About Fiber optic pre-terminated assembly cable, With the number of optical fiber types and deployment strategies emerging, it’s hard for IT managers to make a choice that works best for their network. Moreover, they must set up the system quickly, works well, cost less, and can be expanded as the business grows.

The battle is between pre-terminated and field-terminated cable assemblies among all choices. Let’s see which one works best for your situation.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Pre-Terminated Fiber Optic Cable Assemblies vs. Field Terminated ones.

Electricians often debate what to choose while working on a field, between pre-termination and termination at installation. Therefore, here we have compiled some facts to end the debate once and for all.

Field Terminated Cables

Field termination ends a fiber optic cable after it has been put in place. Thus, you will put the cable across the points, stretch it to determine length, cut it accordingly, and place the connector on each end. After that, the patch panel attaches to it. Each cable has a connector attached.

A technician only needs to stretch the wire to the right length and clip it with the right tools to do this type of termination. Moreover, you must take several steps to successfully terminate a cable, including de-spooling the cable, mixing epoxy, installing connectors, polishing the ends, and finally testing the connection.

Here are some pros and cons of field termination

Pros

- Wires in precise length avoiding any wastage and damage

- Easy pulling of cable through nooks and corners

Cons

- Increase in labor cost since extra work is now due on the field

- Compromised quality since your technician might not know about putting the right connectors

Pre-Terminated Cables

In “Pre-terminated” or “Factory terminated” fiber optics, the optical fiber cables have their connector attached at the time of their manufacture in the factory. The technique for terminating pre-terminated fiber optic cables is the same as that for field-terminated cables, except it takes place at the factory. These cables offer

- Better performance

- Smooth consistency

- and end-to-end attenuation

Thus, many users prefer them in fiber patches and pre-terminated enclosures. Installing these wires in a network also takes less time and skill than traditional methods.

Pros

- Greater performance since the manufacturers terminated the cables with high-quality, compatible connectors.

- Cuts down time and cost as these cables are ready for installation.

Cons

- Waste of wires as the manufacturers make the cables at a universal length and not on a specific field.

- Installation difficulties as the connectors may collapse in some areas of installation.

So, what to choose?

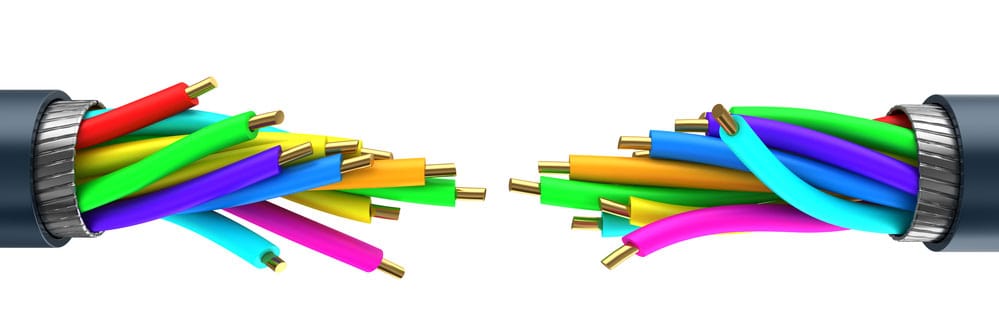

Caption: Fiber optic cables without termination

There is no denying that factory terminations provide superior quality cables and deliver more stability in performance than the field termination method. However, its usefulness lessens by size and cable track factors.

Pre-terminated cables work best when the cables are neatly arranged around system panels and there aren’t a lot of empty spaces. Also, these cables are the best choice when you need shorter cables already set to a certain length. Such termination could improve local cable providers’ installations and end the issues of immature installations by trainees.

On the other hand, field-terminated assemblies are the way to go when connecting fiber optics over longer distances or through immeasurable tracks. Here, you might think that pre-terminated cable can also do the job; however, it is unreliable. Thus, engineers may prefer field termination of cables as it allows for greater adaptability and smoother pig tailing.

As additional information, you can always go for hybrid cable as an optimal option. Big cable bundles are available, with a connector at one end and another open for field terminating. Hence, you can have the convenience of one end of the fiber optic cable with a proper connector termination and the adaptability and ease of installation afforded by leaving the other end without a connector.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Advantages of Pre-terminated Cables

Pre-terminated assemblies have many benefits. Regarding speedy installation, pre-termination has the way to go for data centers and industrial networks. Also, these cables s are widely used due to their many desirable characteristics.

Low costs

Since the assembly is already terminated, there is no need to buy expensive tools or connections to get the job done. That results in a lower cost of ownership. Also, you do not need to rework them and go for any transmission testing, as they do everything at the factory.

Shorter turnarounds

As you do not terminate the cable in the field, the turnaround time is much shorter. Once you’ve discussed your needs with a reputable manufacturer, you should have the cables in two to four business days.

Quick Deployments

These pre-terminated fiber optic cables drastically reduce deployment time by as much as 80% in some cases. Because they are easy to plug in, you can set them up in no time.

High Performance

Pre-terminated fiber optic cables guarantee the maximum level of precision, which is essential for fields that need equipment reliability. Also, they go through multiple quality assurance checks before they reach the consumer. With the test reports that come with the assemblies, you can be sure they will work well.

Reduces Downtime

These fiber optic cables make it simple for data center administrators to reduce downtimes. These fiber optic cables make it simple for data center administrators to reduce downtimes. They can produce a temporary connection in downtime. As the situation is in your hands, you can remove them from the system.

Minimizes Carbon Footprint

Pre-terminated assemblies require less cleaning after fixing, which minimizes the carbon footprint. Thanks to the pre-terminated design of these cables, there is nothing left for combustion. Businesses may minimize their carbon footprint and increase their sustainability and waste reduction efforts with the help of such techniques.

Tips for choosing Pre-terminated Fiber Cables

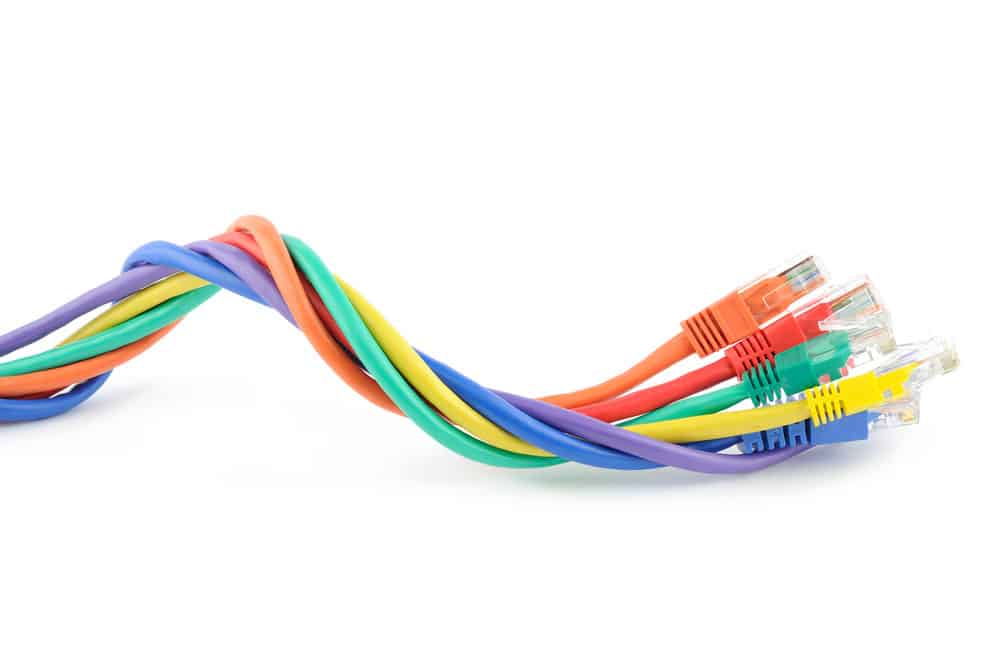

Caption: Computer fiber optic cables

It can be just as hard to choose pre-terminated fiber optic assemblies as it is to choose field-terminated assemblies. To cut down to the chase, we have presented a few tips to help you choose a good pre-terminated cable.

- When selecting pre-terminated assemblies, cable construction is a key factor to think about. Thus, you can choose between indoor plenum for closed spaces and outdoor cables for harsh environments and add additional armor to them.

- The pre-terminated optic cables are available in several fiber kinds. Some are OM1, OM2, Laser-optimized cables OM3, OM4 cables, etc.

- You can also choose between different connector types, like the SC connectors, that are simple to attach and inexpensive. Also, you can choose the push-and-pull connectors for Small space areas.

- Multiple strands are possible in a cable, with each strand wrapped twice around the central wire. Typical configurations include two strands (duplex), four strands, six strands, eight strands, twelve strands, and even twenty-four strands.

Considerations to install a pre-terminated cable

While installing the pre-terminated cables, you must remember a few precautions. That is

Fiber optic pre-terminated assembly cable: Protection of fan-out wires and connectors

During the installation of the pre-terminated cable, it is important to keep the fan-out cables and connectors safe. We recommend using a protective tube before, during, and after installation. After installation, you can remove the protective sleeve.

Fiber optic pre-terminated assembly cable: Outdoor electrical conduit

The use of pre-terminated wires is also permissible in the open air. However, you should not bury most varieties without some sort of preservation. When used outdoors, the effects on the environment are magnified; especially the rodents pose a serious risk. Thus, it would be best to have a conduit when bringing pre-terminated cables outside. Also, an armor jacket protects the pre-terminated cables, which protect the wire from significant damage.

Fiber optic pre-terminated assembly cable: Other Installation Precautions

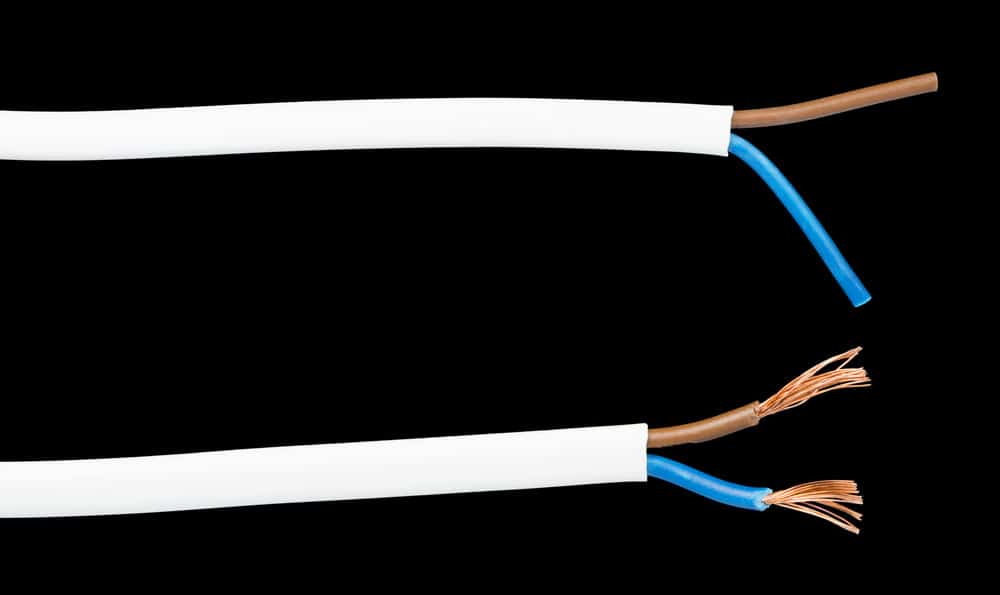

If you have the option, you should lay out the cable. If everything else fails, gently pull the cable. As you pull the cable, its strands face strain inside.

Remember that this tensile strain only applies to the main strands, not the fan-out cables. It is because the tensile ability of fan-out wires is significantly lower. To overcome this, you can get the cables with a pulling rope at the end of the pre-terminated wire. If you pull it, the tensile force will apply to the installation cable rather than the fan-out cables.

Caption: Exposed cable strands

Conclusion

Even though field termination seems a good method, most people buy pre-terminated cables. It is due to their higher quality and ease of installation that saves labor and time cost, all in one. Nevertheless, the choice depends on the system that you are working on.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.