About Conductor Testing, In cable testing, you can check the tensile strength and the corrosion of copper. Further, you can also test the thickness of insulation and break of insulation. However, appropriate conductor resistance is the most essential for the efficient working of electrical equipment. Thus, the conductor test is necessary for cable testing.

Image: fiber optic cable testing

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Why you Must do Cable Testing

Crushing, breaking, and bending are some common cable faults that you see every day. And these cable faults affect the electrical performance of the equipment. However, if you detect them early, you can avoid major problems later.

Testing helps to check the electrical performance of a circuit. You can check cable quality and cable conformity with this. Further, you can also test cable functionality.

Cable testing is a complex task. Experts use various cable test techniques to ensure smooth and continuous cable connections. Some of them are insulation resistance measurement, dielectric strength measurement, continuity measurement, conductor resistance testing, and many more.

Here, we will discuss the conductor resistance testing in detail.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

What is Conductor Resistance Testing?

It checks if the quality of the cable conductor is good. You can do this on the complete cable length. Or you can take a cable length of 1m based on IEC60228. With this, you can test the direct current resistance of copper or aluminum conductors. High resistance means that the current flow is low. This indicates possible cable faults.

Conductor resistance is expressed as ohms per km. There are two tests for cable conductor testing. These are the Kelvin Double Bridge test which gives an accuracy of 0.2%, and the Wheatstone bridge test with 0.5% accuracy.

Factors Affecting Conductor Resistance

Why is there a need for conductor resistance testing for cables and wires? Well, it is because some factors change the conductor resistance. These are:

Length:

The resistance of a conductor is directly related to its length. Let’s understand this with an example. Suppose you take two wires of different lengths. Now, you give the same voltage to their ends. The longer wire will have less voltage per cm. As a result, the electric slope or the potential gradient that moves electrons is less steep. This decreases the velocity of moving electrons. So, with the longer length, the current decreases, and the resistance increases.

Cross-sectional area:

The more the diameter, the more electrons pass through a definite point. More electrons moving means more current flowing. And more current means less resistance. Thus, resistance is inversely related to the cross-sectional area.

Nature of material:

It’s the electrons that carry current. So, the flow of current largely depends on the availability of free electrons. Some atoms have more free electrons in their outer shell. As a result, the material will have ample free electrons. Thus, it will be a good conductor with loss resistance. On the other hand, if the outer shell is full, the atom will not allow its electrons to move. Thus, the material will have more resistance. For example, copper has four electron shells with one electron in the outer shell. On the other hand, Silicone has four shells with four electrons in its outer shell. Thus, copper is one of the best conductors, and silicone is the best insulator.

Image: copper wire

Temperature: When the temperature increases, it leads to more vibration in the atomic lattice. The vibration in the lattice causes more hindrance in the movement of electrons. As a result, the resistance increases, and current flow decreases. Thus, conductor temperature measurements are an important part of cable testing.

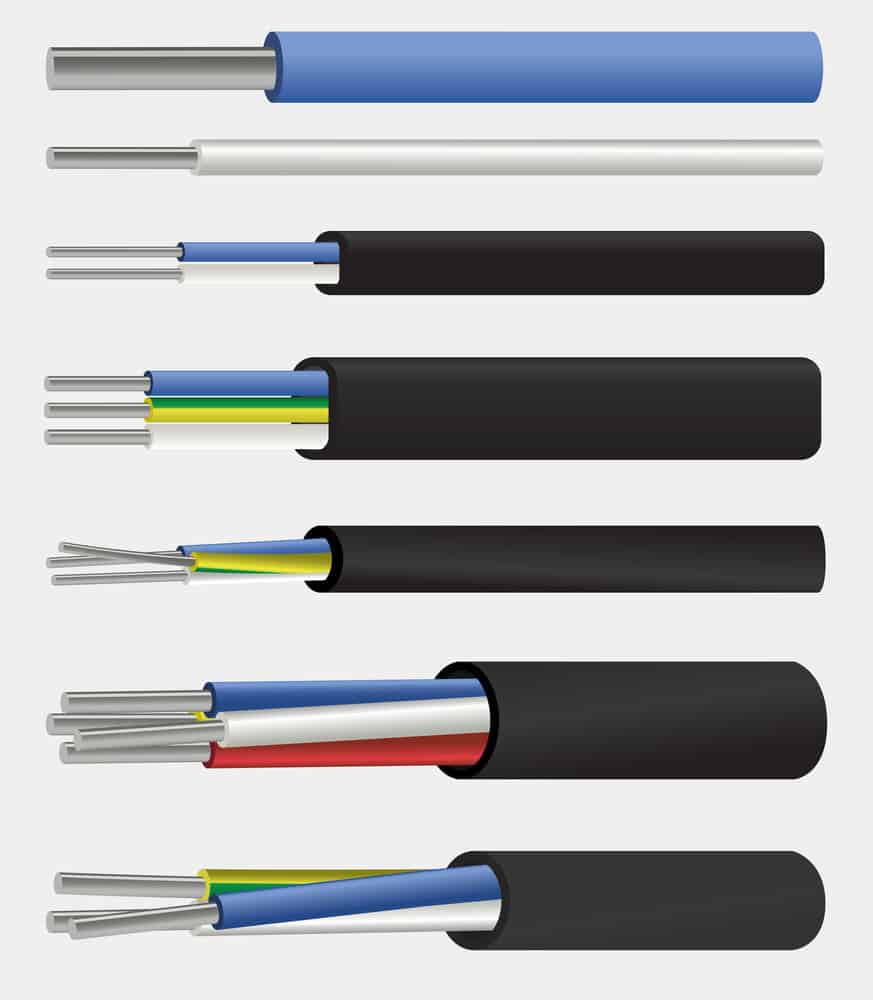

Image: electric aluminum cable

Conductor resistance testing

Traditional cable test techniques use the difference in voltage across known resistors to know the unknown resistance. Alternatively, modern equipment calculates cable conductor resistance based on ohm’s law. In this, you calculate current and voltage across a sample. With this, you can calculate resistance.

Things to know before conductor resistance testing:

This method can calculate the direct current resistance of class 1, 2, 5, and 6 type conductors. For the test, conductors can be Aluminium, its alloy, plain copper, metal-coated copper. The specimen used in this cable testing must have a cross-sectional area between 0.5mm2 to 2500mm2. You will get results in ohms/km.

As temperature affects resistance, keep the test sample in the test area for a sufficient measurement time. This stabilizes the conductor temperature. This allows accurate measurement. According to BS EN 60228, for accuracy of performance, the conductor temperature should be 20oC.

Conductor resistance testing procedure:

First, you need to collect the test sample. You can take any solid conductor having a drum length of 1m. Or take any solid conductor up to a size of 25mm2. The drum length should be 5m. You can also take sector solid conductors with a size greater than 25mm2. The drum length should be 10m. Length here refers to the length between the voltage terminals.

Then perform the test:

- First, connect the test specimen to the bridge that measures resistance.

- Secondly, check all the considerations related to contact resistance before the test

- Thirdly, calculate the resistance

- Finally, note down conductor measurements

Now, convert the measured resistance into equivalent resistance at standard temperature (20 degrees celsius) and length.

Conductor Resistance Testing Calculation:

You can calculate the measured resistance with the following formula

R=((Rt*k)/L) *1000ohms/km

Here,

Rt=Observed Resistance

K=Temperature correction factor

L = Length of specimen in m.

Your conductor resistance must meet standard resistance readings. For this, compare observed resistance with conductor resistance at 20oC. Use this formula for comparing.

R20 > (Rt*kt*1000)/L ohms/km

If your observed resistance is more than R20, you may have some conductor issues. However, before that, check for the following whether

- Conductor temperature is less than 20oC

- Cable length is correct, as the longer cable will give higher resistance.

- Your conductor is pure

- Your conductor has sufficient quantity

Result

Based on the results, you can say whether the sample meets or does not meet your requirements.

Conclusion

A high resistance results in the heating effect. It can result in a fire or a short circuit that can be life-threatening. But don’t worry. Good quality cables can minimize resistance issues. If you need any help in this regard, contact Cloom. We deal in high-quality wires and cable assemblies. We can cater to all your cable testing needs.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.