If you’re in the market for a black PCB, you may be wondering what all the fuss is about. After all, any old PCB will do, right? Wrong! Black pcb are becoming increasingly popular due to their many benefits. In this blog post, we’ll discuss everything you need to know about black PCBs so that you can make an informed decision before purchasing one.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Types of PCB Colors

Below are some of the various types of PCB colors.

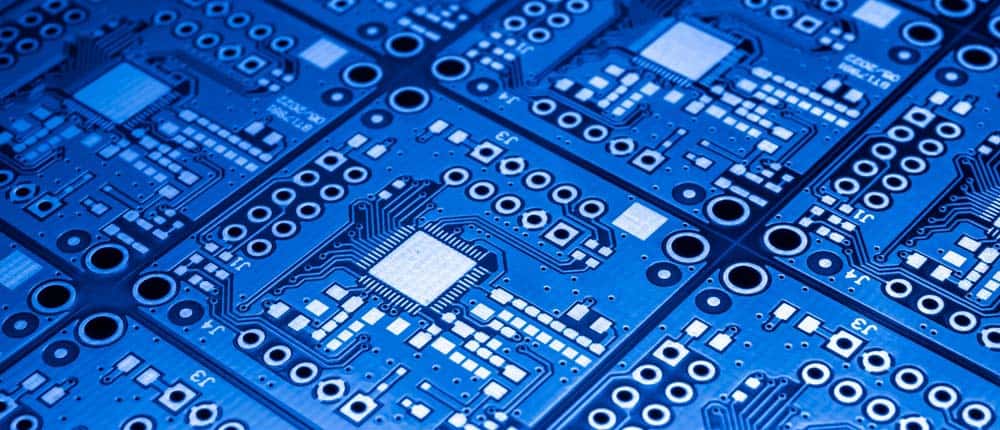

Blue PCB

Often, blue PCBs are referred to as blue boards made of a copper-clad core, which is a similar layer of copper.

Ideally, blue PCBs are perfect for applications that require higher strength, like controlling heavy machinery, since they have a denser and thicker layer of copper.

Also, blue PCBs operate at a higher voltage, facilitating the flow of high current through them.

Caption: Blue PCB

Furthermore, you can get blue PCBs with various coatings, such as a conformal coating or tin finish.

Such coatings offer different properties, therefore making them ideal for specific applications.

These are normally light blue; however, they’re available in various other colors. You can get them in different thickness levels ranging from 1/4” – 1/16”.

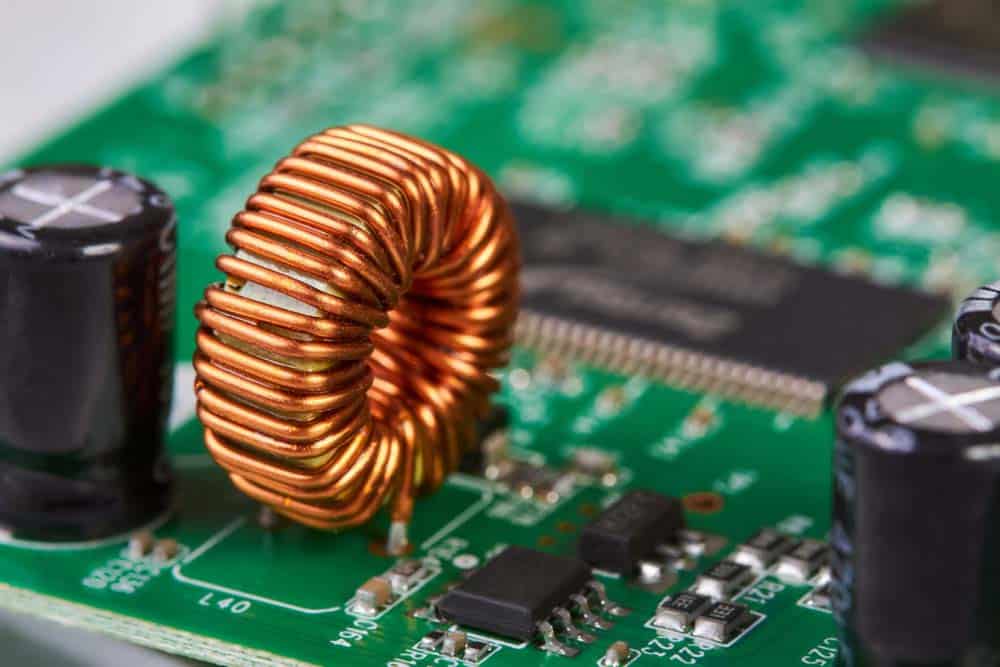

Green PCB

Green PCBs, often referred to as green boards, are ideal for low-power applications such as simple electronics.

Also, they’re easier to manufacture at a low cost since only one side of the PCB is coated with copper.

Furthermore, such boards are rather slim ranging from about 0.062” – 0.031”.

Caption: Green PCB

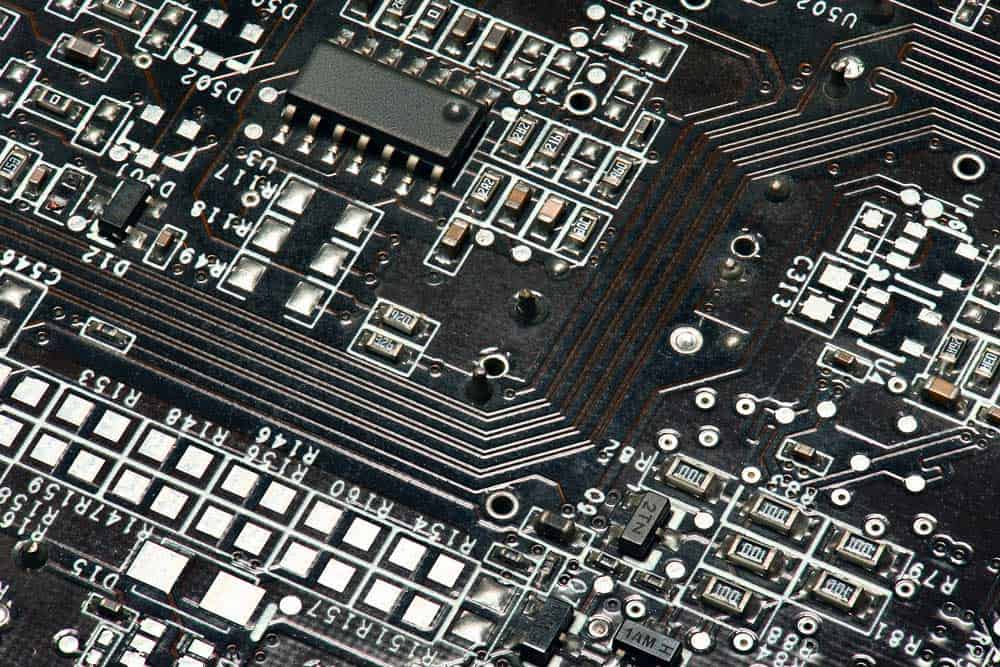

Black PCB

Black PCBs are made with a higher percentage of copper, making them ideal for applications requiring high amounts of current, like electric heaters, distributing power within the electronic product.

Also, black PCBs offer higher resistance and are, therefore, less efficient compared to standard PCB boards.

However, black PCBs offer better voltage regulation, making them ideal for high-frequency applications, such as SWPS, power supply rectifiers, and high-voltage applications.

Caption: Black PCB

Red PCB

You can use red PCBs for several reasons, such as to mount and secure components or make electrical connections.

Red is a popular PCB color choice since it’s easily visible and distinguishable from other colors.

If you choose a red PCB, it’s important to consider the number of layers and the board’s shape, thickness, and size.

What is Black PCB?

SMD LEDs on PCB

Black PCB is a special type of printed circuit board that is black. The black color is achieved by adding a black solder mask to the PCB.

The black solder mask is a thin layer of polymer that manufacturers apply to the PCB during manufacturing.

Solder Mask for black printed circuit board

The black solder mask is what gives black PCBs their unique look. The black mask helps to hide imperfections in the PCB and makes the PCB look more professional.

In addition to the black color, the black circuit board has a glossy finish.

This glossy finish is achieved by adding a black solder resistor to the PCB. The black solder resist helps to protect the black solder mask from damage and also provides a nice finishing touch.

Black solder masks are becoming more popular for a variety of reasons. One reason is that the black circuit board tends to be less expensive than other colors of PCBs.

Another reason is that black PCBs are more durable and tend to last longer than other colors of PCBs. Finally, they tend to have a more professional appearance than other colors of PCBs.

Matte Black PCB:

Matte black pcb is a black circuit board with a matte finish. And matte black circuits are becoming more popular for a variety of reasons.

One reason is that matte pcb boards are less expensive than other colors of PCBs.

Another reason is that matte black PCBs are more durable and tend to last longer than other colors of PCBs.

Finally, they tend to have a more professional appearance than other colors of PCBs.

Is Black PCB Board More High-End?

It’s unclear when most people deemed black PCB to represent high-end products.

However, you can note that most major manufacturers, such as MSI, Asus, and Apple, use black PCBs for motherboard designs.

Some manufacturers even go as far as using black as a premium parameter.

Black PCB Advantages

High-tech electronic PCB with processor and microchips

As we mentioned, black PCBs have several advantages over other colors. The following are some of the advantages:

Versatile:

You can use black pcb for various applications, making it a versatile option for businesses and individuals.

In addition, they are also less likely to show fingerprints and smudges, making them ideal for applications where a clean look is important.

Light Reflection

Black pcb are less likely to reflect light than other colors of PCBs. This is important for applications where a high degree of light reflection is undesirable.

Heat Dissipation

Black pcb is also a good choice for applications where heat dissipation is important. The black color of the PCB helps to heat absorption, dissipating it more effectively than other colors of PCBs.

Visually Appealing

Circuit Board

Furthermore, it can be a visually appealing option for applications where aesthetics are important. The black inks of the PCB can give your project a sleek and professional look.

Anti – Plagiarism

Black is also the best color for PCBs in environments where anti-plagiarism is important. The PCB’s black color helps make it more difficult to copy, making it more secure.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Disadvantages of Black PCB

The main difference between black PCBs and other PCBs like blue, yellow, and red PCBs is the use of a different color solder resist paint.

If both the design and manufacturing process for all PCBs are the same, then the color shouldn’t significantly impact the performance.

Like most things, black PCBs aren’t perfect and pose several disadvantages, such as the following.

- Any slight scratches or stains are easily noticeable on black PCBs. During transporting and storage, any mishandling could make the product appear unappealing. Further, you’ll find that trying to get rid of stains on a black PCB could worsen things.

- They offer a low surface resolution. With insufficient light sources, it’s difficult to tell apart the routes on the black PCB surface, making it difficult for DIY makers and factory visual inspection.

- Black ink is a bit more toxic despite costing more than green ink, making wastewater management more difficult for PCB manufacturers.

Some Misconceptions About Black PCB

black PCB misconceptions

There are a few misconceptions about the black PCB that we need to address.

The first is that they are more expensive than other colors. This is simply not true. PCBs in black pcb coating are no more expensive than any other colored PCBs.

The second misconception is that they are only for high-end applications. This is also not true. You can use black printed circuit boards for any application, from high-end to low-end.

So, if you are looking for black-printed circuit boards, don’t let the misconceptions stop you.

Why is a green solder mask the most popular option for PCB manufacturers?

Green PCB close-up shot with several electronic components

Green is the industry standard for PCBs. Plus, it has been that way for many years and is not likely to change anytime soon.

Besides, the green color is easy to see and makes it easy to find defects.

Also, green is the easiest color to match when repairing a PCB.

If you are looking for black pcb boards, don’t be discouraged by the industry’s preference for green solder masks.

You can still find plenty of black pcb boards out there. Just know that black is not the norm and may be harder to find.

Best Design Tools and CAD Software

Engineer Working with CAD Software on Desktop Computer

Now that you know all about the black PCB board, it’s time to start designing your own!

There are a few things to keep in mind when designing black circuit boards:

- Use black Solder Masks. This will help to prevent light from reflecting off of the board and making it difficult to see.

- Use black silkscreening for any text or markings on the board. This will help the text to stand out against the black background.

- Use a black or dark-colored PCB finish. This will help to protect the board from scratches and other damage.

There are a few different CAD software programs that you can use to design your black PCB.

- Autodesk EAGLE is a popular choice for PCB design. It has a free version that you can use to get started.

- KiCAD is another popular choice for PCB design. It is an open-source program that is available for free.

- OrCAD is a commercial PCB design software that you can purchase.

Once you have designed your black PCB, you will need to send the design files to a fabrication company. There are many different companies that offer black PCB fabrication services. Our company is able to offer quick turnaround times and have a minimum order quantity of just one board.

When you are ready to purchase your black circuit boards, be sure to use our quote form. This will ensure that you get the best price and delivery time for your project.

Black PCB Applications

Black circuits are common in many areas. The following are some of the more popular applications:

-Automotive

Car stereos

This includes black printed circuit boards for use in vehicles, such as for car stereos, navigation systems, and alarm systems.

Besides, they are also applicable in immobilizers, keyless entry, and door lock systems.

-Industrial

The operator programs the CNC manufacturing machine

Black printed circuit boards are applicable in many types of industrial applications. Such as black PCBs for control panels, machine control, process control, temperature sensor, and data acquisition systems.

-Consumer Electronics

Digital cameras and the city night

Black circuits are common in a variety of consumer electronics. such as digital cameras, camcorders, and notebook computers. Also for cell phones, PDAs, and MP players.

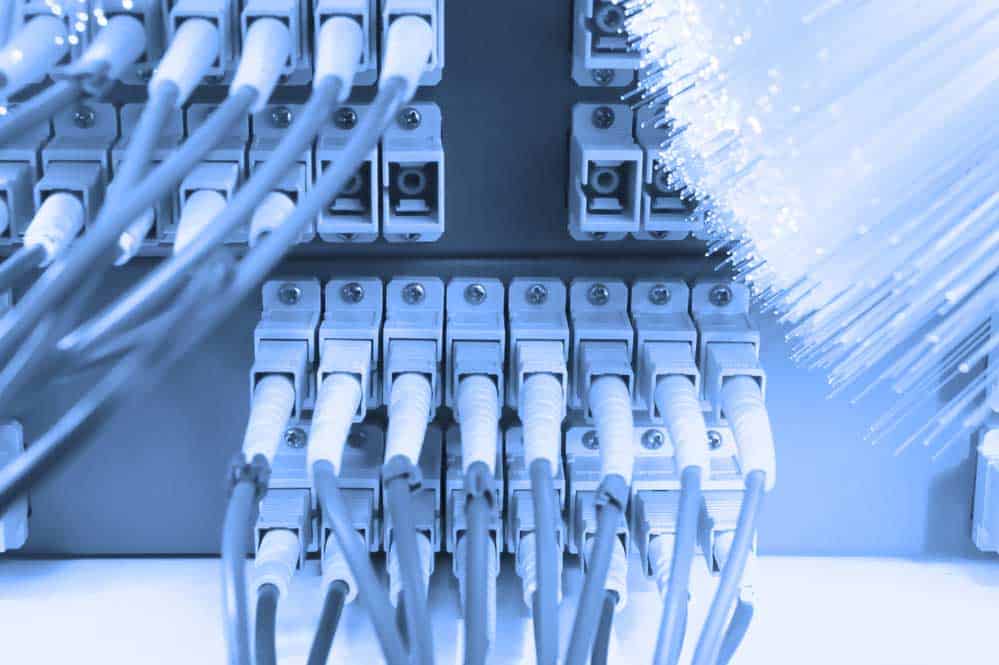

-Communications

Communication and internet network server room

Black PCBs are applicable in many types of communication applications, such as for base station controllers and station transceivers. In addition, you can also find the use of central office equipment, modems, and routers.

-Medical

Digital blood pressure monitor

Black circuit boards are common in a variety of medical applications, such as defibrillators, blood pressure monitors, and heart rate monitors.

Moreover, they are also in use for glucose meters, patient monitors, X-ray machines, and CT scanners. There are also in use for MRI machines and ultrasound machines.

-Military and Aerospace

Radar systems on the mast of a large ship

Black pcb solutions are common in a variety of military and aerospace applications. Such as night vision goggles, radar systems, and satellite communications systems.

You can also find them in missile guidance systems, aircraft navigation systems, and space exploration vehicles.

Process of applying solder mask colors on PCBs

This is how to apply solder mask colors on black PCBs.

STEP 1: Clean the board

Cleaning and rust removal is necessary before applying resin to the board. Oxidation also gets removed during cleaning.

STEP 02: Applying resin to the surface

When finishing the board cleaning, Seal the exposed film with a transparent blank film, then insert a syringe or plunger into it.

STEP 03: Spreading resin

Make a tiny transparent film and cover the resin positioned with it. And this ensures that the resin covers the entire board without leaving any gaps.

STEP 04: Squeegeeing resin

After the resin has been applied, use a squeegee to spread it evenly over the pcb board.

STEP 05: Placing solder mask

Epoxy the film of the solder mask over the board after you coat it. And then align the film correctly after that.

STEP 06: Curing the board

After placing the solder mask, cure the board with UV light. As this will harden the resin and make the black pcb board ready for use.

STEP 07: Peeling of the film

The final step is to peel off the film of the black pcb board. And your black pcb is ready!

How To Choose PCB Color

Choosing the right color for your PCB depends on more than just your preference.

It’s important to consider a number of technical and design factors to ensure optimal functionality, performance, and visual appeal.

Product Aesthetics

Products that are vibrant and playful could use brightly colored PCBs, whereas sleek products with modern designs could benefit more from black or metallic colors.

Market Preferences and Target Audience

The variety of segments prefer different colors. Simply conducting market research while also analyzing industry trends to get the preferred color of your target audience could go a long way in making your product successful.

Brand Identity

Choosing a unique and distinctive color for your PCB could help your product stand out from other products and help create a memorable experience for your potential customers.

This is especially important for products in a competitive landscape.

You can consider the color choices currently being used in the market and try to deviate from the normal while still maintaining visual harmony.

That kind of strategic thinking could offer your product an edge while reinforcing its brand and market position.

Signal Integrity and Electromagnetic Interference

The color of the PCB you choose could affect the electromagnetic interference issues and signal integrity.

For better EMI shielding, it’s better to opt for darker colors (like blue or black) that reduce the threat of interference and, thus, signal degradation.

However, lighter-colored PCBs are more prone to EMI as a result of their absorption properties and lower reflection.

Dissipation of Heat and Thermal Management

Many electrical devices, especially high-power ones, need good heat control and thermal management.

PCBs that are dark-colored do a better job at soaking up heat, therefore helping keep the device cool. Light-colored PCBs, though, reflect heat, which could lead to overheating problems.

Visibility and Contrast of Component Markings

On a PCB, silk screen labels and reference designators are valuable for part identification.

These matter when you’re putting together and testing the PCB as well as fixing it later.

The right PCB color can make the labels easier to read. That, in turn, makes assembly and fixing quicker and more efficient.

FAQs

other pcbs-Automotive Printed Circuit Boards with Surface Mounted Components

Is black PCB better than green?

There is no definitive answer to this question. It depends on your personal preferences and the project you’re working on. Black pcb boards tend to be more expensive than green ones, so it’s important to consider your budget when making a decision.

Does the color of PCB matter?

The color of your PCB can affect the overall aesthetic of your project. If you’re going for a sleek and modern look, black might be the way to go. If you want something more colorful, there are a variety of other options available.

Summary

PCBs are not just black, and there are many types of printed circuit boards that pcb manufacturers can make for a variety of applications.

Black PCBs are often in use in electronics because they provide an overall look that is sleek and professional.

However, other colors and finishes are available to create different effects or meet specific needs.

If you’re looking for a custom PCB, it’s important to understand the different types of PCBs so you can make the best choice for your project.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.