Custom wire harness and cable assembly stay the least discussed most essential ingredients of projects yet. Overlooking the importance of custom cables and wiring harnesses may cost you substantial repairing costs beyond your imagination. What if a typical low-quality wire ends up causing short circuits that result in havoc?

Electric cable assemblies for industries

CLOOM Tech proudly presents custom cables assemblies and wiring harnesses for all industrial projects. From aesthetics to the safety of the appliance, custom services are simply the only solutions. There is a lot more to know for you, and here are some facts that every project team must be aware of:

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

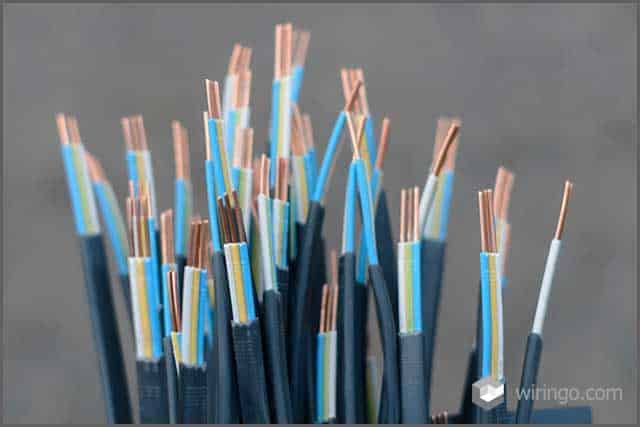

1. Cables And Wires May Look Identical But Are Not The Same.

If you are dealing with both terms, in the same manner, you are already a step closer to risking your project. Every professional must be aware of the applications of wires and cables. Although both electric equipment serves almost the same purpose yet are not interchangeable. The error about the selection of the right electricity career defines the safety of your project.

Bare stranded wires

At CLOOM Tech, we deal with many cases where teams don’t choose the best option for their appliance. Our professionals and engineers analyze the project and work environment to suggest the right choice. Both options are suitable for carrying signals and current, but their applications are different depending upon many factors. A standard wire generally features some strands of some conductive material like copper. In simple specifications where simple current flow is the goal, wires can be a good choice.

Cables consist of more two or more conductive materials with an external protective layer for safety purposes. Industrial electricity transmission requirements are different from residential settings. Hence, you need to look for more durable options to carry current, and custom cable assemblies are the correct options available.

2. Military Installations Use Custom Wiring Harnesses And Cable Assemblies

You may be surprised to know, but the use of custom cable assemblies is not limited to commercial and industrial settings only. These custom products are useable in any environment where you need precision and durability. Durability is the priority in military installations, and standard cables and wires cannot stand a chance. Current supply lines have to take rigorous abuse in high-temperature areas, and at that point, custom assemblies stand firm.

There are some essential factors in military installations like precise, uninterrupted, and compact power supply management that require custom products. Aerospace manufacturing units are also dependent on custom cable assemblies.

Custom cables for military installations

Modern planes and war crafts have sleek designs, and weight reduction is essential. General wiring for current and data supply adds a lot to the aircraft’s weight and takes up a lot of space. Cable assemblies provide better cable management in aircraft and other ground military installations. Tactical cables and other custom cable assemblies with additional protective layers are in demand in the aerospace market. In the data transmission for military communications, authorities look for custom cables that can prevent external interference. Hence, the use of custom cable assemblies and wiring harnesses for military appliances and installations will boom in the next few years.

3. Cable Assemblies Can Perform In Saltwater Too

Do you think that standard market cables are suitable for marine projects where exposure to water is inevitable? Market cables not only create limitations in terms of length, but these cables also cannot stand against saltwater. The insulation of standard cables will start cracking in no time underwater. So, these projects need custom cable assemblies, and wiring harnesses with resistive materials against water. We have waterproof cable assemblies for oil refineries and extraction units working in the sea, and these cable assemblies have unique protective material that remains unaffected even underwater.

If you think you can get things done with standard market cables, you need to calculate the risk. The first risk is the maintenance cost assessment. Underwater maintenance of the power cables is going to take a lot of workforces and cost too. Even if the wires are not underwater, continued water exposure is apparent. Wet lines not only start cracking sooner but pose severe threats to human life too. Due to limited access to the land, the maintenance procedure will affect the production capacity too. All your units will be on halt for a long time. Hence, the use of custom cable assemblies allows the teams to avoid these unwanted threats and interruptions.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

4. Custom Wire Harness And Cable Assembly Are Shock Resistant

Heavy machinery units involve a lot of appliances working together, and these industrial work setting environments affect a lot of vibration and movement. Standard market cables don’t stand a chance against such extreme use, and custom cable assemblies are the only option left for work environments where many mechanical vibrations create problems.

Realistic isolated electrical wires

CLOOM Tech is one of the top custom cable assemblies and wiring harnesses manufacturers, so we have solved the teardown of cables due to mechanical vibrations. We use flexible yet durable materials as the external protective layer for the custom wiring harnesses and cable assemblies. These additional protective coatings resist the possible movements without compromising the power supplies. If you think that tight cable fixtures will solve the tear due to vibrations, you will break the wires even earlier. When cables are too close, a slight mechanical path movement will break the wires and cables. Why would you ever risk safety when you can have better performance with custom cable assemblies?

5. Custom Wire Harness And Cable Assembly Can Cut The Maintenance Costs

Maintenance is a nightmare for engineers. These processes are not only time taking but can cost you a fortune too for mega projects. Every small wire and connector in an appliance matters a lot for the smooth working of the project. General Cable arrangement can take a lot of space, and when it comes to diagnosing, technicians will face many issues while reaching the suitable cable. Some industrial settings can include thousands of wires. Just imagine that power went down, and now you will have to detect the issue. It will take days to find the faulty cable.

Electrician engineer works with electric cable wires.

In such scenarios, custom cable assemblies prove to be an excellent investment. Cable management will custom cable assemblies, and wiring harnesses are way better and optimized than the market cables. Not only is the cable management better, but the durability is outstanding. Due to better protective materials, the chances of tearing and cracking are rare. Hence, in the long term, investing in custom cable assemblies and wiring harnesses can save you high maintenance costs.

6. Oil And Gas Industries Use Custom Wire Harness And Cable Assembly Only

Chemicals and lubricants are the biggest enemies of cables and wires. In residential and commercial applications and work environments, chemical exposure is almost negligible. Meanwhile, in industrial projects, chemical exposure is one of the significant drivers for custom cable assemblies and wiring harnesses. Oil refineries and industrial projects use a lot of heavy machines. Lubricants are essential for the smooth performance of the parts, but these lubricants can be destructive for the cables.

Oil refineries and petroleum units

In oil refineries, engineers use different chemicals for the cleanup process of crude products. No matter how much you try, there will be some chemical spills that might damage the wires. So, refineries and other industries have to use custom cables assemblies no matter what.

7. Custom Wire Harness And Cable Assembly Can Be More Affordable Options

Cost assessment has a significant impact on the choice of custom cable assemblies over market cables. Do you think that custom cable assemblies and wiring harnesses are more expensive than typical cables? Well, you may be suitable if you compare our production with cheap lines. CLOOM Tech has quality standards that stay intact no matter what. So, we have managed to offer the same price as market cables due to our in-house labs and production units.

When combined with maintenance costs, labor costs, and wastage of cables for typical cables, custom products offer more affordable options. We are the best in terms of quality and durability, but we are unbeatable in terms of pricing. We provide cheap custom cable assemblies and wiring harnesses.

Conclusion

A basic understanding of the facts and applications of custom cable assemblies and wiring harnesses can lead to better performance of projects. If you are looking for the best custom wiring harnesses and custom cable assembly manufacture, CLOOM Tech can deliver beyond your expectations.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.