When designing a project, don’t think of the wire or cable harness as a bunch of wires. Be careful not to focus all your attention on the design’s function, form, and features, and leave the wiring for the last steps. Doing so could later result in some complications, especially if your project primarily involves consumer appliances and the electronics industry. Now let’s discuss your choices when designing a consumer cable assembly.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

What is Consumer Electronics?

Home or consumer electronics refers to any analog or digital devices used daily in private homes, including communication, recreation, and entertainment equipment. It is often referred to as black goods because they mainly come in darker colors. In comparison, devices used for housekeeping and cleaning, such as fridges and washing machines, are referred to as white goods because they generally come in light colors. However, today the line between white and black is somewhat blurry. In the British English Community, sellers and producers refer to some products as brown goods. Most large consumer electronics stores that sold white and black goods in the past had no distinctions.

In the early 20th century, radio broadcasting introduced the broadcast receiver, the first major consumer product. Later other products were developed, such as TVs, calculators, telephones, video recorders, mobile phones, gaming consoles, MP3 players, and personal computers. In the 2010s, more consumer electronics were developed, such as car stereos, GPS, electronic music instruments, video game consoles, video players, digital cameras, and karaoke machines. Stores began selling smartphones, cellphones, small light fixtures, camcorders, and digital cameras. Some newer consumer products include smart home devices and VR head-mounted devices. Over time consumer products began merging with digital technologies and began increasingly called the consumerization of information technology. Today consumer electronic stores also sell baby and office furniture. Furthermore, the stores have expanded combinations of both physical and online stores.

Household appliances

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Consumer Cable Assembly Understanding

Manufacturers designed wiring harnesses for use in various electronic products and home appliances. These electronic and home items are key in exchanging signals or data and supplying power. When used in mobile phones, PCs, TVs, gaming instruments, or digital cameras, professionals refer to a wire harness as a consumer-use wiring harness.

Serial DMI

How to Design Consumer Appliance Wire Harness

Here are some key points to consider when designing your wire harness:

- Every component of the harness could affect the finished product.

- To serve specific environmental conditions, you must design coverings, wires, and connectors.

- Always consider operating temperature, voltage, and amperage when making decisions.

Wire Harness Assembly

- The length of the wire does not necessarily determine its price because assembly time has a heavier impact on the cost should you make a mistake.

- A common mistake people make is during the routing and bunching of wires. Ensure you lay out the wires clearly to avoid making mistakes.

- Because of the large potential of terminations, ensure the design is simple to avoid placing terminals in the wrong place.

Wire Harness installation

- Here, the wire and heat-resistant connectors’ costs are lower than the cable installation. Therefore, ensure to keep that in mind while making decisions.

- Although spinal cord designs have more wires than spider web designs, they are easier to install and service.

The Connectors

- Your connector choice depends entirely on the speed and type of signal you plan to transmit.

- If you plan on sending power through, opt for a crimp-type connector.

- Also, choose a welded or soldered connection if you intend for it to transmit a high-speed signal.

- Keep in mind the final assembly has a specific connector. Therefore, you have limited terminal choices.

The Conductor or Circuits

- The number and type of conductors or circuits depend on your application.

- Copper is often the preferred conductor material because it is compatible with various coatings slowing the corrosion rate.

- You could use copper alloys or copper-clad steel if you need more breaking strength.

The Coverings

The wire covering offers an extra layer of protection and insulation against fluids, chemicals, abrasion, heat, vibration, moving parts, rattles, moisture, and rattles. Also, flexible wire coverings protect against EMI.

Some wire coverings include:

- Cable protection sleeve: Wrap or expandable sleeving is easy to install and highly flexible, enabling quicker wire bundling. Often, braided sleeves use PET because of their lightweight design, durability, and flexibility, even under low temperatures.

- Tape: You can find pressure-sensitive single-coated tapes in many backing materials and adhesives. You can use PVC as the backing material. However, some tapes use felt, foil, cloth, or foam. With tapes, stiffness is often an issue because it minimizes flexibility.

- Heat shrinking tubing: This tubing wraps around wires, smoothing the surface and providing electrical and thermal insulation. Also, adhesive-backed tubing serves as a seal against chemicals and moisture.

- Split loom tubing: This has a slit on the sides of the covering for easier wire insertion. After installation, you must seal the slit to eliminate the need to heat shrink or spot tape. There are several materials, with the common choices being split wire mesh loom and steel braided wire loom.

- Spiral wrap tubing: It allows wires to exit and enter the covering at multiple points. Professionals often use polyethylene and polyamide, available in various colors for easier identification.

Environmental Considerations

When designing a wire harness, it’s important to consider every aspect of the design, particularly the environment you’ll expose it to. Consider the following:

- Can every component withstand the required operating temperature and voltage?

- Are the harness mounting and connector designed to relieve pressure from extreme vibrations?

- Does your harness need to contend with moisture, detergents, or grease?

- Is flammability a concern?

The Safety Standard

Safety is vital when designing a wire harness. Therefore, ensure your design complies with the necessary standards, keeping in mind that every country likely has different federal standards enforcing the testing and certification of electrical devices. Most countries use the following guidelines as the backbone of their standards.

- International Electrotechnical Commission

- European Committee for Electrical Standardization

- International Commission for Rules for the Approval of Electrical Equipment

The IPC/WHMA-A-620 Standard Revision C is the only industry standard for Requirements and Acceptance of Cable and Wire Harness Assemblies. And the WHMA and IPC are continually working on developing helpful updates.

The Environmental Standard

You should be familiar with the three standards limiting the use of hazardous substances:

The WEEE Directive governs the disposal and recycling of electrical products once they’re no longer usable.

In addition, concerning the safety and federal environmental standards, assemblies may have to meet standards based on specific performance criteria. Also, depending on your intended application, you may have to meet additional standards and certain criteria, such as QSFP, HDMI, or independent testing services such as ETL.

Different types of Consumer Appliance Wire Harness

Consumer Electronics Connector Products

Some examples of consumer electronic connector products include:

868 Series spring-loaded and target connectors of Military Max Mfg. Corp.

This product features a sturdy solder cup termination accommodating the cable and wire attachment as it also handles the insulated flanges and securing options to accommodate further application stability.

The connectors are soldered and come in a pitch of about 4mm, with the pins uniformly aligned to efficiently facilitate soldering various wires of up to 16 AWG. Professionals use these connectors for mounting inside component housing for cable terminations, robust quick connections, and docking stations.

Also, the connectors have robust pins with diameter plungers of about 1.27mm, capable of resisting binding and bending while applying side loads. Further, the connectors feature a stainless steel gold-plated spring delivering reliable operation during countless cycles. That’s because the gold-plated spring is less likely to undergo stress relaxation while operating overtime under extremely high temperatures than other options available.

Every spring pin has a 9A rating with a 10°C increase while providing a cable stroke of about 2.29mm and contact resistance (lower than 20mΩ). With mating intended connectors, you can choose between a concave or flat face for the pin’s mating side.

The Mill-Max Mfg. Corp’s 868 Series is also equipped with nylon 46 high-temperature molded insulators compatible with joined mounting tabs, enabling secure attachment of the product to PCBs or the finished product housing. In addition, brass components provide corrosion resistance, durability, and high conductivity.

Solid signal double lock connectors of TE Connectivity:

With cap and plug housing, you can get wire-to-board and wire-to-wire single-row configurations. Also featuring 2-10 wire-to-wire or 2-13 wire-to-board crimp contacts with a pitch of about 2.5mm.

Professionals usually use these connectors in signal circuits for household appliances and consumer products. The connector features two internal lock plates, ensuring correct mating and a neat appearance. It also has polarizing ribs on the plug housing, polarization pegs, soldered tail kinks to enhance board retention while soldering, and audible mating confirmation.

The TE connectors are compatible with 20-26 AWG wires with an insulation diameter of about 1.8mm. They’re also available in various colors, all UL-recognized, TUV-approved, and CSA-certified. You can get mounted board headers in either standard or special versions compatible with conformal coatings and resin. However, you could opt for the radial tape-mounted model for radial mounting machine applications.

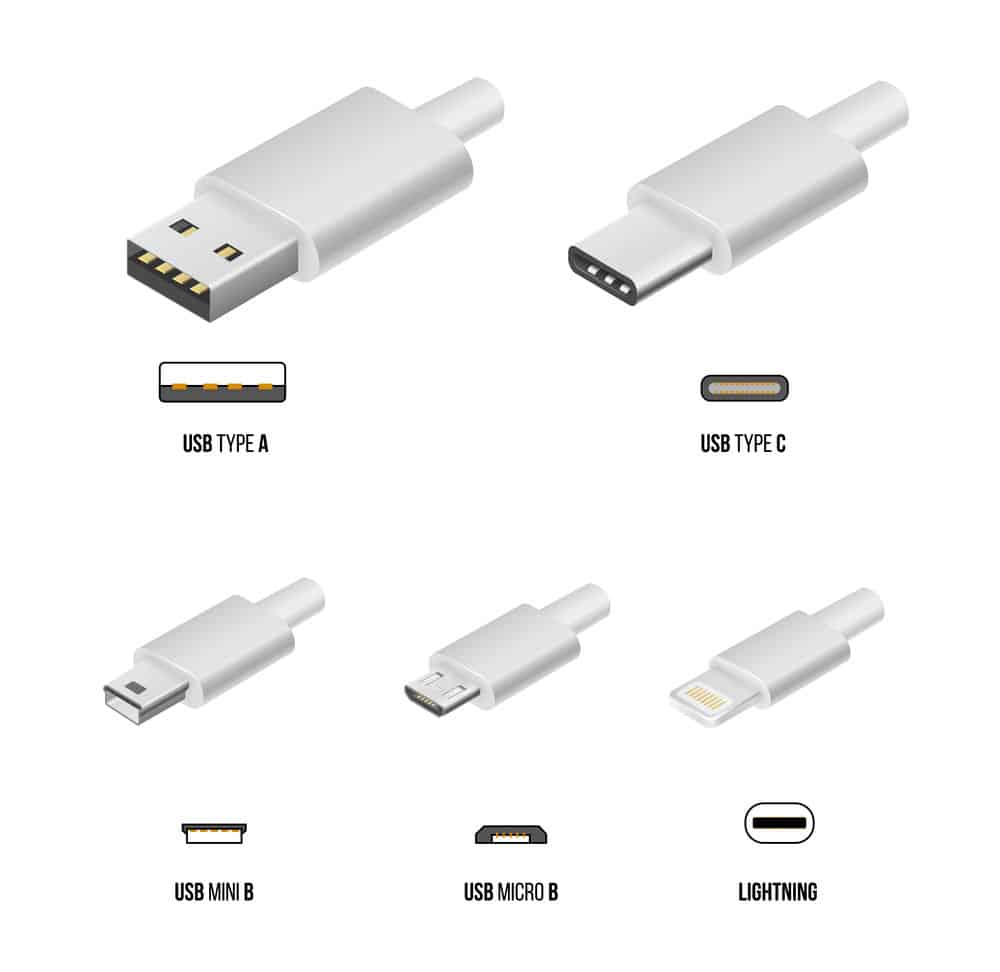

USB type-C waterproof connectors of Amphenol ICC:

Its primary capability is delivering up to 10Gbps, facilitating super fast communication while supporting USB 3.1 Gen 2 and 1 protocols, and backward compatibility with USB 2.0.

Caption: Type-C cable connector

This connector is almost equal to the micro USB cable connectors but has a lower profile casing with cable orientation and reversible plug for a better user experience. It’s ideally used in datacom, consumer, telecom, medical, automotive, and industrial applications. However, it’s also applicable in mobile phones, flash drives, tablets, hard drives, virtual reality setups, high-temperature drives, point sale systems, industrial computers, infotainment systems, and car charging outlets.

Caption: Micro USB cable

The Amphenol ICC’s waterproof USB type-C connector also features terminals of quality copper alloys. Also, the front-end insert molds for IPX2 to IXP8 in a right angle standoff, 24-pin assignment to enable compatibility with various video and audio signal product protocols, O-rings, straddle mounted configurations with a rating of about 10,000 cycles, and waterproof glue.

Alloy 174 military-hardened copper-beryllium alloy striped material of Materion:

Professionals usually use these connectors in high-density, miniaturized, telecom, automotive, medical, aerospace, and datacom. You can also use them for terminals, connectors, and contact springs for relays and switches. Their design enables them to recover the cost and performance differential among the lower-performing copper alloys, for example, beryllium copper and brass.

Further, manufacturers designed Alloy 174 to facilitate conveying high current facing low-temperature increase while exhibiting stress relaxation resistance at extremely high temperatures. In addition, a higher electrical conductivity than most copper alloys, increased thermal conductivity, formability-to-strength ratio, predictable, regular forces, and impressive reliability.

The Alloy 174 can withstand stress with strengths of about 125 ksi, which is far better than other strip alloys such as silicon bronze, brass, phosphorous bronze, and alloys of copper-nickel and aluminum. Also, it offers longer thermal stability and higher spring force maintenance while easily conforming into any shape, enabling withdrawal forces, low insertion, and extremely unvaried cycle lives.

Upon exposing the Alloy 174 to stress, for example, the strength of up to 45 ksi during the intense reverse bending process, its cycle life will still maintain countless operations. The material used in Alloy 174 offers stain retardant treatment providing temporary protection from surface link growth, such as oxides in industrial areas with higher humidity rates.

You can get the material in solder coating, rare metal inlays, and tin plating. Rest assured that it’s compliant with UNS C17410, ASTM B 768, and AST B 888 standards, enabling simpler integration alongside various specifications and existing projects.

JF08 Series internal high-speed harness assemblies of JAE:

They comprise flat flexible cables compatible with fast differential signals primarily applied when interfacing with camera modules, OLED/LCDs, and a variety of daughter boards. These boards include PCI-E, USB cables, LVDs, single row 51 or 41-point plug connectors, adaptive locking latches for proper mating with the FI-R Series outlet connectors, and large guideposts for easy alignment.

Caption: USB cable types

Professionals use these connectors to design consumer electronics, such as servers, PCs, monitors, TVs, speakers, printers, gaming systems, and several communication devices. Assemblies come in standardized lengths of 40cm, 30cm, and 20cm, capable of folding to meet various cable design routing specifications in space-constrained uses. Each contact has a 0.3A rating, with the highest contact resistance being about 30mΩ, minimum insulation of 100mΩ, and dielectric withstanding voltage of 250 VAC/rms. In addition, it can operate at temperatures ranging between -30°C and +80°C. These connectors are also RoHS-compliant and provide accurate impedance matching.

Schleuniger’s RotaryStrip 2400

It features high precision, flexible, and fully programmable stripping machine with the ability to process 10-36 AWG solid or single and multi-conductor cables or stranded wire made of various insulation materials such as Teflon, Kaptin, and fiberglass that don’t require mechanical adjustments.

You can also use the Schleuniger connector to twist and strip a range of wire sizes from 13-26 AWG while still performing any forms of stripping from the multi-step, full strip, and partial strip. Furthermore, the machine has a state-of-the-art touchscreen interface, allowing users to quickly input and keep records of a couple of programmable processing variables, such as feed rate, pull of speed, and stripping diameter and length. That allows for broad use stability while providing users with a full picture of the working space.

TE Connectivity’s USB type-C cables and waterproof connectors of Heilind:

They provide power, video, and audio connectivity, increased EMI protection, and data. In addition, IPX4 splashproof or IPX8 waterproof protection for industrial, consumer, automotive, medical, telecom, and datacom applications.

Professionals also use the Heilind connectors in tablets, smartphones, wearables, power packs, laptops, chargers, data centers, lighting systems, infotainment systems, and factory automation equipment. At 5A or 20V, connectors can transmit power of up to 100W and 10Gbps while maintaining a strong housing equipped with a changeable mating interface and increased board retention capabilities. Also, a solid dual-row surface mounts technology footprint while supporting various protocols such as USB cables 2.0 and USB 3.1 Gen 2 or 1. Moreover, the machine utilizes converter cables or adapters such as VGA, DisplayPort, HDMI, and various other connections.

Caption: Cable connection types

ACES 50696-XXXXX Series Connectors:

ACES Connectors’ surface-mount technology (SMT), flexible printed circuit (FPC), zero-insertion-force (ZIF) connectors comprise 19 standard circuit options with 4–30 high-performance phosphor bronze contacts, back flip actuator, 0.5mm pitch, and a low height profile of 1.06mm.

You can use these connectors with reflow and hand soldering processes and with high-temperature thermoplastic or only thermoplastic and actuator materials. The connectors can also support the fast transfer of USB 3.0 data and feature a fitting copper alloy nail and accepting cable up to 0.3mm thick.

The series has a maximum of 60mΩ contact resistance, 0.5 per pin rating, 20-cycle durability, and 200 VAC/rms dielectric resistance voltage. Also, it can operate under temperatures ranging between -400C to +850C and the lowest insulation resistance of 500MΩ.

Cat 6A Z-MAX 6A shielded outlets of Siemon Interconnect Solutions:

They utilize remarkable Cat6A performance and exceptional termination time, surpassing the necessary industry standards. They’re crucial to the end-to-end Z-MAX 6A shielding cable systems.

These outlets consist of various components, each performing a specific duty. Strong die-cast housing performs the following duties:

- Strong die-cast providing optimized shielding against alien crosstalk and EMI.

- Diagonally positioned IDC contact layout increases separation of pair-to-pair, decreasing alien crosstalk even in the most concentrated Cat 6A patch environment.

- Zero cross-level termination elements enable acceleration of lacing while eliminating crossed pairs and splits.

- You can opt for a door that has been spring-loaded and is capable of reducing exposure to contaminants and dust, enabling easy single-finger use.

- A pass-through technology that allows rear or front faceplate mounting.

- The hybrid design allows mounting outlets of the same type in angled or flat orientations.

- Integrated coupled metal clip relieves cable strain and quick shield connections.

Also, Simeon’s products have patented jack-crowned contact geometry that enhances mechanical and electrical performance.

Thanks to the Z-Too, you can perform quick terminations, enabling fast and coupling with low force. Additionally, you can get shielded outlets in various colors, with several accessories and colored icons to enable easier port identification, all of which are by several industry standards and ETL tested.

Conclusion:

With the consumer electronics industry constantly undergoing innovations, it’s important to stay updated. Fortunately, Wiringo offers customized electronic wiring harness solutions to meet ever-changing requirements. We have a variety of premium wire harnesses and cable assemblies built from high-quality materials, available in a wide range of dimensions and colors to meet your specific federal standards. Contact us for the best custom wire harness and complex cable assembly services.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.