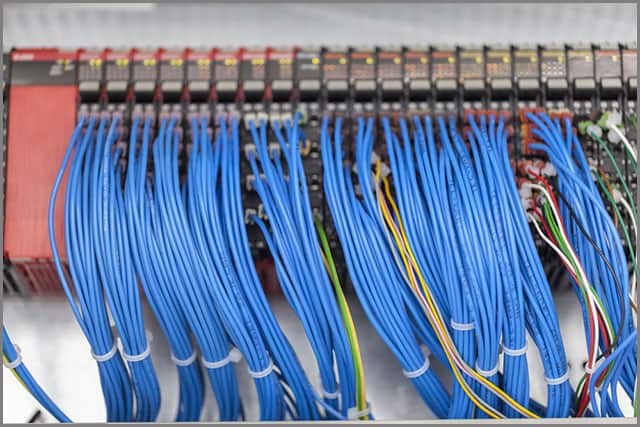

A wire harness is imperative to equipment as it carries power and signal through it. A custom wire harness helps in connecting various components of a device. Otherwise, they will become useless.

A collection of several wires packed in a bundle is a wire harness. These wires are put together with a band, sleeve, tape, or lacing as it stops them from branching out. The wire harnesses carry electrical and power signals through them.

They help components of an equipment function properly. It’s the basis of functionality for all the equipment involved in aircraft, computers, audio systems, and so on. If a wire harness doesn’t connect the power source to the equipment component, it will fail to work.

This article will inform you about the key factors that you must keep in mind while buying a custom wire harness. It’ll help you pick out the right supplier/ distributor/ manufacturer to mass-produce your custom wire harnesses.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Step 1: Consider the cost-effectiveness of your custom wire harness

You might have an urgent project that requires urgent custom harnesses. The first thing you need to consider when placing the order of a wire harness is the cost and the quality of the product. You can either get low-quality products that are cheap or invest in high-quality, competitive products.

Low-quality products are not durable because they require constant maintenance and repair. Therefore, they’d prove to be expensive in the long run. You might also get a wire harness that uses expensive material but doesn’t suit your requirements at all. You must keep your requirements in mind while making a choice.

Here’s how you can understand the costs and make the right choice with your custom wire harness.

Time Costs:

The quality of the product can determine how much your company will end up spending on the custom wire harness. A poor-quality wire harness can affect the operation of your equipment. Not only will they make the machinery inefficient, but they will also affect the implementation of it. Cheap and inferior quality products cause unnecessary trouble as they require a lot of maintenance. Hence, they end up costing more than the actual price of the wire harness.

Money Costs:

Even the smallest of the harnesses are important to any project. A wire harness, despite its size, helps in the functioning of any equipment. Inexpensive products are generally low in quality. If your wire harness is too cheap to believe, the chances are that it isn’t well made. For example, the terminal and the line number of the wire harness might not match.

It’s also possible that the tensile test of the harness is not closed. Even if they work properly, low-quality harnesses aren’t durable as they don’t meet the industry standards. So, you may end up repurchasing the cable and spending double the amount of money you already have. Therefore, low-quality and cheap products always end up being more expensive than a good-quality product.

Finding a reliable manufacturer or supplier of custom wire harnesses is of utmost importance. They understand that efficient companies don’t delve into time-consuming and laborious things. This way, you always get your product well tested and in due time.

Step 2: Consider the hard power of the Wire Harness Supplier.

Look at the supplier’s equipment

Industries like automobiles, aerospace, military, electronics, and more make use of the wire harnesses. Wire harnesses take less time to install since you don’t have to deal with single wires. The absence of any loose wires also reduces any chances of malfunctions and short circuits. Wire harnesses can withstand heat, abrasion, and chemicals and are thus, quite durable. They can also improve the performance of the equipment.

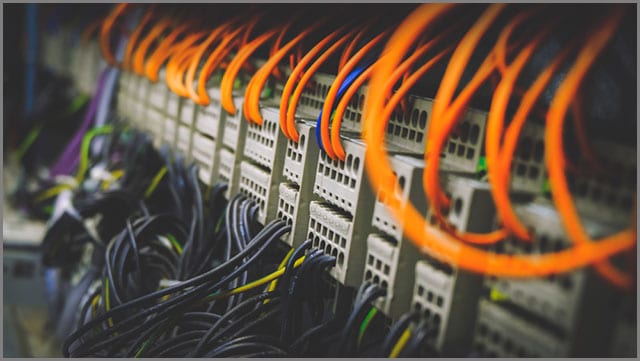

Your custom wire harness is only as good as the supplier who makes them. You should, therefore, always have a look at the kind of machinery and equipment they have. If their equipment is not up to date, they won’t produce wire harnesses that meet the highest of industry standards. Old technology also means the inability to produce a more diverse range of products. So, if your requirement is unique and demands a different kind of wire harness, you should pick a supplier who’d be able to design them all.

. Qualification confirmation for wire harness suppliers

The wire harnesses that you use in your company must meet the quality standards of the industry. It means that the suppliers that you choose to provide high-quality harnesses themselves. Every supplier must have the ISO 9001 certification for their organization. An ISO 9001 certification means that the company constantly provides products that meet the customer and regulatory requirements. So, if your supplier has an ISO 9001 certification, they’d produce high-quality wire harnesses that’d meet your project’s requirements.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Step 3: Talk to the wire harness supplier.

When designing a custom wire harness, you should always talk to the supplier first. Discuss your requirements and design with the suppliers and learn if they’d be able to provide you what you want. You should always notify the supplier of the environment in which you are using the harness. This way, they’d be able to decide the appropriate material for it. The amount of pressure that the harness would also decide the kind of components it’d have.

Here’s how you can discuss with your supplier and choose the right components for your wire harness.

Conductors

Copper is the best metal conductor around. But some wire harnesses might require a different material for a conductor as copper corrodes easily. The conductor should carry signals properly, and its carrying capacity shouldn’t exceed the voltage.

Terminals

A terminal is put at the end of the wire and connected to the assembly. The role of a wire harness depends on its terminal location and how it’ll be used.

Connector

Connectors join different wires together. Some connectors are permanently fixed into the system, while the others are removable and portable.

Strain Relief

Wire harnesses need to be flexible as they connect various components of the equipment. However, the place where the harness meets the component must be rigid. A strain relief provides the harness that rigidity to withstand the pressure at the connection point.

Grommets

Grommets keep the wires secure and in their right place. They keep the system organized and make installation and maintenance an easier job.

Insulation Jacket

An insulation jacket protects the wire from exterior conditions like water, heat, chemical leaks, and more. The appropriate insulation materials are PVC, rubber, and polyurethane thermoplastic.

You can mention these components while discussing the product with the supplier and see if they’re professional enough.

Step 4: Verify the supplier –Start with a small order.

Even after you’ve learned enough about the supplier and the quality of their work, don’t jump in with big orders. Start with a small sample list and less complex wire harnesses to test the quality of the product yourself. You’ll also get familiar with the speed at which the supplier produces the wire harnesses. You can repeat this process with other suppliers. When you confirm the quality and speed of the product, you can see which one produces the best product in the shortest time; you can order in bulk.

Another important factor in choosing the right supplier is their after-sales service, which many people tend to ignore. We’ll now learn why it’s an important factor.

Step 5: Excellent after-sales service

Even though you’re happy with the product that you’ve received, you can’t rule out any issues that might happen. There is always room for error caused by small omissions or problems due to the rigorous use of the product. The only people who’d be to handle the issues well are the supplier of the product.

The suppliers must take responsibility for their products. They must provide the required services even after the sale has happened.

Step 6: Why is our organization the best for custom wire harnesses

We’ve been a major supplier of electronic solutions for years. Our experience in manufacturing wire harnesses allows us to make a quality product in a small amount of time. We ensure to provide the best service for SMEs with our bulk harness manufacturing services.

Our team of professionals always follow-up after the delivery and tackles all the after-sales issues. The accounting department makes a reasonable quotation based on your product specifications and required quantity. Our procurement team purchases the required components from the biggest manufacturers. They ensure that the quality of the wire meets industry standards.

We have a team of professionals that tests every wire rigorously before sending it to the customer. If the wire doesn’t pass any test, it’s sent back to the factory for re-manufacturing. Our products and service speak for themselves and provide you the quality that you need at every stage.

We provide the following custom wire harness services.

Custom Wire Harness Manufacturing Capabilities

Have advanced machinery and equipment capable of producing a wire harness of any kind. We work with the specifications that you provide and design harnesses that meet the quality and industry standards. Test every product and make sure that they’re effective, especially those aimed at the military and healthcare industries.

Can design anything from the simplest point-to-point harness to the ones that require complex circuits. We also help technicians install the wiring harness to make sure everything’s perfect until the very end.

Flexible Custom Wire Harness Design Processes

Our team is ready to solve all your queries and issues regarding the design of the harness. We’ll work with your team, design, and create a prototype of your requirements. Thus, you can check the harness for fit, form, and function before placing an order.

You can increase the order as your business grows, and we’ll provide the products whenever they’re required. We also ensure a quick turnaround time for all our products.

Custom Wire Harness Quality & Performance Testing

Every product goes through a thorough quality and performance test to ensure its durability and functionality.

We test the harnesses by checking all of their wires, connectors, and splices. We also check the harnesses for durability by placing weights over various stress points. Polarization testing is done to ensure that they are safe and grounded. We perform visual testing of the product through the manufacturing process as well.

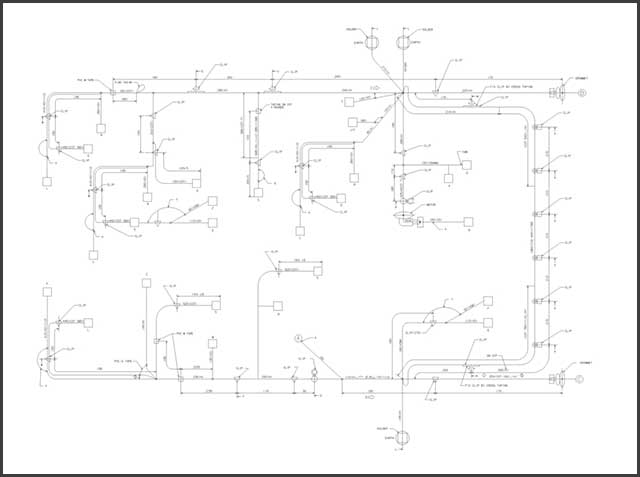

Contact Us for Turnkey Custom Wire Harness Solutions

You can meet our team with a wiring diagram, and we’ll help manufacture your wire harness. If you don’t have a design, our team will sit with you and help you out.

Our engineers and designers will understand all your requirements and structure design for you. We’ll then match it with your requirements and manufacture the harness for you.

Conclusion:

Building a strong relationship with a good supplier will drive more business for both of you and save your money as well. Therefore, finding the perfect supplier is always crucial to the project.

If you have any questions or are looking for a quality wire harness supplier, you can contact us.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.