Ribbon Cable Assembly Manufacturer

With over a decade of experience, Wiringo is a leading manufacturer of high-quality ribbon cable assemblies. Focusing on reliability and innovative design, we offer customized solutions for various industries.

Our Clients

Also known as flat ribbon cables or planar cables, the ribbon cable assembly is a flat and rectangular cable comprising multiple conductors or wires placed parallel to each other.

Benefits of Ribbon Cable Assemblies

Ribbon cable assemblies have been a critical component of various industries due to several benefits they serve.

Space Efficiency

As multiple conductors in ribbon cables lay flat, they take up minimal space. This makes these ribbon cables ideal for applications with limited space such as dense circuit boards or compact electronic devices.

Easy Assembly

The uniformity of conductors makes it easy to terminate and route them. Thus, the fast assembling process speeds up the manufacturing and reduces the chances of errors considerably.

Reduced Crosstalk and Interference

Due to the close alignment of conductors in ribbon cables, there is minimal electromagnetic interference between adjacent wires. As a result, these cables are suitable for high-speed data transfer with stable signal transmission.

Better Organization

Due to the parallel wires, the cables have neat organizations, making them easier to manage. It also simplifies the installation and maintenance of the wires.

Get A Custom Wire Harness Quote Today!

Types of Ribbon Cable Assemblies

Wiringo offers a range of custom ribbon cable assemblies with high-quality features that make them suitable for various demanding applications.

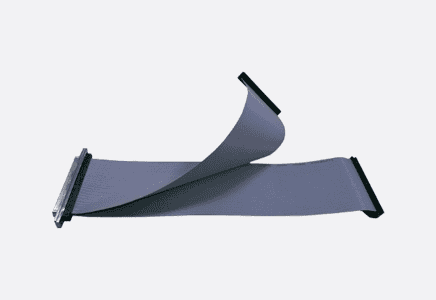

Round Conductor Flat Cable Assembly

Grey, the typical ribbon cable, is employed for its convenience in mass termination. For applications requiring flexibility with durability and long-lasting performance, these cables are ideal.

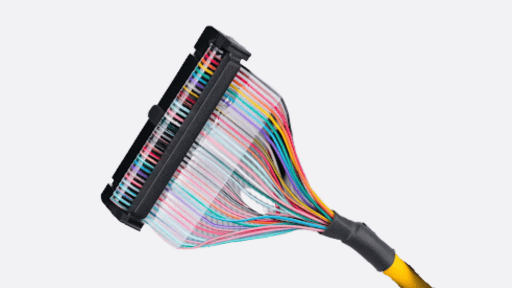

Rainbow ribbon cables or Color-coded Flat Cable Series

Rainbow ribbon cables are built like regular ribbon cables. However, their default colors make them easier to categorize and spot. For applications requiring visual distinction, rainbow ribbon cables are perfect for communication systems, electronics, and computers. In some cases, it is possible to separate the ends of this structure for individual severance.

Twisted Pair Flat Cable Series

Twisted ribbon cable differs from most cables because they twist and then join the pairs of conductors together. The twisted pair designs of these cables ensure high signal integrity due to reduced crosstalk in critical wiring systems. In addition, it has sections that are not twisted. Thus, the standard IDC ribbon cabling methods can terminate the connections and PCB headers.

Bonded Ribbon Cable Series

The ribbon wire (coaxial cable, multi-conductor Cable, and single hook-up wire) is arranged differently from standard ribbon cables. After you decide on an item, our crew will use adhesive glue to bond the components permanently. Bonding serves the same organizational, identifying, and bulk-terminating functions as the other constructs.

Products

Wiringo offers a range of ribbon cable assembly products suitable for different applications, machinery, and industries.

Hybrid Ribbon Cable

Our Hybrid Ribbon Cables utilize a compact design that incorporates wires of varying sizes and types, such as coaxial and insulated parallel pairs, into a single cable.

Flexible Ribbon Cable Assemblies

Our high-performance flat-ribbon cables have robust outer jacketing to withstand physical movement, which is best for severe conditions where conventional PVC or TPE cables would quickly deteriorate.

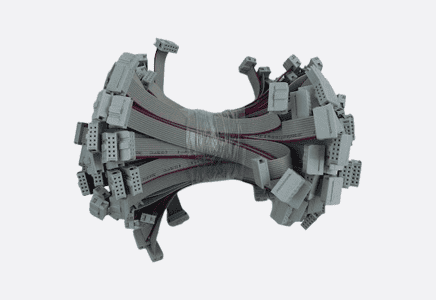

IDC Ribbon Cable Assemblies

We use IDC connectors with different pin counts depending on the customer's requirements.

Shielded Ribbon Cable Assemblies

These assemblies have a shielding layer of braided metal or foil around the conductors to prevent EMI. They are common in applications requiring high-speed data transfer with signal integrity.

Molded Ribbon Cable Assemblies

Available in different variants depending on the connectors, such as male/female, right-angle, or straight connectors.

Intermittent-Bonding Ribbon Cable

Increased adaptability, simple termination, 180-degree turn at isolated portions, and neat wire arrangement benefit the intermittent-bonded, flat cable.

Manufacturing Capabilities

Wiringo offers you simple and complex ribbon cable assemblies that require customization.

Services

Our comprehensive range of services ensures durability, precision, and seamless integration of our products in every system. Our services include:

- Design review

- Prototyping

- Production and assembly

- Testing

Cable Connectors

Wiringo uses a wide range of cable connectors for flat ribbon cable assemblies between 0.635 and 2.45 mm pitch. These include Molex Picoflex, TE Micro Match Sockets, and many varieties of IDC connector pitches.

Quality Testing

Wiringo ensures high-standard quality testing of all completed products to pass all quality control checks, including UL product certifications, DIN ISO 9001-2000, ISO 14001, ISO 13485, and ISO/TS 16949.

Prototyping

We offer rapid prototyping services to bring your designs to life quickly. Prototyping helps ensure the product's functionality, allowing for efficient product development.

Customizations

With Wiringo, you get tailored solutions to meet your specific requirements, ensuring that the requested product fits your project needs seamlessly. We offer a range of custom solutions, including:

- Cable types

- Connector orientations

- Circuit sizes

- Length

- Labeling styles

- And more

Flexible Order Quantities

Thanks to our extensive manufacturing plants, we can accommodate small and large order quantities, allowing us to meet your variable production demands.

Why Choose Wiringo?

With a dedication to excellence and customer satisfaction, Wiringo handles every project with utmost care and expertise.

Custom Solutions

We offer bespoke designs to meet your specific requirements. Whether you need custom configuration, better shielding, or specialized connectors, we can tailor our solutions based on your needs.

Industry Expertise

Having over a decade of experience and extensive knowledge of different industries, we have the expertise to handle any challenge and deliver practical solutions on time.

Unmatched Quality

We ensure each ribbon cable is made with premium quality materials and precise engineering, ensuring optimal performance and long-lasting durability.

Global Reach and Support

We can support our clients with scalable production capabilities, quick lead times, and dedicated customer support.

What Our Customers are Saying

See what thousands of happy customers say about Wiringo’s commitment to product quality and customer service.

I have received an shipment of the cables that was supplied (p/o : 5130903714 )

I would like to say thanks you , to you and your staff ( factory ) well done.

I am very happy with the quality of the work, ( C )

Thank you very much for your hot support and efforts for our parts supply.

We received your DC cables with thanks a lot.

All parts passed inspection successfully!

Lead Engineer

I just received the cables. Once again, we are very pleased with the results. We are also looking forward to further cooperation in the future.

Please take care.

I could not ask for anything better in terms of quality since everything arrived in perfect condition.

Thank you very much and I look forward to future projects with Wiringo.

Thanks again for Wiringo's hard work in making this project a success.

Frequently Asked Questions

What are the flat ribbon cable applications?

Flat ribbon cables are common in applications requiring organized wiring and have limited space. They are widely used in electronics, computers, networking systems, robotics, medical devices, and automotive industries.

What are ribbon cable specifications?

The wire gauge of these wires ranges from 18-34 AWG. The spacing and number of conductors can differ in different ribbon cables. Besides, these cables have definite voltage ratings, flexibility, shielding, and RoHS compliance to meet the requirements of industries and applications.

What is the advantage of ribbon cables?

Ribbon cables allow easy routing in tight spaces, keep connections neat and reduce tangling, minimize EMI, offer long-lasting performance, and cost less than other complex wiring solutions. Another significant benefit is that they allow mass termination to specially designed IDC connectors.

What is the disadvantage of ribbon cables?

Some computers could also connect to the outside world. The ribbon-like form makes it hard to manage the wires, especially when you have a bunch of them. Because of this, round cables replace the ribbon cords for peripheral devices.

What are the connectors of ribbon cables?

Ribbon cables are primarily used for mass termination to IDC connectors with sharp, forked contacts that the cable must be pressed against to connect. Typically, termination occurs at both ends of the cable. However, in rare cases, like wire swapping, you will terminate one end of IDC. The other end would use a more conventional termination method like a crimping or solder-bucket connection.