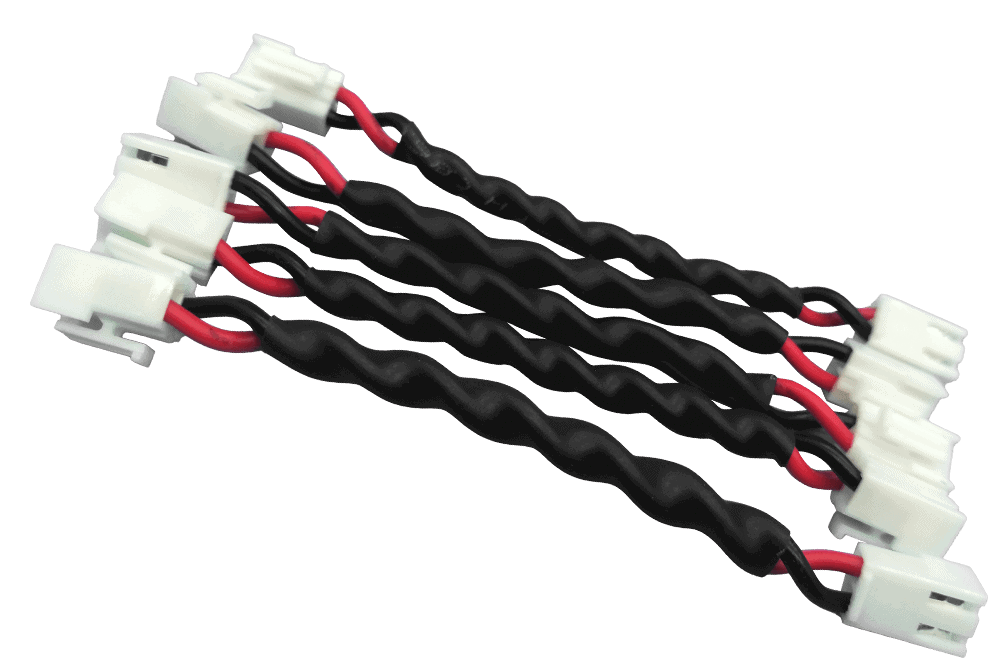

Ring to Ring Battery Cable Assembly

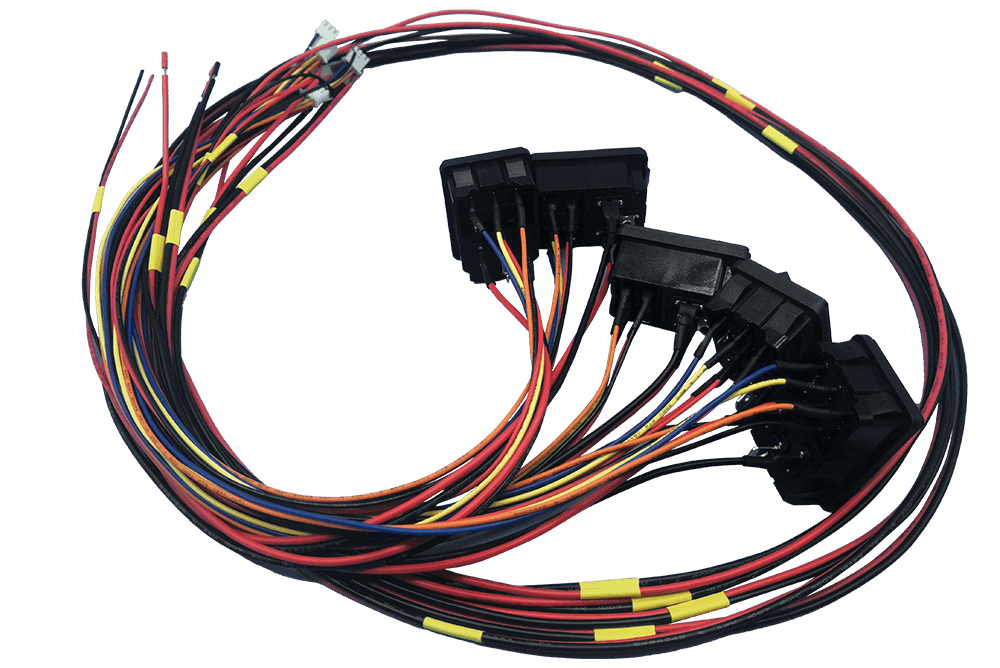

Many ring-to-ring plating combinations are available to fit your needs, including brass and copper options with both open or closed barrel terminals. These cable assemblies have the capability to crimp various wires at a time in one single terminal. Also, they are corrosion-resistant and endure pulling.

Flat/Ground Strap Battery Cable Assembly

Wires come in flat and round presentations and terminals made of stamped thimble, lead cast, open barrel, and lug are also available.

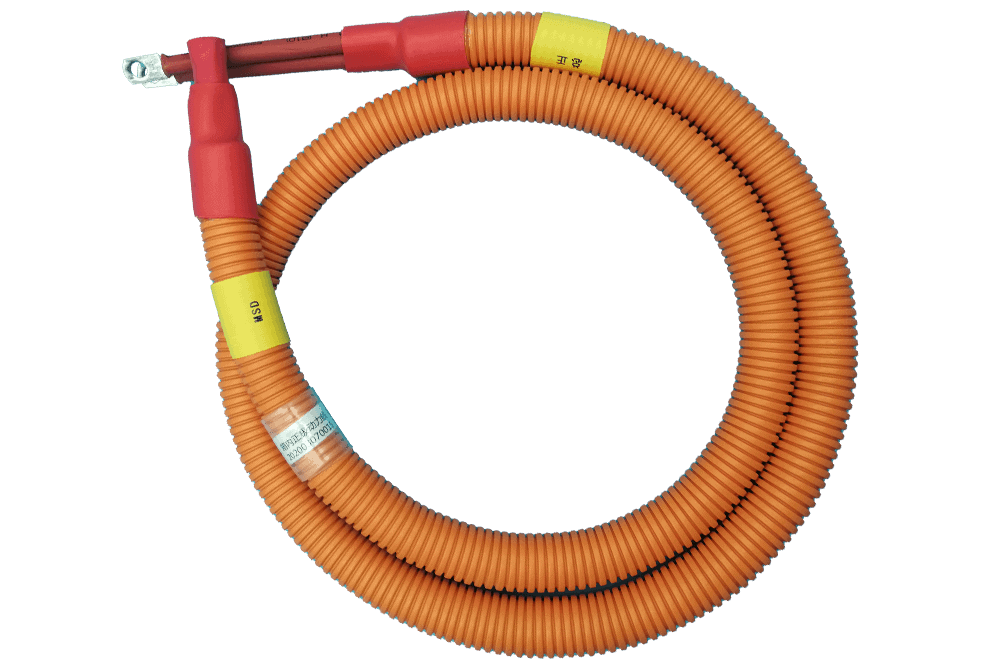

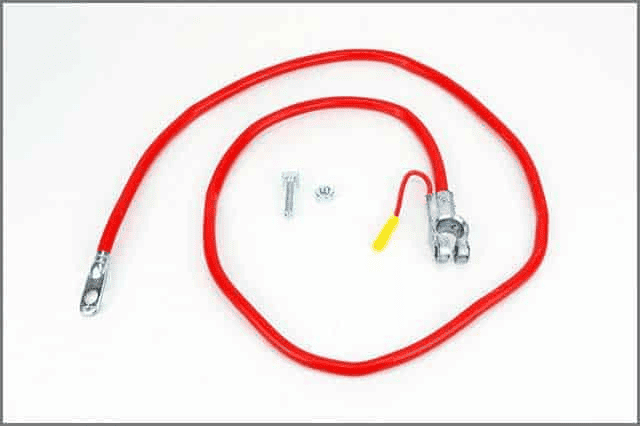

Booster Battery Cable Assembly

These booster battery cables are perfect to transfer electrical power from the battery to a vehicle without requiring a big space. Cables come in many presentations and offer molded and printed stripe markings to help conductors differentiate the wires.

Fused Battery Cable Assembly

It’s possible to customize the fuses to fit your power supply needs at all times. Also, they endure temperatures of up to 125ºC.

Battery Cable Assembly Applications

Battery wires have a wide-ranging application in different industries and equipment like cars, boats, battery banks, and golf carts.

Automobiles

Battery cables are most commonly found in automobiles and transfer electric current from the battery to the vehicle’s electrical parts. You will generally find two cables- the positive cable, which connects to the starter, and the ground cable, which connects to the engine block or the chassis.

Most of your automobile’s electrical components will be ground to the chassis or engine block. Battery cables enable you to start your engine and provide power to different electrical parts.

One of the main advantages of battery cables is that it is used to power the electrical of your automobile. You will not be able to operate your automobile without a proper battery cable assembly.

A disadvantage of automobile battery cable is that you cannot use it for other purposes. You may also need to replace them after some years as they withstand harsh conditions, vibrations, and abrasion daily.

Gauge Golf Cart

Golf Carts form a unique application of battery cables. You will need a battery wire for your golf cart to connect the electrical parts if you have installed extra batteries. People who modify their golf carts with larger motors will also require battery wires.

You can customize the terminals to match the needs of your final application.

Solar Battery Banks & RVs

Solar panels are connected to sets of batteries to store the power generated from the sunlight. You will have to use a battery cable to connect the solar panels to the battery banks for transferring the power.

If you drive an RV, you may also require battery cables to connect extra batteries to various electrical peripherals like lights, TV, and other gadgets.

Battery Cable Terminal Corrosion

Car battery terminal corrosion is, unfortunately, unavoidable. This chemical reaction is bound to happen sooner than later. When it happens, it leaves a white or blue-is powdery residue that covers both the bolt and the terminal that reduces the current conductivity to the machine.

Types of Battery Cable Terminal Corrosion

Battery terminal corrosion starts in the inside of the car battery when the chemicals start to interact with the gasses said chemicals emit. However, battery terminal corrosion means different things depending on which terminal is present.

Negative Terminal

When the negative terminal corrodes, means that the car battery is not charging properly or is undercharged. This usually happens if the car stops or its owner doesn’t drive it regularly anymore, leading to lead sulfation.

Positive Terminal

On the other hand, when the positive terminal corrodes, it means the car battery is overcharged. This happens after repetitive use of the car for long, consecutive hours leading to copper sulfation.

Reasons for Battery Cable Terminal Corrosion

There are a few variables to consider as reasons for corrosion on the battery terminal. These will be vital in the hopes to avoid it from happening so soon.

Aging Battery

This applies to any machine or device running on batteries whether it’s a car, truck, or even cellphone. After 4+ years of consecutive and extended use, the battery will corrode and show poor performance. If you experience this, it’s time to go for a new battery before it’s too late.

Charge Disbalancing

As you saw earlier, charge disbalance happens on any or both battery bolts. However, it all starts on the inside of the battery. Car batteries charge and discharge depending on the use of the car. If users don’t drive the vehicle properly, it will lead to the battery charging poorly, and finally, to corrosion.

Electrolyte Spillage

Car batteries hold water or Sulfuric Acid on the inside to speed up the chemical reaction needed to make it work. However, if the liquid filters out of the battery, it will lead to corrosion and poor battery performance on lead-acid batteries.

Hydrogen Discharge

This is one of the car battery terminal corrosion’s most common reasons, especially on batteries that use Sulfuric Acid instead of water as the electrolyte. It happens due to the interaction between the hydrogen discharged and the battery terminals while being under the cap.

Problems of Battery Cable Terminal Corrosion

As a result, it will come in handy when experiencing the poor performance of the vehicle.

Failing Electronics

All electronics inside the vehicle depend on the car battery, and when this is faulty, all electronics will start to fail as well. This includes the sound system, air conditioner, automatic windows, and even automatic car doors.

Engine Starting Troubles

It’s possible to damage your engine starter and experience malfunction due to low voltage. This translates into a mandatory check-up or even engine starter replacement.

Malfunctioning Transmission

Cars commonly use a computer system that depends on the battery to fully manage the car’s transmission. When the battery sends a low current to the system, it fails and leads to missing gearshifts and ultimately, accidents on the road.

How To Fix Battery Cable Corrosion

Chemistry plays a big role in fixing car battery corrosion and it’s easier than you think. In any of the following solutions, it’s important to have the engine off and know there’s no issue on which battery terminal to disconnect first.

Baking Soda Solution

For mild battery terminal corrosion, using a baking soda solution is a great battery terminal cleaner. Mix enough baking soda or Sodium Bicarbonate with water to make a slush-like consistency mixture. Then pour it over the terminals and scrape it around with a brush until the corroded battery terminal is clean. Finally, clean the terminals with water and a cloth.

Soda Water

On another hand, if you look for a corrosion quick fix, using soda water is the solution. If you’re on the road and experience car battery issues, pouring soda water or any soft drink on the terminals for a while can help you. Let it rest for a few minutes, clean with a towel or sponge, and that’s it.

Baking Soda Immersion

Finally, for extreme battery corrosion, immersing the terminals in a baking soda for about 20 to 30 minutes will cause the corrosion to fade. If after this the corrosion is still present, change the clamps completely as shown in the next video.

Conclusion

We can help you zero in on the right type of battery cable to use in your car or solar panels. You can also place custom orders and specify the length, width, diameter, colors, terminators, and other specifications. Cloom Tech provides tailor-made services to match your quality demands- contact us today to find out more!

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.