Military cable assemblies are vital for the defense and aerospace industries. Cable assemblies must be built with high-performing materials and components that withstand harsh conditions, such as vibrations, high temperatures, and chemical exposure.

Given how critical these military cable assemblies are, finding a reliable manufacturer who delivers products that meet exact requirements can be challenging. However, we make it easier by bringing you ten reputable military cable assembly manufacturers known for their innovation, expertise, and compliance with strict military standards.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

10 Reputable Military Cable Assembly Manufacturers

Here, we present the ten most reputable manufacturers of military cable assemblies based on their experience and expertise in the field.

Wiringo

Founded: 2014

Headquarters: China

Company Overview

With over a century of experience, the company has established a strong reputation for providing robust, reliable, durable, customized cable assemblies that meet stringent industry standards.

Wiringo specializes in delivering tailored solutions for the military sector, including vehicles, radar and communication systems, and avionics. These products play a crucial role in the success of various military operations.

- Remote weapon control

- Air communication and navigation system

- Military equipment and ground machines

- Avionics

- Space force systems

- EMIs sensitive equipment

- Satellite and space shuttles

- Marine systems like ships and submarines

- Communication equipment

Wiringo selects high-quality components such as cables, wires, terminations, and connectors (38999 and circular connectors) to manufacture these military assemblies.

While designing and manufacturing cable assemblies, we ensure that every product meets MIL-SPEC standards, including MIL-STD-1460, J Standard-001 Class 3, and MIL-SPEC-2000.

In addition, we incorporate potting pre/over molding into cable assembly products. This makes cable assemblies abrasion-resistant, vibration-resistant, and waterproof according to IP67 and IP68 ratings.

With our innovation, precision design, and customer satisfaction, Wiringo is itar certified and widely regarded as a leading military wire harness manufacturer.

Client testimonial

As a defense contractor specializing in radar systems and advanced communications, I always looked for products that could meet my expectations.

- Ruggedization

Military cable assemblies must be rugged enough to withstand harsh environmental conditions, meet military-grade criteria, and perform for a longer time.

- Miniaturization

Critical military operations require the installation of miniature components in devices, machines, and vehicles. These miniature components are not only more robust and efficient than their bigger versions but also much lighter, flexible, and easy to integrate.

- Smooth operation under high-frequency

Military cable assemblies are supposed to offer electrical characteristics even while performing under high-frequency (4 Ghz-40GHz) electronic applications.

Thanks to Wiringo’s deep technical expertise and commitment to military-grade standards, we found military cable assemblies with unmatched reliability in extreme environments.

Their team has been incredibly responsible and works closely with my team to deliver customized solutions. The best part is their extensive manufacturing capabilities and strong supply chain.

They are able to meet our tight deadlines and handle complex projects with great precision.

Thank you, Wiringo, for being a trusted partner in our success.

Omega Leads, Inc.

Founded: 1961

Headquarters: Santa Monica, California

Company Overview

Omega Leads, Inc., is a trusted provider and manufacturer of cable assemblies and customized wire harnesses.

It also offers processing services, such as marking, wire cutting, and processing, to meet clients’ specific requirements.

The company has always prioritized durability and reliability in its military-grade wire harnesses and cable assemblies, marking them as capable of thriving in rigorous conditions.

All their military products are engineered to meet MIL-SPEC requirements, offering the highest quality and compliance with military regulations.

Focusing on customer satisfaction and innovation, the company has earned a reputation as a reliable partner for defense and military contractors seeking top-tier custom cable solutions.

Client testimonial

Omega Leads has been an invaluable partner in delivering wire harnesses and custom cable assemblies that meet high military standards. We are highly impressed with their attention to detail and ability to offer ruggedized products that work flawlessly in the field.

We have been working with them for a long time now, and they have never failed to satisfy us. We trust them to support our most demanding military projects on time and within budget.

—Senior Systems Engineer, Defense Technology Solutions

CMC

Founded: 2007

Headquarters: California

Company Overview:

If you are looking for critical custom-assembled MIL-SPEC wiring harnesses, Carr Manufacturing Company Inc. is one of the trusted providers.

Known for their durability, optimal performance in demanding environments, and high reliability, CMC offers everything from military equipment avionics systems to weapons control and marine systems.

Delivering both standards and custom solutions, this women-owned corporation strictly adheres to a wide range of military specifications, including MIL-DTL_5015, MIL-DTL-24308, MIL-DTL-38999, and many more.

Their innovative design capabilities, years of experience, commitment to excellence, and stringent quality control make them a reliable partner for every military and defense industry looking for long-lasting mission-critical performance.

Client testimonial

As a supplier of high-performance systems for the military, we require highly specialized requirements with tight deadlines.

CMC did not just fulfill our requirements but exceeded them by offering precision-engineered, custom-designed MIL-SPEC wiring and cable harnesses for new-generation vehicles.

We are highly impressed with their expertise in custom solutions and innovative braiding techniques. Thanks to the level of support and communication they maintain, every process of working with them becomes seamless.

—Project manager, Military Systems Engineering

Captor Corporation

Founded: 1965

Headquarters: Tipp City, Ohio

Company Overview:

Captor Corporation is an industry leader in providing high-quality military and aerospace cable assemblies, EMI filters, and wire harnesses.

Known for delivering MIL-SPEC compliant and custom military solutions, Captor Corporation offers a range of military-grade, high-quality, and precisely engineered products.

These wiring harnesses support applications such as field communication systems, aerospace systems, remote weapons control systems, and military communications equipment.

Their commitment to excellence is reinforced by their comprehensive testing procedures, which ensure every product adheres to the highest and most stringent industry standards.

Their skilled engineers and certified trainers deliver highly reliable products that deliver mission-critical performance for aerospace and military clients worldwide.

Client testimonial

Working with Captor Corporation has been a gamer changer for our military projects. We must say their commitment to quality, precision and customer satisfaction sets them apart from others.

The level of expertise they have in MIL-SPEC products is reflected in their products.

And the best part about them is they are trusted and reliable partners when it comes to meeting tight deadlines while maintaining high-quality in their products.

We are very thankful for their incredibly responsive team and look forward to collaborating with them for our future projects.

—John Peterson, Director of Engineering

Consolidated Electronic Wire & Cable

Founded: 1919

Headquarters: Chicago, Illinois

Company Overview:

With over a century of experience, Consolidated Electronic Wire & Cables has designed and manufactured wire and cable solutions for different industries.

The company’s military and aerospace solutions meet the most stringent MIL-SPEC standards and deliver exceptional performance in the harshest environments, ensuring operational success.

Their product range suits all types of applications, including space shuttle systems, jet cockpit control modules, and advanced military communication systems.

All wiring harnesses and cable assemblies can endure seawater corrosion in marine systems, vacuum space of aerospace equipment, and desert climates of military vehicles.

Their products’ ruggedness, reliability, and durability make them a trusted partner for many military, aerospace, and industrial clients.

Client Testimonial:

We got in touch with Consolidated Electronic Wire and Cable through a reference and we must say that we would never regret our decision.

The level of expertise in military and aerospace applications these guys have is simply unmatchable.

Whatever needs we specify, they deliver us customized products exactly matching our requirements on time without compromising quality.

We are lucky to partner with them for our military and aerospace solutions. Thanks guys!

—James Caldwell, Program Director, Advanced Aerospace Systems

EPEC

Founded: 1952

Headquarters: Massachusetts, USA

Company Overview:

Having over 70 years of experience, EPEC is a leading provider of high-quality military cable assemblies and wire harnesses.

With its state-of-the-art technology and extensive manufacturing capabilities, EPEC offers a comprehensive suite of services like custom cable design, fabrication, environment testing, and high-voltage isolation testing.

Having full compliance with IPC-A-620, IPC/WHMA-A-620, and NASA soldering specifications, each product meets rigorous military standards.

Focusing on reliability, precision, innovation and quality, EPEC has been supporting various military and aerospace missions with its world-class products.

Client Testimonial:

We have been working with EPEC for several years now, and their incredible expertise in military cable assemblies and wire harnesses has been invaluable to our projects.

EPEC consistently delivers military cable harnesses with high precision, reliability and compliance with MIL SPEC standards that we always look for.

We are especially impressed with their attention to detail and strong focus on documentation, providing us with confidence that every product meets high standards and is built to demanding specifications. We look forward to collaborating with them in the years to come.

—John M., Senior Project Manager, Defence Contractor

Connectronics Corp

Founded: 1988

Headquarters: Toledo, OH

Company Overview:

Connectronics is a leading manufacturer and supplier of high-performance military cable assemblies. Having ISO 9001:2015 certification and ITAR registration, the company mainly specializes in rugged, military-grade solutions.

Their product range includes custom cable assemblies used in different applications, such as avionics, satellite, and ground equipment.

All their products meet the highest industry standards and military specifications.

The company guarantees the reliability of its products in the most challenging environments by adhering to Supplier Quality Assurance Requirements (SAQR).

Due to its long-lasting and cost-effective solutions, it has been a trusted partner for various military clients.

Client Testimonial:

Thanks to the exceptional performance of Connectornics’s military-grade connectors and custom cable assemblies.

The products have always met our requirements and performed incredibly well in our missions.

The best part is their quality assurance process, which ensures that every product meets the toughest military specifications.

—David P., Senior Engineer, Aerospace and Defense Contractor

Carrio Cabling

Founded: 1988

Headquarters: Colorado City, Colorado

Company Overview:

With over 32 years of experience, Carrio Cabling is a leader in designing and manufacturing high-quality and rugged custom military cable assemblies and interconnect solutions.

Entirely made in the USA, their cable assemblies, RF coaxial cables, and connectors are perfect for the most demanding environments in the military, aerospace, and defense industries.

Their products, backed by the ISO 9001:2015, UL, and IPC certifications, ensure high performance, durability, and exceptional reliability.

Carrios’s fully integrated US-based manufacturing process, commitment to American-made quality, and unmatched customer service make them a trusted name among military and aerospace partners.

Client Testimonial:

Carrio cabling has been our go-to vendor for quite a long time now. They have always delivered on time. They are quite competitive when it comes to pricing.

We have found them pretty meticulous when it comes to quality. Their design and engineering team is quite capable of rendering customization as clients require.

We look forward to continuing our partnership with Carrio Cabling going forward.

—P Paul, Procurement Head

Custom Wire Industries

Founded: 1968

Headquarters: Wisconsin, USA.

Company Overview:

Based in the USA, Custom Wire Industries specializes in delivering mil-spec products, including sensor cables, fiber optic cables, coaxial cables, shielded cables, wiring harnesses and ribbon cables.

The company follows stringent military regulations and industry standards, ensuring reliability and performance in critical military applications.

Their products can withstand extreme heat, extreme conditions, and high-frequency applications, ensuring clear, uninterrupted communication and operational success.

If you are looking for high-quality, durable military solutions with quick turnaround times, Custom Wire Industries is a trusted name.

Client Testimonial:

Custom Wire Industries truly lives up to its name. They have always delivered the promised custom solutions to us.

Their manufacturing facilities comply with top industry standards and military regulations.

They have helped us meet tight deadlines and we have been able to secure good business, all thanks to them.

—Harry K, Strategic procurement manager

Amphenol Unlimited Services

Founded: 1982

Headquarters: Oconto, Wisconsin

Company Overview:

Are you looking for high-quality military wire harnesses and cable assemblies? Amphenol Unlimited Services is the right choice.

Having ITAR-certified plants in the USA and Mexico, Amphenol produces military-grade solutions that meet stringent Department of Defense (DoD) requirements, including compliance with the Berry Amendment And DFAR 252.225-7014.

Their products perfectly meet the demands of military electronics, vehicle applications, and telecommunications, delivering high quality, flexibility, and reliability.

Also, the company has been a trusted partner for organizations as they offer cost savings in their military wire harnesses and cable assemblies.

Client Testimonial:

We have been working with Amphenol Unlimited Services for a long time; thanks to their invaluable support, we are able to successfully secure and maintain our military contracts.

Renowned as an ITAR-certified manufacturer, their wire harnesses are available at competitive prices, a must for the cost-sensitive military industry.

Thanks to their responsive and knowledgeable team, who are meeting exact demands in tight deadlines. Looking for more collaboration in the future!

—James R., Senior Procurement Manager, Aerospace Defense Contractor

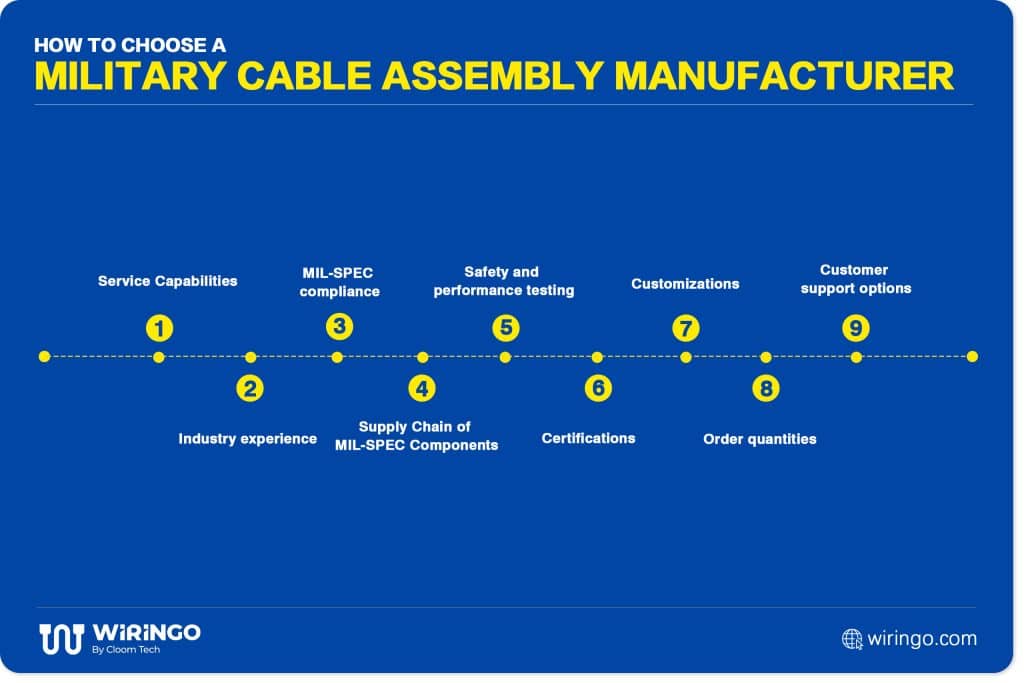

How to Choose a Military Cable Assembly Manufacturer

Here, we list certain factors to consider when selecting your military cable assembly manufacturer.

Service Capabilities

Always look for a manufacturer who offers a broad range of services, including custom-designed assembly, testing, and packaging.

For military and aerospace applications, look for technology such as EMI shielding, radiation protection, high-temperature tolerance and environmental resistance in the products, as only such products can thrive in tough military environments.

Industry experience

Choose a manufacturer with many years of experience in the military and defense sector. This can ensure consistency and the right quality control in the products.

Also, only an experienced manufacturer knows the high-risk nature of military projects and strictly adheres to the regulatory and compliance mil-spec requirements.

MIL-SPEC compliance

MIL-SPEC standards such as MIL-DTL-38999, MIL-PRF-55339, and MIL-DTL-5015 specify detailed requirements for cable assemblies and overall construction to meet the rigorous demands of military operations.

Compliance with these standards assures the highest quality, performance, and safety of the products.

Supply Chain of MIL-SPEC Components

Several mil-spec standards differentiate military wires and connectors from others. Some private organizations such as SAE, ANSI, and NEMA have also developed their standards.

A mil-spec component must follow specific standards to fall into the category, perfectly suitable for medium- and high-temperature applications to perform at maximum, even under high mechanical stress.

Check whether your manufacturer supplies you with components compliant with these standards.

Safety and performance testing

Military cable assemblies had to undergo harsh environmental conditions, including vibrations, chemical exposure, and extreme temperatures.

Check whether the manufacturer performs safety and performance tests such as MIL-PRF-85045 and MIL-STD-810.

Certifications

Choose a manufacturer with certifications like ISO 9001 (quality management) and ITAR (International Traffic in Arms Regulations).

These certifications prove that the manufacturer complies with global industry standards for quality and security and follows strict guidelines.

Customizations

Military applications often require unique configurations, so look for a manufacturer who can offer tailored solutions. Custom manufacturers can accommodate your specific needs related to insulation types, wire lengths, or specified connectors.

Order quantities

Choose a manufacturer who can deliver your order quantities on time, whether a prototype or a large-scale production. Ensure they can scale their production line according to your requirements while maintaining consistent quality.

Customer support options

Always look for a manufacturer with a responsive customer support system with clear communication channels, post-production services, and engineering support.

There must be ongoing support to make updates and adjustments and avoid costly delays.

Select the Right Manufacturer for Your Business

If you want tailored cable assembly solutions for your military systems, contact Wiringo today! Our high-performing cable assemblies can help you achieve optimal results in all your military defense and aerospace projects.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.