Manufacturers have had to find a way to reliably transmit data from the screen to the motherboard without taking up too much room in their quest to develop ever-thinner gadgets.

That’s why “flex cable assembly” is commonly used. Smartphones today are a prime example of this.

The flex cable’s structure and adaptability allow it to execute the job, but the trade-off has a higher potential to be damaged.

Let’s dig into the complications and how to avoid them using professional help.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

What is flex cable?

The flex cable, or FFC (Flat Flexible Cable), is a crucial component of any electronic device, such as a mobile phone or tablet computer.

The flex cable’s primary function in mobile devices is to interconnect the motherboard to the LCD monitor, while its potential applications are far broader.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

How to suspect a broken flex cable?

A broken or intermittent display is the most telltale sign that you have a compromised flexible cable.

Naturally, this kind of gadget is useless.

Therefore, any procedure requiring opening the device must be carried out cautiously.

Most common causes of damaged flex cable

It takes only one broken flex cable to render an entire screen and gadget useless.

So, the flex cable needs careful handling, or it will fail to work.

- Incorrect installation of flex cable in the apparatus.

- Damage to the flex cable due to carelessness

- Pinch or pressure damage to the wire

- Failure to recognize the uselessness of one’s current methods

- Making adhesive contact with the flex cable

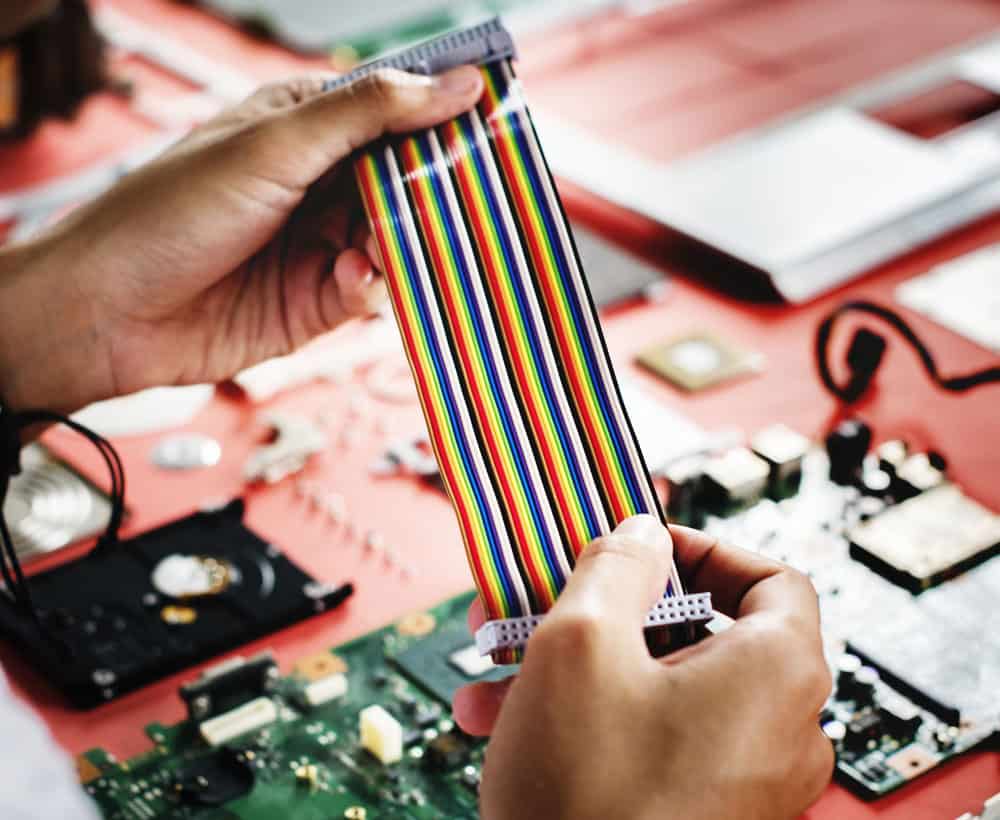

Caption: FFC with computer component

How to fix flexible “flex” cables that are broken or torn?

When it comes to completing the repair, poor handling is directly linked to its completion.

Suppose you’ve effectively replaced the monitor and are ready to reattach it to the CPU via the flex connection, which is when the cable is most likely to be broken or otherwise damaged if you store it in the wrong spot and then close the device.

If it is your first time making this repair, it’s a good idea to snap a photo of the device while it’s open so you have a reference for putting the cable back in its original spot once you’re done.

Tools

- Solder paste remover

- Adjustable heat gun

- Small scissors or surgical solder iron with miniature failure

- Desoldering braid

- Weld roller for electrical equipment

- Masking or sticky tape

- Razor blades with one edge or a surgery scalpel

- Flat blades

- Screwdriver

Instructions

Step 1

First, using the scissors, cut the torn piece cleanly along the two straight edges using the scissors.

or

Cut or rip as straight as a feasible non-torn section to get equal halves if the cutting takes too much time while tougher.

Then, please read the steps below.

Step 2

Scrape the insulation off one side of the cable with the single-edged blade to reveal the bare wire for the connections, which should be about 3 to 4 mm long.

Take your time and avoid damaging or removing the copper if possible. Getting anywhere is a slow procedure.

Then, please return to the cable’s back half and scrape it similarly to reveal the copper there.

The lacquer insulator is not as easily scratched as it appears in images.

Step 3

The third step is applying a thin solder paste eraser and coating all exposed copper sides.

If it spills over, that’s okay.

Heat the dough with the soldering iron to stick it to the cable’s copper section.

Take care of both sides. You should use a solvent or cleanser to remove any lingering dough.

However, be careful not to destroy the plastic insulation after placing the solder on each tin contacts.

To reconnect the cable, apply this to the connections of the two “flex” portions.

Use a desoldering braid to remove excess solder or to split two tracks that have become accidentally connected.

Step 4

Use a mask or sticky tape to attach the two cord ends ‘flex securely’ layered one on top of the other, with the ends aligned as precisely as possible and overlapping by about 4 mm.

Hence, the contacts are entirely in touch (without an electrical circuit).

Put a dab of solder solution to the connection point between the two pieces.

To rejoin the cables, heat the top sheet (using the heat gun at the welding station) gradually, avoiding overheating the insulator of the cable “flex” while melting solder uniformly enough to pull it over all of the contacts.

Step 5

The next step is to apply pressure between the 2 layers of cables using a flat-bladed screwdriver or a stiff metal plate and then perform circular motions with the heat gun to strengthen the weld’s hold.

Wait until the solder has cooled before removing the screwdriver (or metal plate) for approximately 30 seconds.

Remove all tapmmeter connections from end to end to ensure that there are not any loose connections.

You should weld the connections again with heat if you find any faulty ones.

Precautions

- There is a risk of worsening a bad situation if you try to fix a malfunctioning electronic card, as these cards typically have integrated components vulnerable to static discharge.

- Also, there is no way around learning how to precisely operate electrical solders on the card and typical parts to repair cables that ‘flex.’ Welded (and desoldering) equipment (iron tiny conventional welder and hot air cannon to heat and flowing factors) should also be available.

Conclusion

Flex cables are best when adjusting more wire in smaller spaces.

However, you have to handle them carefully and fix them in places with expert techniques.

After all, mishandling or incorrectly using a flex cable’s associated tools is the leading cause of this part becoming damaged.

If you want to handle it well, use only the provided professional tools and never touch it with metal instruments.

Here at Cloom, we offer flexible cable assemblies with careful handling so you get signals with minimal interference.

For getting services, contact us now.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.