Manufacturers of automobiles, airplanes, and machinery install dozens, hundreds, or even thousands of wires to connect components. If all these wires were loose, the risk of electrical problems would be high, and performing routine repair and maintenance would be difficult.

Whether you’re looking to restore a vehicle to its original factory specifications or build a custom street rod, kit car, truck, Jeep, or dune buggy, choosing the right engine wiring harness is important.

You can opt for OEM-style, factory-original custom harnesses or N.O.S. (new old stock) harnesses from aftermarket suppliers. Which option better suits your needs? Let’s find out.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

What Is an Engine Wiring Harness?

An engine wiring harness is made up of constricted wires, cables, terminals, and connectors controlling a vehicle’s electrical system. It relays electrical power and control information to components such as batteries, alternators, fuel injectors, fuses, audio systems, blower motors, fuel injectors, and computers.

Also known as a custom cable assembly, it is more than just a collection of multiple wires. The harness also reduces the likelihood of electrical problems that would otherwise affect the vehicle or equipment once fully assembled. Flame retardant over-molding minimizes the risk of electrical fires. Also, it shields cables and wires from moisture, thus preventing corrosion. In addition, installing the harness on the vehicle or machinery’s frame or chassis reduces the likelihood of damage from abrasions and vibration.

Major Harness Types

There are different types of vehicle wiring harnesses, including:

- Airbag – Controls the opening of the airbag in the vehicle.

- Main – Controls instruments, control panel, guidance system, multimedia, and electronic equipment. Forms part of the chassis wiring harness together with the front and rear harnesses.

- Engine – Manages the key functions around the engine including engine controller, oil controller gate, transmission plug housing, air pipe sensors, pressure sensors, and water temperature sensors.

- Body Wiring (or Body Harness or Floor Harness) – Keeps the air conditioning system, back sonar, navigation, dimmer switches, and speakers functioning.

- Battery – Delivers the main power to the other units. Serves as a connecting bridge between the engine and other vehicle components.

- Door – Found in car doors. It controls the door and window lock, door and window power, and the speaker.

- Roof – Located in the car’s roof and controls roof features, including the sunroof.

- Front Wiring – Forms part of the chassis harness together with the main and rear harnesses. Controls air conditioner fan, cooler fan, power sensor, temperature sensor, pedal sensor, speed limit sensor, oxygen sensor, and more.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

How to Choose an Engine Wiring Harness

You can buy an aftermarket harness or an OEM harness from a trusted manufacturer like Wiringo.

New Old Stock(N.O.S.)Harness from Aftermarket Suppliers

N.O.S. harnesses are exact replicas of the original wiring, offering a factory-accurate fit and performance. While they provide authenticity and reliability, they come with their own set of advantages and disadvantages.

| Pros | Cons |

| Straightforward Selection Process – Since these harnesses are designed as direct replacements, there is no need to worry about compatibility or matching components. The selection process is straightforward, saving time and reducing the risk of errors. Perfect Fit and Authenticity – These harnesses are exact replicas of the original factory wiring, ensuring a flawless fit and preserving the vehicle’s originality. Included Warranty – Most N.O.S. harnesses come with a one-year unlimited mileage warranty, often provided by the repair facility. This coverage guarantees peace of mind by ensuring the harness will perform as expected. | Potential Deterioration Issues – Even though these harnesses are new, years of storage can cause the wires to degrade or become brittle, potentially compromising their functionality. Limited Availability – Finding N.O.S. harnesses can be a challenge, as they are often only available through specialty suppliers or dealerships. The process can involve high markups, long ordering times, and limited stock. High Cost – Due to their rarity and exclusivity, N.O.S. harnesses are typically much more expensive than reproduction options. This can make them cost-prohibitive for budget-conscious projects. |

Factory-Original Custom Wiring Harnesses for OEM Design

Custom harnesses are designed to match or even improve the quality of OEM designs. They are a cost-effective and customizable alternative, but they have their strengths and limitations; like any option.

| Pros | Cons |

| Cost-Friendly – Custom harnesses are produced by a wide range of manufacturers, leading to competitive pricing and more accessible options. Customizability – Unlike N.O.S. harnesses, reproduction options can be tailored to specific needs. Manufacturers like Wiringo can create harnesses to fit unique configurations or accommodate aftermarket modifications, making them highly versatile. Equal or Better Quality – Many custom harnesses are reverse-engineered from original designs. Manufacturers often improve on the original specifications, offering increased durability, efficiency, or compatibility with modern upgrades. | Limited Warranties – Some custom harnesses come with minimal warranties or none to keep costs down. This lack of coverage can be a concern if unexpected issues arise after installation. Quality Variations – With thousands of manufacturers producing harnesses, quality can vary significantly. Some products may not meet high standards, requiring careful research and selection to avoid subpar components. Complex Selection Process: While the variety of options is a strength, it can also overwhelm the selection process. Ensuring compatibility with specific vehicle models or modifications may require knowing the part numbers, particularly for less common or highly customized builds. |

How to Troubleshoot an Engine Wiring Problem

The device served by the broken or damaged wire may stop working. So, you must diagnose it with the proper tools.

Identify Relevant Relay or Fuse Box

Use the fuse box guide or repair manual to identify the relay or fuse associated with the non-working component. If multiple accessories aren’t working, use the wiring diagram to locate shared contact points in the circuit. With that, you will narrow down the areas you need to inspect and test.

Inspect and Test the Fuse

Inspect and test the fuse to confirm it has not burned out and isn’t the cause of the problem. If you have a bad fuse, replace it with one that has the same amp rating.

Expose and Inspect Component and Wires

Expose the component that is no longer working to see where the wires connect. This may call for the removal of interior trim panels. In that case, carefully remove the panels since they grow brittle and delicate with age.

If the wires are in a plastic tube, remove them so you can touch and see the wires. Go wire by wire as you examine spots where the insulation has worn off, thus exposing the copper cable. Repair or replace damaged cables.

Test Voltage Drop

Get a multimeter and power on the problem accessory to check for voltage. Touch the multimeter’s negative leads to a good ground and the positive on the non-working component’s positive wire or terminal. This voltage drop test will help you find shorts and openings.

Split the circuit into thirds to narrow down the problem. If no electricity flows, you may have a faulty switch or wiring harness. If the course works fine, the problem could be a grounding issue.

To resolve a ground issue, check for corrosion on the ground bolt, a loose connection between the bolt and the wire, or dirt or water. Confirm the existence of a ground issue by getting a jumper wire from the load to a good confirmed ground.

Examine the Wiring Harness

If the grounding is fine, troubleshoot the wiring harness. Remove the wires from the accessory and trace them back to the first point of connection you encounter. You may need to remove the wiring from the protective plastic tube.

Disconnect the wires at the first point of connection you encounter. Now, test this stretch of wiring harness for continuity and electricity flow. Place multimeter probes on either end of the wire. The wire is likely damaged if resistance reads infinite or out of limits. Otherwise, a functioning wire should have a resistance of 0.3 to 0.5 ohms.

Repeat this process for all other wires in the wiring harness until you find the faulty one. If all cables pass the test, the problem could be in a different saddle section between the power source and the accessory. Once you identify the wrong wire, your options for fixing it include removing the faulty unit and installing a new wire or replacing a section of the wiring harness with a new one.

FAQ

What’s the cost of repairing an engine harness?

The cost of repairing your engine wiring harness will depend on the extent of the damage and the specific component that needs fixing. The price could be under $100 or more than $1,000.

You can save on repair costs by doing the work yourself if you are well acquainted with the procedure. Note that it might be more prudent to contract a professional instead if you are unsure of your ability to do the work satisfactorily. If you do not do the repair work correctly, you can expect the total cost to go up due to the subsequent remedial works.

Remember, cost concerns should not supersede safety considerations. You should spend whatever’s required to minimize the risk of fire and accidents due to incorrect repairs.

How do you replace a vehicle engine wiring harness?

1. Take pictures

Take detailed and extensive photos of the current engine wiring harness, connections, and routing. Use masking tape to label each relationship for future reference. Get a shop manual, then study the engine wiring diagram. Take note of the wires’ color codes. Over time, the wire colors will fade, and the stripes grow increasingly illegible.

2. Disconnect and remove the battery

Use a socket wrench to get rid of terminal clamps. Begin with the negative, then move to the positive. Hold down the brackets that hold the battery in position. Steer clear of stray sparks by setting the battery outside at a significant distance from the car.

3. Remove the harness

Work through the individual connections of the harness. Get rid of the primary bulkhead connection situated at the firewall. This is where the harness plugs into the vehicle to connect to the car’s central computer.

The majority of the engine connections are snap-in plugs. Still, use a tiny screwdriver and socket to eliminate assorted retainers and clips that hold the harness in position and unbolt the starter wiring and alternator. Knock, crank, and other hidden sensors may be difficult to reach and easily overlooked. So be thorough and work methodically.

4. Jack up the vehicle

Lower the vehicle onto the stands. Remove the wire connections underneath the engine. Separate harnesses, such as the engine fan and lights harness, will be intertwined with the engine harness. Separate and isolate these, as removing them may not be necessary.

5. Label new connections

Use masking tape to label new connections based on the labels, photographs, and documentation. Sort any tangled wires, and make sure you understand their installation and routing before you can proceed. Once you are done, you can then install the new cables.

6. Install new wiring

Install new wiring, connect plugs, tuck the wires back into their respective conduit or secure them to the engine or chassis. Note that wiring harnesses can be deceptive regarding split points and wire lengths.

If you finalize wire routing before you connect anything, you may discover that you have too little or too much wire for making connections or snaking around obstacles. Make sure the cables are routed away from exhaust pipes and moving parts. Lower the vehicle, reinstall the battery, start the car, and inspect the installation.

Don’t Compromise Quality

Choose a product that aligns with your engine wire harness requirements and ensures reliability. Our OEM wiring harness solutions offer flexibility to meet your specific needs. You can choose to replace a single harness, rewire a specific area of your vehicle, such as the engine compartment, or opt for a complete bumper-to-bumper rewiring by buying all the necessary harnesses at once.

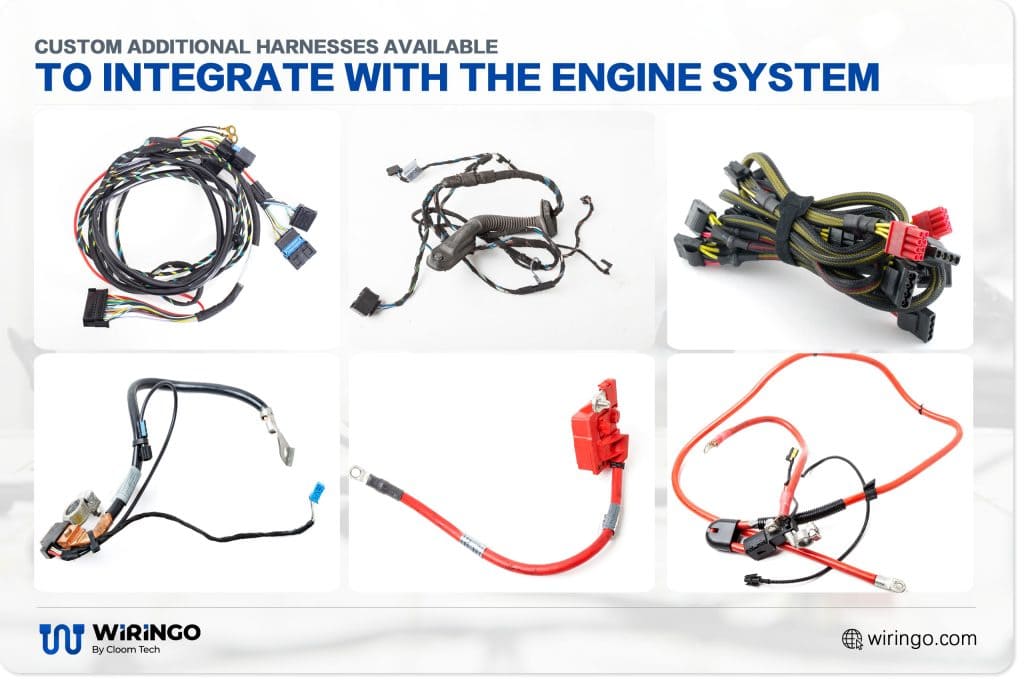

If your vehicle includes factory-installed options like rear window defogger, air conditioning, or power windows, additional harnesses are available to integrate seamlessly with the main system, just like at the factory.

Get in touch with us for help with your cable assemblies.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.