We usually tend to ignore the FFC. They are one of the essential parts of the electrical appliances we are so fond of in the current age of technology.

We are about to find out exactly why these FFC are so popular in the electronics world today. Know how you can make the best and most informed decision to choose the right product. Are you ready to embark on the journey to know more about FFC?

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Chapter 1:What is FFC?

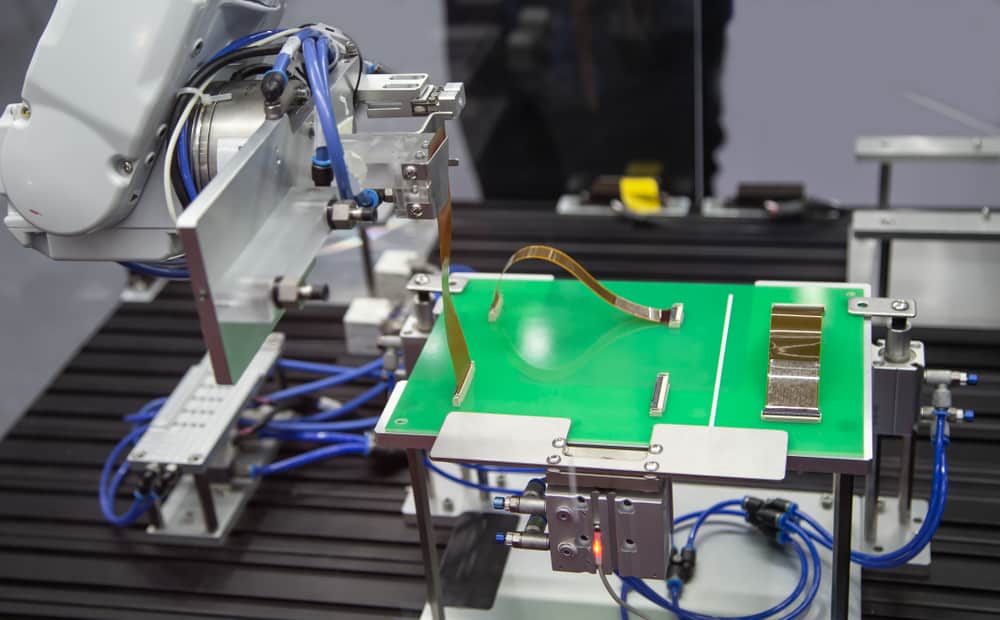

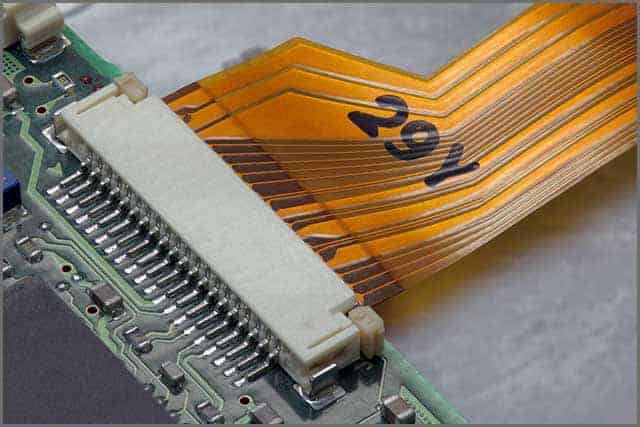

If you are using a tech gadget, you probably have many small cables inside it to make it work – wires that connect the circuit board. While round cables were once the choice for some, experts saw a common problem with them. For instance, round cables meant that the wires would wind up over each other. Instead, they saw that choosing flat cables will lead to easy management. Plus, flat cables are lighter in weight and offer more flexibility, something you are looking for today to make electronic gadgets portable and making them weigh as little as possible.

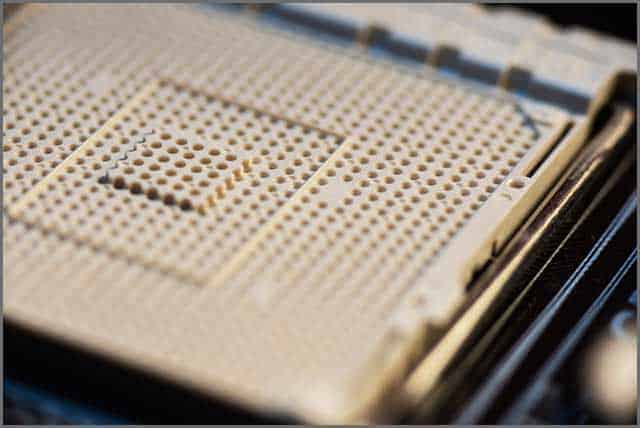

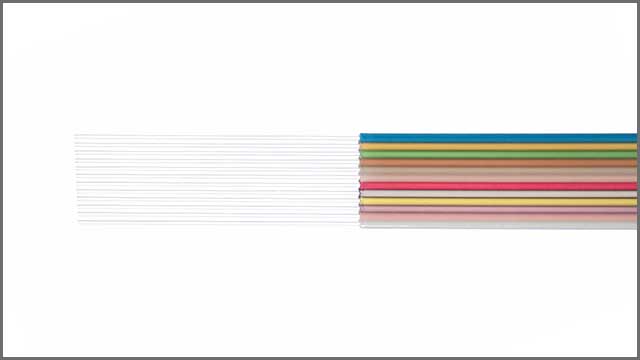

A flexible flat cable or FFC is an electrical cable that is both flat and flexible.

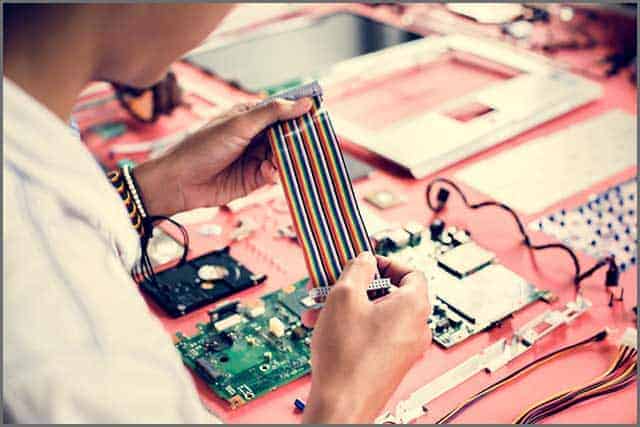

FFC is a miniaturized form of the ribbon cable that is flat and flexible as well. You use the term FFC, however, to refer to the fragile flat cable. These are found in everyday gadgets we use, including our laptops, tablets, and smartphone.

Think of your iPhone. Did you know that a flat cable is what joins your iPhone screen to the circuit board? If the flat cable breaks, your iPhone will stop working. In any device that you are looking for increased mechanical flexibility, you need an FFC. Unlike round cables, FFC’s put less stress in the components, ensuring you have less worry about any breakage.

Additionally,

The use of FFC will also differ according to the device. For instance, automotive use shielded FFC because they need high-density mounting and fine lead pitch, along with other factors like high heat resistance. You do not have these properties for FFC’s that you use in other consumer electronic products.

Interestingly, the FFC technology was made by Cicoil Corporation back in 1956, and since then, it has been a popular cable we use in many of our electronic gadgets.

Applications:

After the discovery, these cables were immediately used to replace stiff, round, and bulky cables in the computer industry. Today, their use has become tenfold. Today, you use them in most electronic devices like computers, printers, and so on for their simple, efficient structure and low cost due to standardization.

Now, we will talk about the specifications of FFC, which is essential for better utilization of the cable.

Chapter 2:FFC of Specification

The specifications of FFC are of 5 types. It is highly important for you to understand more about these specifications so that you can select the most efficient of FFCs for better use.

2.1: Pitch

Pitch refers to the distance between the center of one conductor to the center of the neighboring conductor. You can better understand it as the space between the conductors in the FFC. This space varies according to the type of FFC used. There are various pitches available like 0.500 mm,0.625 mm, 0.635mm, 0.800 mm, 1.00 mm, 1.25 mm, 1.27 mm, 2.00 mm, 2.54 mm.

You can choose the FFC pitch according to your use. Do note though that many providers only supply pitch types from 0.5 mm to 1 mm, as they are the most popular. If you are looking for something else, you might want to ensure that your provider has got the pitch you need.

2.2: Types

You have two different types of FFC cables. Since you use FFC connectors for mating cable and the circuitry inside the device in wire to board devices, knowing which one you need can help you.

You will find two types of FFCs available:

1.The Type 1, or Type A- These FFCs have the contacts on the same side at each end.

2.The Type 2, or Type D – You can see the contacts naked on both opposite sides of the cable for these particular types of FFC. You will see that when the cable is kept on the table or a flat surface, one end will have face-up contacts and the other end will have face-down contacts.

2.3: Exposure Length

You will be able to understand the exposure length of the electrical conductor easily. Determine the length of the electrical conductor exposed at the end of the cable.

2.4: Conductors Size

You fill to understand the size of the conductors by the measurement of the width and the thickness of the FFCs.

2.5: Stiffener

You will see that most FFCs have this extra material attached on the opposite side of the exposed length of the cable. It helps ZIF (Zero Insertion Force in IC circuits) or LIF (Low Insertion Force) connections.

The next chapter will tell you all about the difference between the FFC and the FPC, which will tell you why FFC is a better product.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Chapter 3:FFC VS FPS

What is the FPC cable?

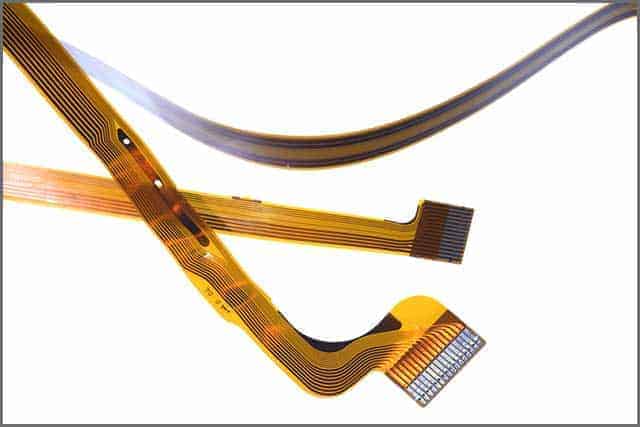

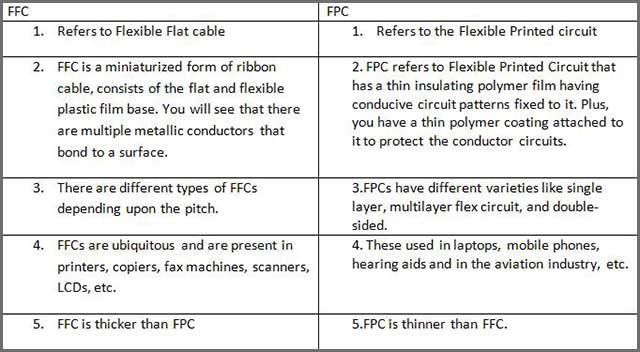

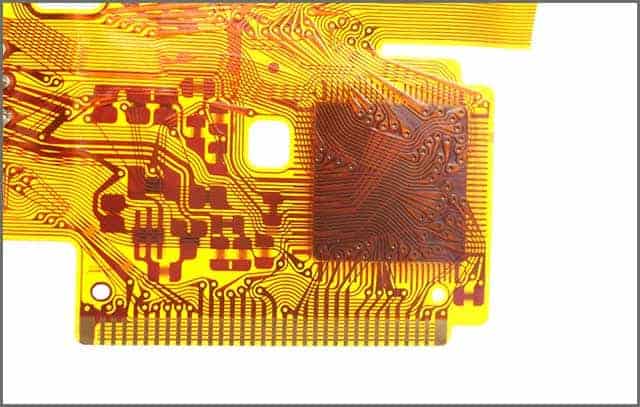

FPC refers to Flexible Printed Circuit. There are two parts to talk about here. One, it has a thin insulating polymer film having conducive circuit patterns fixed to it. Then, there is a thin polymer coating attached to it to protect the conductor circuits.

It is one of the most important interconnection technologies used extensively in recent times.

The production system of FFC and FPC is completely different. FPC was found to be more vulnerable than FFC.

In the next section, you will learn about the advantages of using FFCs.

Chapter 4: Why Flat Flexible Cable solution is the best?

FFCs are tiny, flexible, and can be freely bent and folded that will help to reduce the space needed in electronic devices and reduce design costs. They have high rest resistance (110 degree Celsius) and low connection resistance (20 m or less). They are thick and therefore not fragile enough to break.

You can blend, wind or fold FFCs as you want, according to the spatial structures of appliances. It can move in any 3D space and can stretch. That makes FFCs be able to integrate the wire connections and the device components.

FFCs also have the added advantage of being cables with the property that allows good heat dissipation and weldability. It is also easy to use because it can be very easy to install. The overall cost is not that high. Plus, the combination of the softness and hardness is the formula that makes the cable flexible, giving it its well-deserved name.

However, do note that connecting flat flex cables can be more difficult than it seems. If you want to go over the process, here is a good video that explains it.

Flat Flexible Cable solution advantage over IDC/IDT or discrete wire types.

If you are looking for wires for your board connections, there are several choices. So, why will you want to go for the FFCs over the IDC/IDT or discrete wire types?

FFC gives you a one-piece solution to all your difficulties regarding purchasing wires. It does not have separate male and female connectors. So, it saves you both the labor cost for assembly and makes using and storing easier.

FFCs weigh less and do not take up much space. You can use FFC’s for any of your board-to-board interconnect requirements.

FFCs are usually ZIF; they immediately lock into place. There is no further force exerted on the contacts of the cable because of the connectors. In appliances with high shock and vibration, actuators are put in place to hold the cable together.

The devices where mechanical movement is a must is much better off with the flat flexible cables. There are several reasons for this. For one, the moving part needs the stability of the flat cable. Appliances like scanners or photocopiers have moving arms which are more suited to FFCs.

Did you know that you can bend FFCs several times without breaking? Yes, they will not snap like other round wires that may snap once the pressure input on the crimped areas. The movement of these crimps in housing might also cause severe danger and hazards.

Let’s know about the various products you can get hold of from us in our next chapter.

Chapter 5: FFC Cable Suppliers

We deal with flexible film products like FFCs and FPCs. Our FFC connectors are the best suited for the high-density board to board connections, able to board as well as cable to cable connections. Our FPC connectors are tiny so that they do not take up too much space on the larger wire to board interconnects.

The products that are available with us are:

1. Flexible Flat Cable Accessories

2. Flexible Flat Cable Connectors

3. Flexible Flat Cable Contacts

4. Flexible Printed Circuit Connectors

5. Ribbon Cable Connectors

6. Ribbon Connector Accessories

Our products are further divided into groups:

1.Amp-Latch Ribbon Connectors- This offers fast and safe connections without stripping or prepping wires

2.Micro-Match- The newly introduced contact spring system helps prevent corrosion.

3.1.5 mm Amp Mini CT Connectors- The tiniest available wire to board connections.

4.High Performance Interconnects (HPI)- We have the best wire to board HPI at different pitches.

5.Dynamic Series- The PCB connector family is the best in environments which have lots of vibration.

6.2mm Amp CT Connectors: We have these especially for industrial usage.

7.Pivot Connectors- This is our most user-friendly product for terminating connections with low power, and it needs no extra tools.

We welcome all orders of both small quantities and large quantities.

Conclusion:

FFCs are very important for the efficient working of electronic goods. It is better to gain information and get the best and most reliable products in the market to ensure that you get greater efficiency. Get in touch with us today to get more information about FFCs and have in-depth knowledge about our products through custom solutions.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.