In the world of technology, flexible electronics are becoming a game changer. These electronics are lightweight and malleable and change many properties of the product or equipment. One of the significant components is flat flexible cables, and the FFC cable assembly makes these electronic gadgets more portable and compact. Let’s read about these cables in detail.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

What are FFC cables?

FFC cables are flexible electronics and refer mainly to very thin and flat cables, which you will generally find in high-density electronic devices such as cell phones and laptops.

Ribbon cables are another flat, flexible cable, and FFC cables are miniature. The cable has a plastic surface that is flat and flexible. Several thin solid conductors bind to form a ribbon cable. There is a stiffener at the end to make the cable insertion easier.

FFC cables

Specifications of FFC cable assembly

When you choose or design an FFC cable for your application, you are supposed to consider the following.

The number of conductors

You can also refer to them as pins. These are the total number of conductors that a Flat Flexible Cable has, which can vary from a few to 100. If an FFC cable has 30 conductors, you can call it a 30-pin FFC cable.

Exposure length

As the name clears, exposure length is the length exposed at the cable termination for electrical contact.

Stiffener

There is a stiffener at the opposite end of the exposed end of the cable, and the stiffener makes it easier to form ZIF and LIF connections or to provide strain relief. The stiffener makes the end of the cable slightly thicker.

Conductor size

Conductor size refers to the thickness and width of the conductors.

Pitch

The Pitch refers to the space between the center of one conductor and the neighboring conductor’s center. Sometimes, you will find different pitches in the same FFC cable; however, this is rare. You can get FFC cables in different pitches, including 0.500mm, 0.625mm, 0.800 mm, 0.630mm, 1.25mm, 1.00mm, 1.27mm, 2.54mm, and 2.00mm. However, the most common pitches include 1.00mm, 0.500mm, and 1.25mm. You can also request customized pitches from the cable manufacturer.

Type

The FFC cables fall into different categories. Some cables are Type 1 or Type A, and these have all exposed contacts at the same end of the cable. Some other FFC cables are Type 2 or Type D, which have exposed contacts at opposite ends of the conductors.

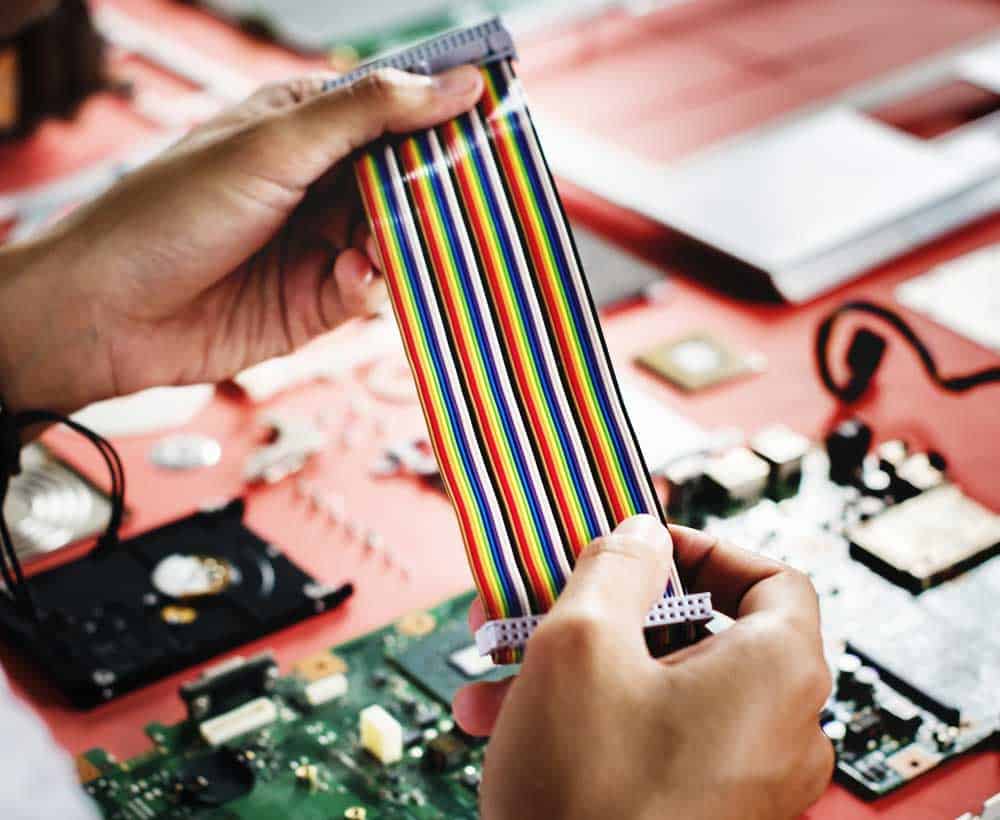

Flat rainbow ribbon cable

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

What can FFC cables be used for?

In high-density electronic systems requiring high flexibility and weight and space limitations, FFC cables are the best. For example, for folding mobile phones or for moving printer heads.

Commonly, you can find these cables in high-flex electronic items plotters, copiers, printer connections, LCD applications, DVD players, signal transmission, fax machines, and plate board connections. FFC cables have become more common in almost all modern equipment.

Also, the different connector types, variable pitches, cable adaptability, and cost-effectiveness of FFC cables make them suitable for many other applications.

Why Choose FFC Solutions over Wire to Board connectors?

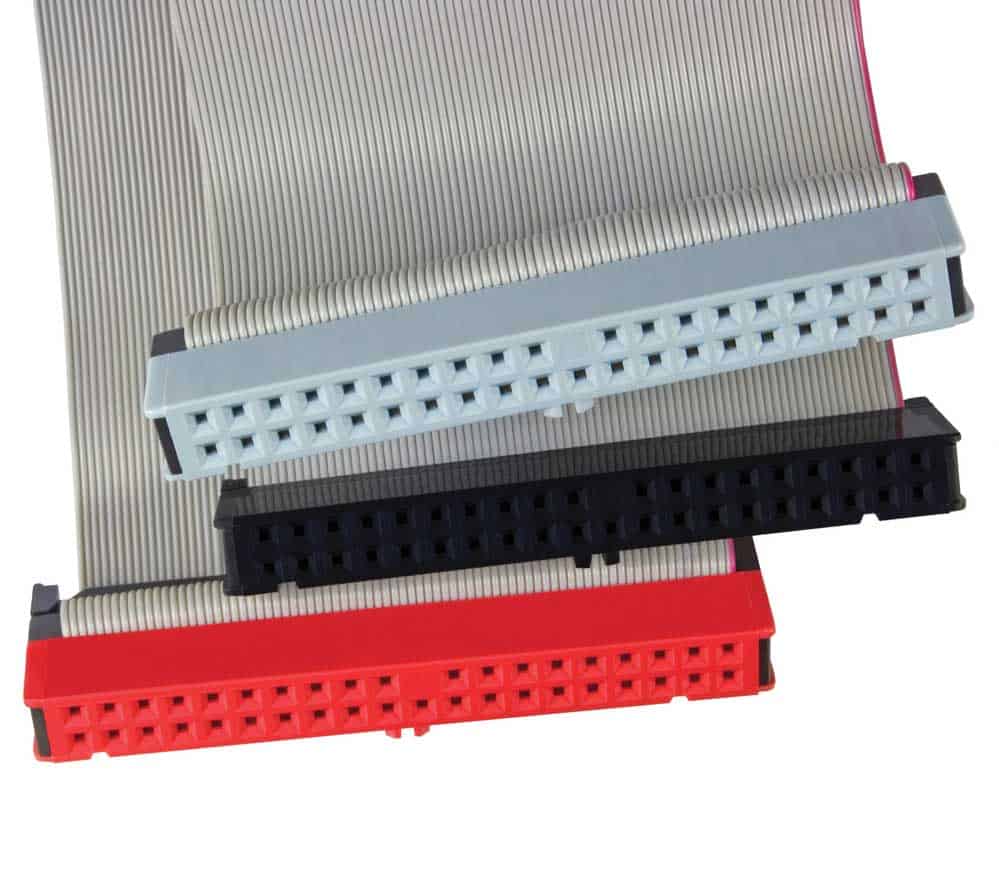

There are several solutions for wire-to-board connections, such as IDC/IDT and discrete wire cables. Then why do you use FFC cables primarily?

Flexibility

The main advantage of the FFC cable over round cables is its less space, higher flexibility, easy cable management, and ability to offer better RFI/EMI suppression. It also makes you get rid of wire coupling issues. In addition, because the wires are protected individually and not wrapped many times over by different materials as round cables are, they are lighter in weight and offer greater flexibility.

ZIF connectors

FFC connectors provide a low-height profile, lightweight properties, and a small PCB footprint. Also, they are effortless to use for operators. All these FFC connectors are ZERO Insertion Force connectors, meaning you need not apply force on the cable during the assembly. As a result, it makes the process trouble-free and reduces the chances of damaging any contacts. A locking actuator keeps the cable in place in high-vibration and shock applications.

Pre-formed and enhanced cables

You can order pre-formed FFC cables based on your exact specifications. You can get them as single or complex multi-fold according to your design. Your flex cable assembly manufacturer can also provide sticky tape, labels, or black insulators if required.

IDE cable connectors

Custom FFC cable assembly at Wiringo

At Wiringo, you can get a wide range of FFC cables compatible with all ZIF connectors, giving you low-profile, wire-to-board connections. Such cables are ideal for various instrumentation, POS systems, and medical electronics. Here are some characteristics of our custom-designed FFC cables:

- Available in different pitches such as 0.3mm, 0.5mm, and 1.0mm

- Cables have up to 80 conductors according to the pitches required.

- Type A and Type D contacts

- Cables manufactured using UL 20624 certified PET material. On request, we can also provide cables with high-temperature options.

- Pre-folded cables available on request

- Option for Gold-plated contacts available

- Measurement customized to your requirements.

Conclusion

Flat flexible cables are most suitable for applications where all types of solid and stranded wires and cable assemblies fail to work. You can flex an FFC cable thousand times without damaging its conductors. We have a wide selection of FFC cables most suitable for plug-in and soldering connections. We can also provide custom cables based on your requirements of Pitch, several connectors, terminal type, and length. Request a quote and get your customized FFC cable assemblies in no time.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.