Wiring requirements vary from individual to individual. Your wiring application area and functionality will dictate the design, voltage, current capability, size, and colors, among other variables.

Therefore, dealing with a China wiring company that takes your needs seriously is essential.

Apart from meeting customer’s requirements, China wiring is under certain safety, design, and installation standards.

The rules and regulations are formulated by GB standards (GuoBiao Standards), China Compulsory Certification (CCC), and the International Electrotechnical Commission (IEC). The IEC tries to harmonize the wiring standards globally. It has proven difficult as every country varies environmentally and structurally regarding electrical appliances, machines, and automobiles.

This article will provide detailed information on China’s wiring. From wiring and cable harnessing, color codes, designing, testing, and other wiring processes.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

CHAPTER 1: Understanding Cable Assemblies and Wiring harnesses

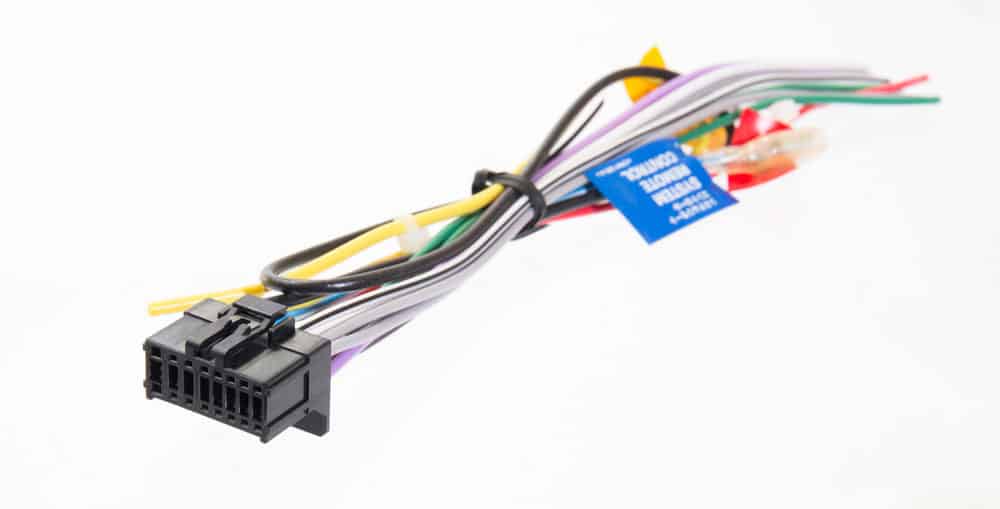

A cable harness is a combination of two or more conductors that are insulated with a more intensive exterior product. Mostly, a cable will have a positive wire to carry current, a neutral one to complete the electrical path, and a grounding wire. After that, the whole combination is covered with heavy-duty materials such as shrink-wrapped thermoplastic, rubber or vinyl sheath.

Cable harnessing is a custom-designed assembly to ensure the product meets your specific logistic and structural requirements. Also, other factors are considered, for instance, temperature, humidity, size, shape, chemical substance exposure, fiction, colors and area of application.

Wire Harness Design

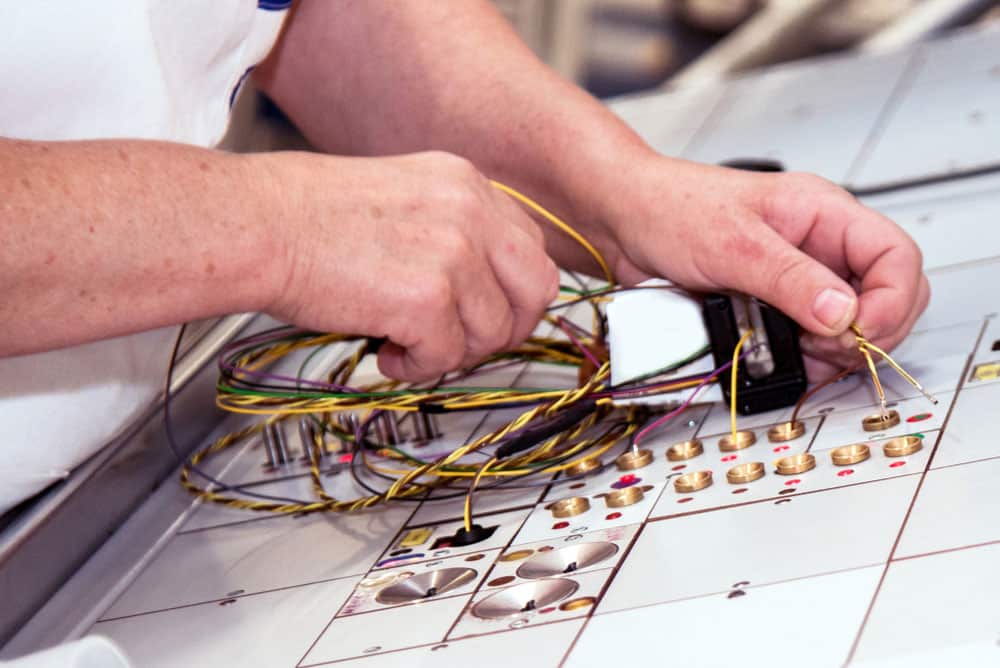

Designing begins with the development of a blueprint for manufacturing and a pinboard for hosting the harness. The pin or assembly board is a representation of the harness. It indicates all the components and their location and serves as a working table for the wire harness.

The wires to be assembled come in a master reel, cut into the desired lengths, and printed for labeling and bar codes where required. With the required lengths, the wires are stripped off at the end to fit the terminals and connector housing where necessary.

The wires are placed on the assembly board and attached with suitable lacing, wire ties, tapes, strings, weaves or straps, or a combination of the components.

Over time, there have been attempts to advance manual wire harness designing to automation, but as the process involves many activities, most of the stages of the process remain manual. Nevertheless, some parts of the process have been automated for speed and accuracy.

Cable Assembly Process

- Cutting and shaping cables to the required lengths

- Installing the wires, cables, and components (subassemblies) on the assembly or pinboard

- Routing and attaching subassemblies with terminals and through other connector housing or sleeves

- Attach the subassemblies to the board with wraps, weaves, ties, or tapes

- Where possible, soldering of wire ends with a solder machine

Nevertheless, this is just a general process of what cable assembly entails, not a specific step-to-step process. Also, automation of the whole process has proven difficult as manual cable harness is more cost-effective considering the numerous activities involved. However, the initial parts of harnessing and kitting can somehow be automated.

Cable Harness Testing

Before releasing the wire harness to you, we ensure the cable harness meets the geometric and electrical requirements through thorough testing and evaluation by our experienced team. Repeat purchases of similar products over the years have allowed us to develop standard products and save time in the harnessing process, testing, and installation.

What is an Automobile Wire Harness?

Automobile wire harnesses can simply be described as the assembly of electrical cables for the transmission of signals (wire harnesses) in automobiles. Wire harness plays an important role in some functionality of automobiles and space/aircrafts considering the amount and length of wires involved in their construction. Wire harness ensures the wires are more bound and thus safe from damage through abrasion, vibrations, and moisture.

Also, the constriction of the wires saves much space, and since they are bound into slave sleeves, the possibility of electrical fires occurring is minimized.

CHAPTER 2: China Wiring Benefits

China is becoming the focus of connectors and cable assemblies. Here are a few benefits of hiring a Chinese-based wire manufacturing company.

Sourcing raw materials at cheaper rates

As more and more international Electronic Manufacturing Service (EMS) providers set up shop in China, the country is rapidly expanding its role as the world’s primary hub for electronic production.

In 2017, China imported a total of $1.62 billion of connector items, demonstrating the country’s status as a major buyer of electronic components. More than 600 genuine connectors and cable parts suppliers operate on the Chinese mainland.

China Manufacturers may benefit from bulk purchasing discounts on raw materials. The savings from these reduced prices will benefit the client in many ways.

The wire extrusion industry’s easy access to raw materials is attributed to a large pool of skilled workers, rapid production cycles, and competitive prices.

Prompt and timely deliveries

Delivery times that won’t leave you waiting indicate that the manufacturer isn’t serious about doing business. If there are problems on their end, they will be honest about them, working to minimize the impact on your organization. The same, however, cannot be true for producers who are neither skilled nor moral.

In China, however, the trade names are working on faster deliveries, Thus providing you with products in less turnover time. That way, you don’t have to wait for quality cable assembly for longer periods.

Lower production costs

There will be huge costs if you start making wire harnesses. All the costs associated with running the business will fall on you, whether direct (labor and equipment) or indirect (overhead, healthcare, tax, and bonuses). Your product prices will rise over time, driving away buyers unless you take action.

However, moving production to a lower-labor country can reduce your overhead spending and labor and materials. And when labor costs are low, you’ll be able to sell your wares to consumers at much-reduced costs. The best part is that your wire harness will be of the highest quality, even if you lower the production and labor costs.

Superior service

A professional wire harness manufacturer will have decades of expertise in making wire harnesses and other assemblies. The manufacturer has undoubtedly become an authority in wire harnesses thanks to their extensive experience in the field.

If you build your team to produce wire harnesses, the chance is that you miss out on expert advice. Also, it will use up all of your company’s resources, which is especially problematic for startups and SMBs.

Hence, hiring professionals from china will be helpful if you want your cable harnesses made in the safest ways possible. It would also free up your time to concentrate on other weak spots in your company.

Fair contract negotiations

If you’re searching for a manufacturer, you should know some facts. Some firms may trick you into doing business with them by making exaggerated or misleading statements.

Most Chinese companies go for fair negotiations right from the beginning of the contract. Hence, you just need to look out for a good reputation company, and voila, you got through the problem.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Chapter 3: Chinese Wiring Color

Manufacturers, contractors, engineers, electricians, and traders all over the globe use different electrical wiring color codes for electrical distribution in residential homes and industrial buildings and wire and cable installation.

Some power cable and wire color codes are required, while others are optional. Using a standard wiring color code during installation provides several key benefits.

For example, using consistent colors makes it easier to identify the ground, line, and neutral wires to enable easier tracing of circuits, thus facilitating troubleshooting and maintenance tasks.

Furthermore, having a standardized color coding system helps protect electricians as it is easier to differentiate live wires from neutral ones.

Sticking to a set color code saves valuable time when dealing with electrical systems since technicians and electricians don’t have to spend as much effort figuring out what type of wire is connected to what, as the colors immediately provide the information.

Overall, standardized wire and cable color codes create a safer and more efficient environment for everyone.

Various colors are used for different cables and wires in different regions for single-phase, alternating current (AC), direct current (DC), and three-phase for design and installation according to local rules, regulations, and codes.

One of the most popular is the International Electrotechnical Commission (IEC), which most European countries, the UK and Argentina, follow.

Another popular code is the National Electric Code (NEC) that Canada and the US follow.

Now, let’s discuss the wiring color codes for China that detail the standard wiring color codes for fixed and flexible cables.

Flexible Cable

The wire color codes from this category are power cables, lamp cords, and extension cables:

- Neutral (N) – blue, black

- Line (L) – red, green, yellow

- Protective Earth (PE) – yellow-green striped

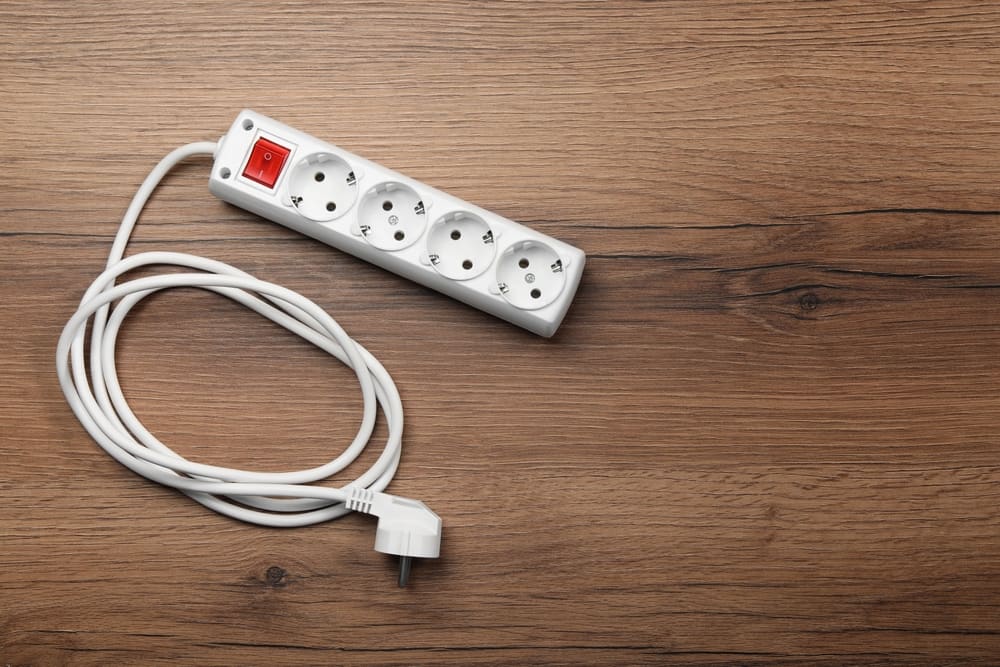

Caption: Extension Cord

Fixed Cable

The wire color codes from this category are three-phase color chats, including cables behind, on, or inside walls.

- Neutral (N) – blue, black

- Three Phase, Line 1 (L1) – yellow

- Three Phase, Line 2 (L2) – green

- Three Phase, Line 3 (L3) – red

- Protective Earth (PE) – yellow-green striped

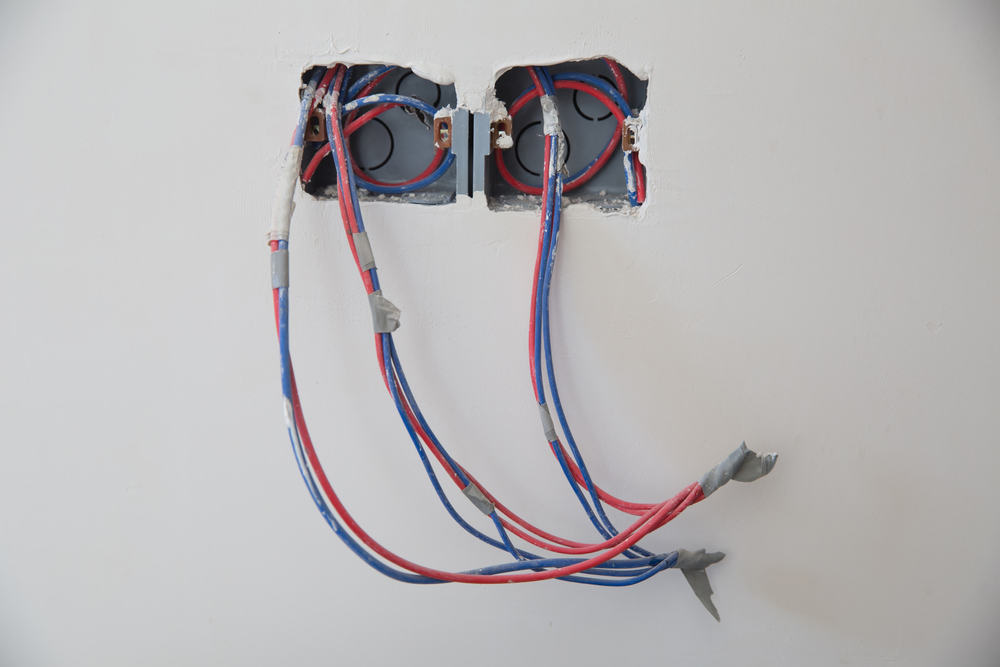

Caption: Electrical Wiring Gong Inside a Wall

CHAPTER 4: What to Look for in China Wiring Manufacturers

Wire or cable harness may seem like a typical job until you come to think of it regarding what and how much you could lose if there is an application of a poorly manufactured cable harness. Damage or failure of a wire harness could impact the devices connected to it. Consequently, you must have sufficient information on choosing the right manufacturer for your harness.

Tips for Evaluating Wire Harness Manufacturers

The quality, durability, and life of your wiring harness will have much to do with the manufacturer. Below are tips you can consider to choose the suitable manufacturer and manufacturer research.

The company history

A manufacturer’s longevity in China wiring is an assurance of a well-versed provider in the wiring harness. More time spent in the industry means accumulating knowledge, skills, practices, better methodologies and acquiring quality materials.

Also, it would help if you did not worry about discovering that your manufacturer closed the business without getting the job done. Like every industry, businesses start and get closed; a more rooted China wiring manufacturer will advantageously have you at peace.

Skill level and experience

As discussed earlier, automating the whole wiring harness process has become impossible. Therefore, standardization is less achieved with manual working thus making it easy for you to identify a quality finished product. It will depend on the level of expertise of the designers and manufacturers.

Quality control is also an aspect you can consider about your manufacture. It is mainly implemented during testing. Therefore, the company should have invested in high-testing technology. Efficient and optimal testing guarantees that your requirements for a quality and reliable wiring harness will be met.

Does the company cost complement the quality?

It is human nature to relate expensive with quality. However, your wiring harness rmanufacturer should be able to meet your component and product quality needs so that you will be happy to pay for it. The low cost of the service and the product could seem like a great deal, but look out, it does not come to bite you in the back.

Proper communication and interaction

Apart from working to achieve a quality product, the manufacturer should be attentive to your specific needs and put them into action. Additionally, when you reach out, the manufacturer should respond immediately and address your concerns. Communication should not be frustrating.

FAQ

Is Blue Wire Positive or Negative in China?

In the past, China used to use its old wiring color code; however, today, they use the IEC power circuit wire codes.

| IEC OLD & NEW AC WIRING COLOR CODES | |||

| PHASE SUPPLY | CABLE & WIRE | OLD IEC CODES | NEW IEC CODES |

| 3 – PHASE | LINE 1 (L1) | BROWN, BLACK | BROWN |

| LINE 2 (L2) | BROWN, BLACK | BLACK | |

| LINE 3 (L3) | BROWN, BLACK | GREY | |

| EARTH / GROUND (PE) | YELLOW-GREEN STRIPED | YELLOW-GREEN STRIPED | |

| COMMON | NEUTRAL (N) | BLUE | BLUE |

| 1 – PHASE | LINE (L) | BROWN BLACK | BROWN |

| China Old AC (Single & Three-Phase) Wiring Color Codes | ||

| Phase Supply | Cable and Wire | Color Code |

| Three – Phase | Line 1 (L1) | Yellow |

| Line 2 (L2) | Green | |

| Line 3 (L3) | Red | |

| Earth / Ground (PE) | Yellow Green Striped | |

| Common | Neutral | Black or Blue |

| 1 – Phase | Line (L) | Yellow |

Is Red Negative in China?

For DC, China sticks to the IEC color codes. However, you shouldn’t trust the cable insulation colors as electricians use the old and new color codes for DC and AC. Therefore, using a tester to confirm the negative, positive, neutral, and phase wires is always best.

| IEC DC WIRING COLOR CODES | ||

| Two-Wire Undergrounded DC Power System | Negative (L-) | Grey |

| Positive (L+) | Brown | |

| Two-Wire Grounded DC Power System | L+ (of a -VE Grounded) Circuit | Brown |

| L- (of a +VE Grounded) Circuit | Grey | |

| ‘M,N’ +VE (of a +VE Grounded) Circuit | Blue | |

| Three-Wire Grounded DC Power System | Blue | |

| Three Wire Grounded DC Power System | Positive (L+) | Brown |

| Negative (L-) | Grey | |

| ‘M, N’ Mid Wire | Blue | |

| Earth / Ground (PE / PG) | Yellow Green Striped | |

Conclusion

Wiring, whether wire or cable harnessing, is a task that requires expertise and experience for a quality end product. We at Wringo are committed to providing outstanding wire harness solutions. Through our expert technicians who understand and are familiar with the required standards of China wiring, we deliver nothing short of the best.

With years of experience in wiring and manufacturing related materials, we have mastered the skill and perfected the art of understanding and making your ideas come to be. We deal with highly qualified electrical engineers in designing cable harnesses, thus ensuring quality from the start.

Aside from acquiring standard processes, we also develop a methodology to develop some of our tools, plastic, dies, glass, metal, and synthetic materials. To bring all the materials and tools together, we have a highly designed and developed process with qualified technicians to ensure the manufacturing process goes smoothly and efficiently.

After that, we are solely responsible for testing that every harness will provide its optimum function. We confirm its durability under different environments, desired functionality and the place of application. Ultimately, we come up with quality-defined standards for manufacturing a cable harness.

Contact us any time; we will be glad to serve you.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.