Coaxial cables are crucial in various industries, including robotics, electronics, and industrial automation. The right coaxial cable ensures optimal signal transmission, minimizes interference and protects sensitive equipment. However, choosing the wrong type can lead to signal degradation, increased electromagnetic interference (EMI), and damage to equipment.

Different coaxial cable types are used for specific applications, ensuring stable performance in industrial and commercial environments. This guide explores the most common types of coaxial cables, their uses, and how to select the right one for your needs.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

How Do Coaxial Cables Work?

Coaxial cables are designed to transmit signals with minimal interference, making them essential in telecommunications, broadcasting, and data transmission. Coaxial cables ensure high-quality video, audio, and data transmission by preserving signal integrity in noisy electrical environments.

Their shielding blocks external noise and EMI, ensuring stable, clear transmissions.

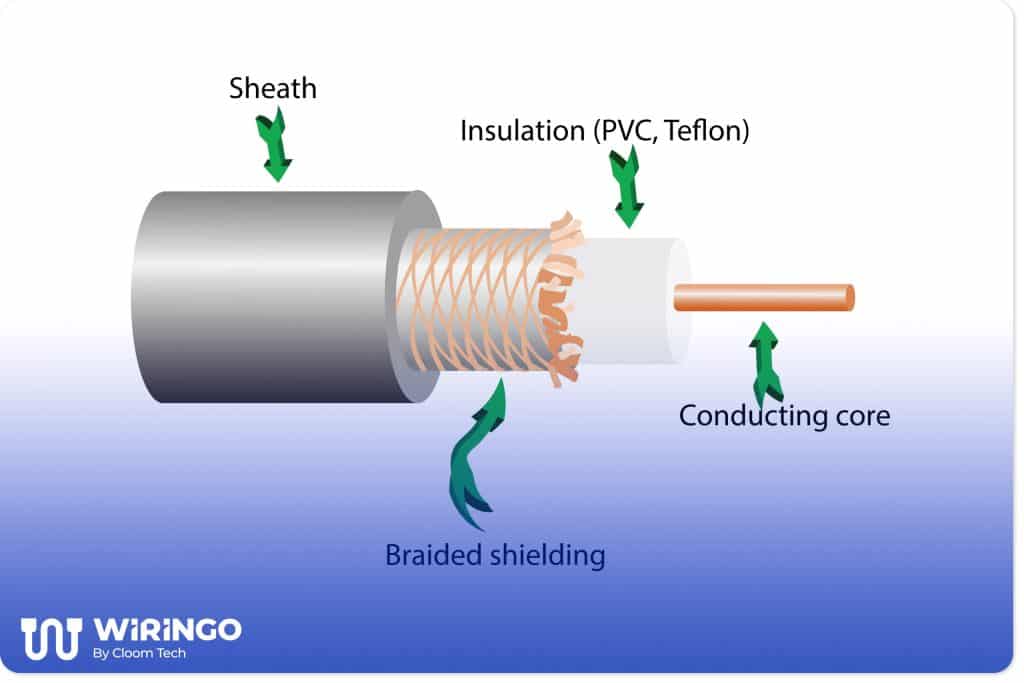

A coaxial cable consists of four essential components:

- Center Conductor – Carries the electrical signal.

- Dielectric Insulator – Separates the conductor from the shielding and maintains signal integrity.

- Shielding Layer – Protects against EMI and signal loss.

- Outer Jacket – Provides durability and environmental protection.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Choosing the Right Coaxial Cable

Selecting the right coaxial cable ensures reliable transmission, minimizes interference, and maintains long-term performance across applications.

RG-Series Coaxial Cables: Versatile and Reliable

RG-series coaxial cables are widely used in homes, businesses, and industrial setups due to their versatility and reliability. These cables come in different variations, each designed to optimize signal transmission based on specific application needs.

Differences in shielding, conductor size, and dielectric materials determine their suitability for short- or long-range communication, high-frequency signals, and resistance to interference. Understanding these variations ensures proper selection for applications such as broadband internet, video distribution, and RF communication systems.

Common Types and Uses:

- RG-6/U – Ideal for cable TV, satellite, and broadband internet.

- RG-8/U – Used in high-frequency applications and two-way radio systems.

- RG-11/U – Best for long-distance cable TV and high-frequency signals.

- RG-59/A/U – Suitable for CCTV and video signal transmission.

| Type | Mil Designation | Impedance (Ohms) | Center conductor size(AWG) | Dielectric | Outer Diameter (Inches) | Shield Construction |

| RG-6/U | M17/2-RG6 | 76 | 18 | PE | 0.332 | Braid |

| RG-8/U | 52 | 10 | PE | 0.405 | Braid | |

| RG-11/U | M17/6-RG11 | 75 | 14 | PE | 0.405 | Braid |

| RG-59/A/U | M17/29-RG59 | 73 | 20 | PE | 0.242 | Braid |

Hardline Coaxial Cables: Designed for High-Power Signals

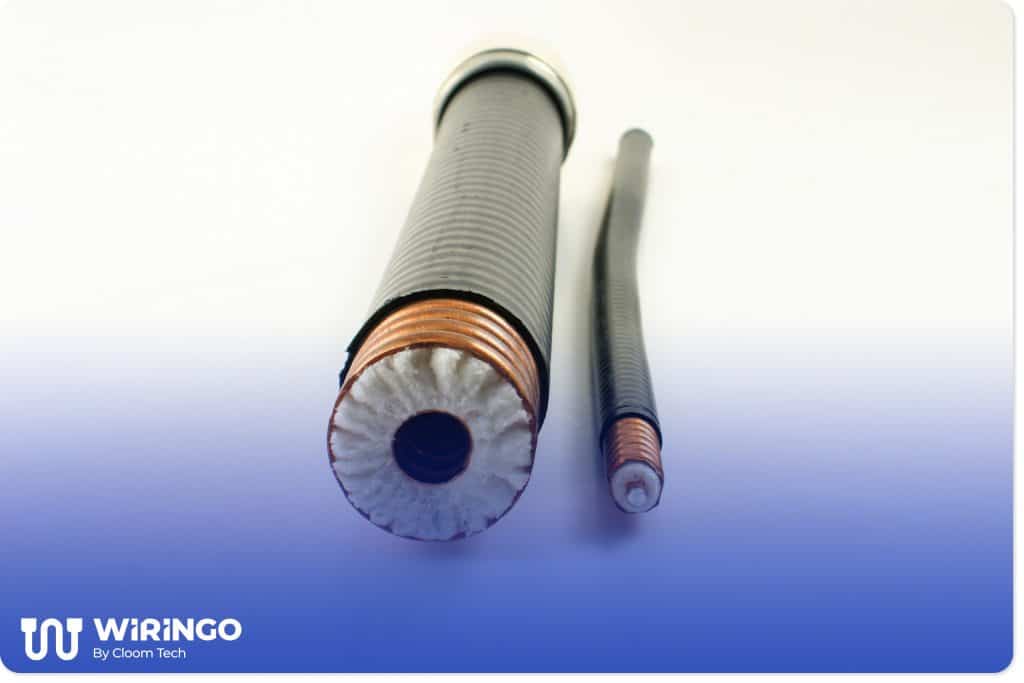

Hardline coaxial cables feature solid metal conductors, round copper tubing, and a combination of metals like aluminum or copper as a shield. They are designed to minimize signal loss and withstand extreme environmental conditions, such as high temperatures and mechanical stress.

Their robust construction ensures optimal performance in critical applications, including military radar systems, high-power RF transmitters, and cellular infrastructure, where uninterrupted signal integrity is essential.

Best For:

- Military and industrial communications such as encrypted battlefield networks and secure military radio transmissions.

- Radio and television broadcasting, including high-power AM/FM radio towers and HD television transmission.

- High-frequency transmission in telecommunications, such as backbone infrastructure for cellular networks and satellite uplinks.

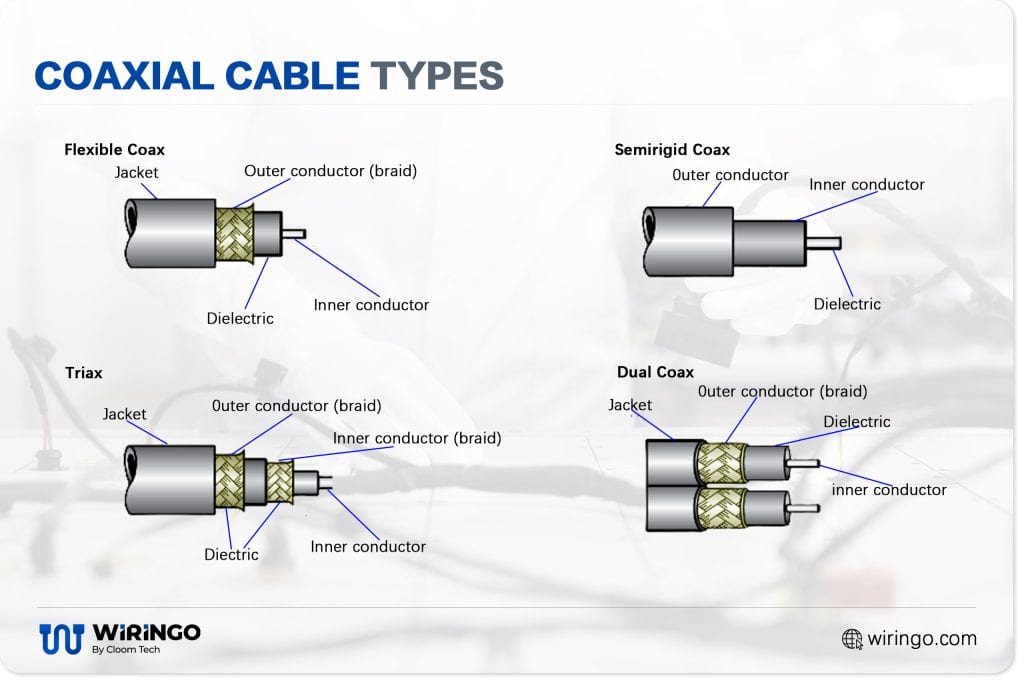

Semi-Rigid and Hand-Formable Coaxial Cables: Precision for Specialized Applications

Semi-rigid cables feature a solid copper outer sheath for superior shielding over braided cables. While less flexible, they deliver enhanced high-frequency performance, making them ideal for aerospace, medical, and defense applications.

Hand-formable variants retain superior shielding while allowing easy installation and routing in complex setups. They are ideal for customized wiring solutions in RF measurement systems and advanced medical imaging devices.

These cables offer excellent phase stability and low attenuation, ensuring reliable performance in demanding electromagnetic environments.

Best For:

- RF measurement equipment, such as spectrum analyzers and signal generators.

- Medical imaging systems, including MRI and ultrasound machines.

- Aerospace testing used in avionics systems and satellite communication setups.

Twinaxial and Triaxial Cables: Extra Shielding for Sensitive Signals

Twinaxial cables have two central conductors instead of one. In addition to reducing cable loss and ground loops, they offer enhanced protection from capacitive fields and low-frequency electromagnetic noise.

They excel in differential signal transmission, minimizing reflections and crosstalk while enhancing noise immunity in high-speed computing. Ideal for low-frequency digital and high-speed data applications, they are widely used in Ethernet networks, data centers, and avionics.

On the other hand, triaxial coaxial cables have an additional copper braid that acts as a shield and protects the cable from electromagnetic interference from outside sources. Generally, cables with triaxial connectors offer increased bandwidth and interference rejection, improved signal-to-noise ratios, and reduced cable losses and loading. Triaxial cables ensure exceptional signal integrity in broadcast, medical imaging, and precision instrumentation applications.

Best For:

- Data centers for high-speed networking, such as 10G and 40G Ethernet connections.

- Studio-quality video transmission, including professional broadcasting cameras and editing suites.

- Industrial automation requiring high-frequency performance, such as factory robotics and precision testing equipment.

Low-Loss and Flexible Coaxial Cables: Balancing Performance and Flexibility

These are updated versions of RF coaxial cables with higher flexibility, lower cost, and greater installation cost.

Low-loss coaxial cables are engineered to minimize signal attenuation over long distances, ensuring efficient signal transmission for applications requiring high-frequency stability. These cables utilize advanced dielectric materials and optimized shielding to reduce power loss and improve impedance consistency. They are instrumental in environments where maintaining strong signals over extended cable runs is critical, such as cellular network installations, military communication systems, and satellite uplinks.

Flexible coaxial cables are easy to install and maneuver in tight or confined spaces without compromising electrical performance. Their design incorporates braided shielding and stranded center conductors, allowing greater flexibility while maintaining signal integrity. These cables are widely used in RF communication setups, GPS antennas, and portable electronic systems where mobility and adaptability are key requirements.

Common Types and Uses:

- LMR-100 – Ideal for short-range wireless applications and portable antennas.

- LMR-200 – Used for Wi-Fi networks, GPS connectivity, and surveillance systems.

- LMR-240 – Suitable for mobile antennas, amateur radio, and RFID applications.

- LMR-400 & LMR-400 Ultraflex – Best for high-power signal transmission in demanding RF environments.

- LMR-600 – Provides excellent low-loss performance for long-distance and high-power communication systems, including broadcasting and base station setups.

| LMR coax cable | Impedance | Core size | Dielectric type | Nominal attenuation @850 & 1900 MHz/100 ft |

| LMR 100 | 50 ohms | 0.11mm | PF | 850/22.8dB;1900/39.1dB |

| LMR 200 | 50 ohms | 1.12 mm | PF | 850/9.6dB;1900/14.6dB |

| LMR 240 | 50 ohms | 1.42mm | PF | 850/7.2dB; 1900/11.2dB |

| LMR 400 | 50 ohms | 2.74mm | PF | 850/3.8dB; 1900/5.8dB |

| LMR 600 | 50 ohms | 4.47 mm | PF | 850/2.4dB; 1900/3.8dB |

Matching Coaxial Cables with the Right Connectors

Coaxial cable connectors are used wherever coaxial cables are used. These connectors are highly durable and versatile, even in rough environmental conditions.

Common Coaxial Cable Connectors:

- BNC – Used in radio, video, and test equipment.

- TNC – Ideal for wireless and RF applications.

- F-Type – Common in cable TV and satellite systems.

- UHF – Suitable for amateur radio and low-frequency applications.

- SMA – Used in cellular and GPS applications.

- QMA – Quick-locking alternative to SMA.

- FME – Designed for mobile communication setups.

- MC/MCX/MMCX: MCX connectors are for TV tuner cards for PCs, Wi-Fi routers, antennas, GPS systems, and cellular applications. MMCX connectors connect computer tuners to Wi-Fi and GPS.

- DIN/MINI-DIN: Single-line coax connectors are available in different varieties.

Choosing the correct connector type is essential for maintaining a secure, interference-free connection. While selecting a coaxial cable connector, you need to consider the key features of the cable you have to connect:

- The operation voltage: As the connector size increases, its power handling capacity increases.

- The required frequency: RF connectors have groups of families and series, and every series can operate in a particular frequency range.

- Corresponding impedance: Connectors must match the impedance of the cables.

- Coaxial connector gender: All the RF connectors either have plugs or jacks. Plugs, having thread inside, are males, while jacks, having threads outside, are females. However, not all RF connectors are threaded. There are MCX connectors that use a snap-on mating process.

- Form factor: Coax connectors have been getting smaller since their development. Nowadays, you can get a micro-miniature IPX connector as small as 2.5mm. However, remember that size affects the power handling capacity of the connector.

- Durability: Several factors affect the ruggedness of RF connectors, such as their coupling style, mating cycles, outdoor or indoor use, and operating temperatures. Most RF connectors have a rating of 500 mating cycles. Mil-spec RF connectors undergo testing under high vibration and corrosion-stimulating conditions.

- Insertion loss: Factors such as coax cable length and type affect insertion loss, which an RF connector must constantly work to reduce.

Custom Coaxial Cable Types at Wiringo

At Wiringo, you can customize your coaxial cable assemblies to fit any application. We offer cables that can withstand any challenging environment, including RG braided cables, micro coax, semi-rigid cables, LMR types, and hand-conformed cables.

Connectors for Radio Frequency cable assemblies are available in many sizes and types, either a male or female connector with a straight or right angle, bulkhead, or other options. The connector types available are 1.85mm, 1.0mm, 2.92mm, 10-32, 2.4mm, 7/16 DIN, 4.1/9.5 Mini DIN, Mini SMP, BNC, F, MCX, MMCX, Mini UHF, N, RCA, QMA, SMB, SMA, SMP, SMC, SSMB, SSMA, UHF, SSMC, U.FL, TNC, and UMCX.

Contact us today to find the perfect solution for your project.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.