Efficient power and signal transmission is vital in modern electrical and electronic systems. Cable assemblies play a key role in maintaining stable connections and minimizing signal interference by bundling and routing cables in a structured, protective manner. This improves system reliability and efficiency across various industries, making cable assemblies essential for many applications.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

What is a Cable Assembly?

A cable assembly is a group of cables or wires bundled into a single unit to transmit power or signals efficiently. Typically, cable assemblies consist of multiple wires organized using ties, tapes, or protective sleeves.

Cable assemblies organize and protect cables or wires while ensuring system integrity and preventing wear and tear. They are designed to withstand environmental challenges such as extreme temperatures, vibrations, and moisture. Available in various sizes and configurations, they optimize space, simplify installation and maintenance, and protect individual cables.

These assemblies are critical links in electrical and electronic systems, ensuring secure and efficient connections. Their versatility makes them indispensable in industrial, aerospace, automotive, telecommunications, and medical applications, where durability and efficiency are crucial.

Cables Assemblies vs. Wire Harnesses

While wire harnesses and cable assemblies are used to organize wires and cables, they have key differences.

| Cable assemblies | Wire Harnesses | |

| Appearance | Cable assemblies typically group multiple cables within a jacket or sleeve, making them a single wire with two ends. | A wire assembly has branches running in different directions with multiple terminations on each breakout. |

| Images | ||

| Construction | A more complex construction featuring sheathing that protects against harsh environmental conditions. | A more straightforward solution that primarily focuses on organizing wires into a more manageable form by covering each wire individually and grouping them together loosely. |

| Application | This rigid structure improves durability and stress resistance, making cable assemblies more robust and well-suited for high-stress or outdoor applications. | Its flexibility allows for easier separation within devices where environmental exposure is minimal or compact organization is not a priority. |

Choosing between a cable assembly and a wire harness depends on the application. Choosing a custom solution provides greater flexibility and allows cable assemblies to be tailored to specific operational requirements.

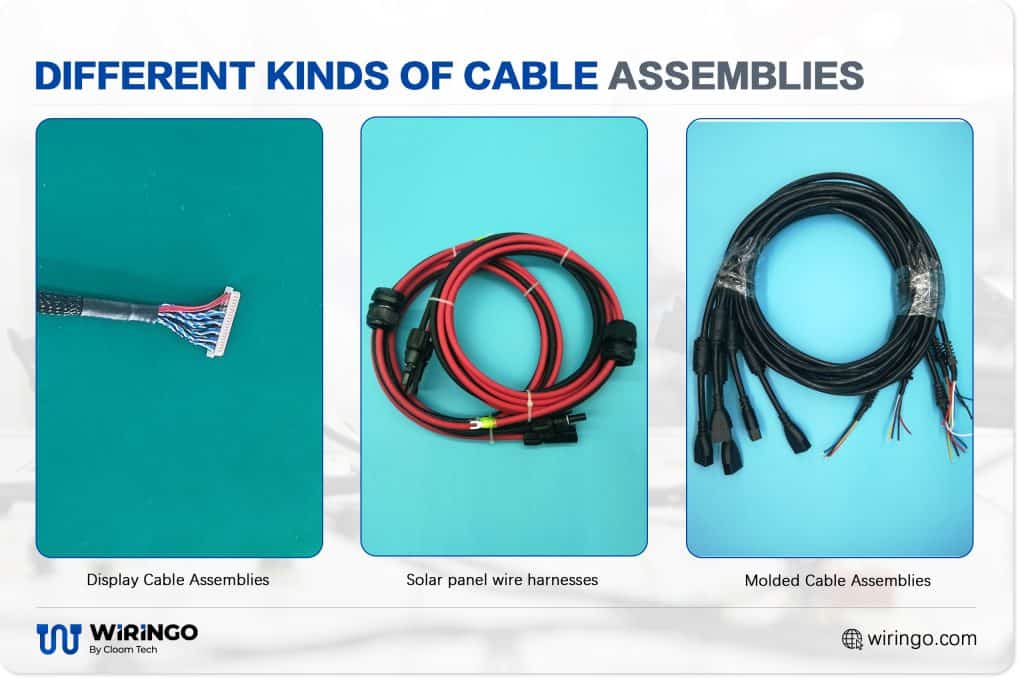

Types of Cable Assemblies

Cable assemblies are available in various types, each distinguished by its unique construction, material composition, and performance characteristics. These differences impact durability, flexibility, shielding, and resistance to environmental conditions, allowing each type to serve specific operational needs.

Below are the most common categories of cable assemblies.

- Coaxial Cable Assemblies: Used to transmit high-speed data or RF signals, coaxial cable assemblies for ultra-high speeds in excess of 1-2GHz require high-performance materials, connectors, and processing.

- Ribbon Cable Assemblies: Ribbon cable assemblies consist of multiple conductors arranged in parallel within a flat, flexible structure. Their design allows for easy organization, simplified connections, and high-density wiring. They are lightweight and space-efficient, making them ideal for compact setups.

- Molded Cable Assemblies: Molded cable assemblies are encased in a protective, molded material that enhances durability and strain relief. This construction provides high resistance to moisture, dust, and mechanical stress, ensuring long-lasting performance in demanding environments.

- RF/EMI Cable Assemblies: RF/EMI cable assemblies are designed to minimize radio frequency (RF) and electromagnetic interference (EMI). They feature high-quality shielding and precision engineering to ensure signal clarity and reliability, even in high-noise environments.

- LED Cable Assemblies: LED cable assemblies ensure secure electrical connections for LED lighting systems, handling variable voltages while maintaining efficiency and longevity. Their insulated, flexible design simplifies routing and installation.

- Circular Connector Cable Assemblies: Circular connector cable assemblies are designed with round, waterproof connectors that provide excellent mechanical and environmental protection. Their design ensures secure connections, resistance to vibrations, and enhanced durability in harsh conditions.

- Data and Video Cable Assemblies- D-Sub, USB, HDMI, DisplayPort: These cable assemblies include a specialized connector that ensures secure mating and shielding. They are reliable and can transmit multiple signals through a single connection.

- Power Cable Assemblies: Power cable assemblies are built to efficiently handle high voltage and current loads. They feature thick insulation, robust connectors, and durable sheathing to prevent damage and ensure safe power distribution over extended periods.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Benefits of Cable Assemblies

Custom cable assemblies provide tailored wiring solutions that meet specific needs. Unlike standard cables, they offer advantages such as:

- Adaptability: Their structured design simplifies installation and maintenance, making them ideal for applications where weight reduction and space efficiency are critical.

- Versatility Across Industries: In telecommunications, they facilitate seamless data transmission where conventional cables fall short. Their durability makes them suitable for harsh environments, including military applications, while their compact design supports the intricate wiring needs of advanced medical devices.

- Optimized Performance and Durability: These assemblies ensure durability and long-term performance by adhering to international manufacturing standards. With a longer lifespan and minimal energy loss, they provide a cost-effective solution, eliminating the need for frequent replacements.

- Improved Space Management and Organization: Custom cable assemblies streamline complex wiring systems by reducing clutter and optimizing space utilization. This makes them particularly valuable for applications where internal wiring efficiency is crucial, such as computing and industrial automation.

- Cost-Effective Solutions: Custom solutions are designed and tested to meet exact specifications, minimizing waste and maximizing efficiency.

Cable Assembly Applications

Custom cable assemblies are used across numerous fields.

- Aircraft: These systems require high-performance cable assemblies to ensure reliable communication, navigation, and power distribution. These assemblies must withstand extreme temperatures, vibrations, and electromagnetic interference.

- Agricultural: Modern farming equipment relies on durable cable assemblies for sensor integration, GPS tracking, and automated irrigation systems, ensuring seamless operation in harsh outdoor environments.

- Automotive: Vehicles incorporate custom cable assemblies for engine control, safety systems, and infotainment, optimizing performance while meeting strict durability and safety standards.

- Industrial: Heavy-duty cable assemblies are essential in manufacturing plants, power distribution systems, and construction equipment, providing robust performance in demanding conditions.

- Lighting: From architectural lighting to streetlights and stage lighting, cable assemblies ensure efficient power distribution and connectivity in various illumination applications.

- Medical: Advanced medical devices, such as imaging machines and patient monitoring systems, require compact and reliable cable assemblies to maintain accuracy and patient safety.

- Military: Defense systems, including communication networks, radar systems, and tactical vehicles, rely on rugged cable assemblies that withstand extreme environments and operational stress.

- Robotics and automation: Custom cable assemblies enable precise movement and control in robotic arms, automation systems, and AI-driven machinery, ensuring smooth performance and reliability.

- Solar: Solar energy systems depend on durable, weather-resistant cable assemblies to connect panels, inverters, and batteries for efficient power generation and distribution.

- Telecommunications: Reliable data transmission in fiber optics, networking infrastructure, and communication towers is made possible by high-quality cable assemblies designed to reduce signal loss and interference.

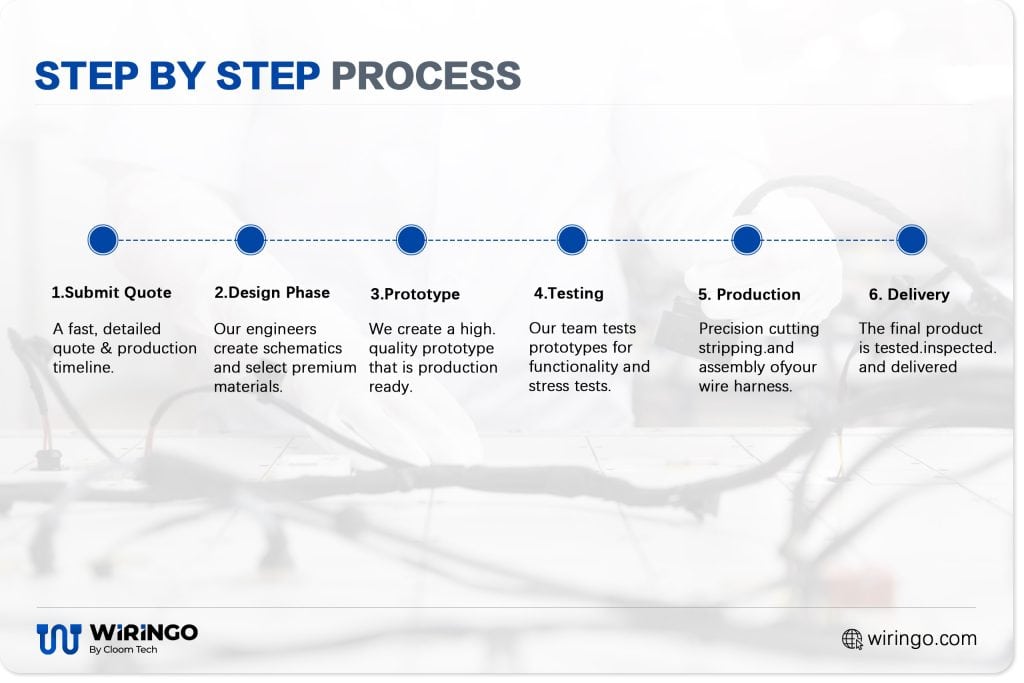

Manufacturing Process

The production of custom cable assemblies involves a structured process that ensures precision, durability, and efficiency.

- Requirement Analysis & Design: Define project specifications, including cable type, length, material, and performance needs.

- Material Selection: Choose conductors, connectors, protection measures, and other cable assembly components based on durability, flexibility, and environmental conditions.

- Prototyping & Testing: Develop a prototype to ensure the design meets technical and functional requirements.

- Cutting & Stripping: Precisely cut cables to the required length and strip insulation for connector attachment.

- Crimping & Soldering: Attach connectors using crimping or soldering techniques to secure electrical connections.

- Assembly & Bundling: Organize and bundle cables using protective sheathing or custom harnessing solutions.

- Quality Testing & Inspection: Perform electrical, mechanical, and environmental tests to verify performance and reliability.

- Packaging & Delivery: Finalize assembly, package securely, and prepare for shipment based on customer specifications.

Cable Assembly Testing

Assembly testing is crucial in defense, medical, and aerospace industries, where reliability and safety are paramount. Proper testing ensures that cable assemblies meet stringent performance standards and withstand harsh conditions.

- Continuity Test: This test checks for an uninterrupted electrical path in the assembly, ensuring no open circuits or shorts exist.

- Hipot Test: The High Potential (Hipot) test applies high voltage to the assembly to check for insulation breakdown. It verifies the assembly’s ability to withstand electrical stress without failure.

- Milliohm Test: This test measures the resistance of the cable’s conductors. Low resistance is necessary for efficient current flow, and this test helps confirm minimal electrical loss in the assembly.

- Pull Test: The pull test evaluates the mechanical strength of the cable assembly, ensuring that connectors and wires stay securely attached under force. It’s essential for durability and long-term performance.

- Flex/Bend Test: These tests simulate repeated cable movement to ensure it won’t break or degrade over time. Flexibility and resistance to wear are critical, especially in dynamic environments.

- Environmental Test: These tests expose the assembly to extreme conditions, such as temperature variations, moisture, and chemicals, to verify its ability to perform in harsh environments without failure.

Selecting a Cable Assembly Manufacturer

When selecting a cable assembly manufacturer, businesses should consider the following key factors:

- Certification: Ensure the manufacturer holds an ISO9001 certification, demonstrating their commitment to maintaining a quality management system that meets international standards.

- Experience and Expertise: Look for a manufacturer with significant experience in your specific industry and expertise in handling the relevant materials, specifications, and regulatory requirements for your application.

- Customization Capabilities: Assess the manufacturer’s ability to provide tailored solutions. They should be able to design and produce assemblies that meet your requirements, whether for complex, high-performance systems or simple, cost-effective options.

- Quality Control Processes: A reliable manufacturer should have a strong quality control system, including thorough testing procedures to ensure the final product meets the required standards and performs under intended conditions.

- Production Capacity and Lead Time: Consider whether the manufacturer can meet your production demands within your required timelines. Efficient lead times and capacity for scaling production are essential for maintaining business operations.

- Customer Support and Communication: Effective and responsive customer support is key for smooth collaboration. Ensure the manufacturer is easy to reach, transparent, and willing to work closely to meet your needs.

- Pricing and Value: While pricing is important, focus on the overall value. A good manufacturer offers a balance of competitive pricing without compromising on quality or service.

When you partner with Wiringo, you can be confident that these key factors will be met, and you’ll receive high-quality, reliable cable assemblies that meet your precise needs. Contact us today to learn more about how we can support your cable assembly requirements!

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.