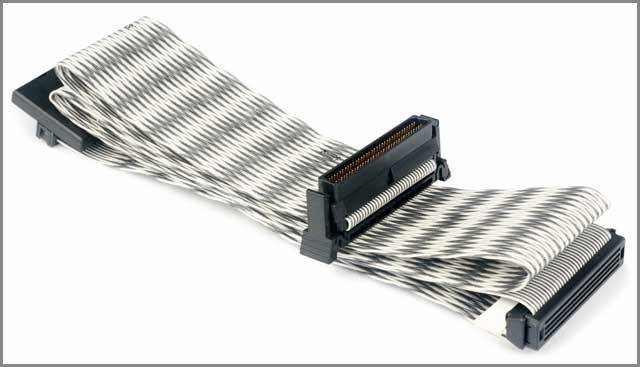

When it comes to ribbon cable assemblies, most project managers ask what kind of cable assembly they should use for their project? Either they should go for IDC ribbon cable assembly or crimp cable assembly? There is no hard and fast rule for selecting IDC cable assembly, depending on your requirements and project needs.

In this article, we will discuss everything in detail related to IDC ribbon cable assembly manufacturing.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

1. Common Ribbon Cables Specifications

If we compare the production cost and other factors with other ribbon cables, the IDC ribbon cable assembly is more comfortable to manufacture and less expensive. The production time for IDC ribbon cables manufacturing is less than many other technical cable assemblies.

The manufacturers do not have to strip the cable’s insulation before the termination, and it saves a lot of time and manufacturing costs. With the latest IDC ribbon cables equipment and tools, we have offered the most affordable cables assemblies in the Chinese market. As IDC ribbon cable assembly requires no crimping or soldering, the production team can act more effectively.

You don’t need to use any advanced or complicated device to terminate the IDC ribbon cable assembly, and any simple tool or even an essential hand press can do the job in IDC cables. You don’t need to invest in any new workforce for the termination of IDC ribbon cables.

IDC ribbon cable assembly is not a new term in the electrical field, and engineers and manufacturers have been using IDC ribbon cable assembly since 1950. Due to the wide applications and acceptability of the IDC ribbon cable assembly, we offer different designs and manufacturing options in IDC ribbon cables.

2. Advantages of Ribbon Cables

The increasing need for advanced cables for better transmission power in various appliances and projects requires modern solutions. There are several advantages of IDC ribbon cable assemblies that are an attraction for engineers in custom projects. Standard cable assemblies seem to be inappropriate due to custom design and size limitations.

Here are some significant benefits of using IDC ribbon cable assemblies for your project or appliance.

·The flexibility of the Use

The IDC ribbon cable assembly seems to be the best option for projects where you have limited space. Engineers find IDC ribbon cable assemblies more practical in custom projects as they can use these flexible assemblies in any project.

· Termination of the IDC ribbon cable

In different cable assemblies, terminating the meetings is an important step. Some cable assemblies are easy to manufacture, but you have to use advanced tools and equipment for the termination. You don’t need to do any prior insulation piercing; you can quickly get immediate termination with a simple hand press.

· Efficient transmission

Due to the use of quality materials in IDC ribbon cable assemblies, the current flows smoothly, and there are less leakage and wastage of power. With the greater current carrying capacity of the IDC ribbon cable assemblies, you get the wirings’ performance in less space.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

3. Applications of the IDC Ribbon Cable Assemblies

The IDC ribbon cable assemblies are most suitable for the wiring in tiny spaces. IDC ribbon cables are perfect for data and power transmission for smaller equipment like computing devices and other tiny appliances. For medical devices and other testing devices, these ribbon cables act as a connector between different equipment.

4. IDC Ribbon Cable Assembly Process

In this section, we will assemble an IDC ribbon cable assembly with the help of two IDC connectors. This process of making cable assembly is only for DIY activity. At CLOOM Tech, we have trained teams of professionals to manufacture state-of-the-art IDC ribbon cable assemblies.

You need to start the process by cutting a piece of ribbon cable of any required length. You can reduce the part of any period as per your custom requirements. As you will also use the connectors for the assembly, try to cut a little longer wire. Before connecting the connectors, ensure that you have identified the Pin 1 and line up the connector with the cable pins accordingly.

It would help if you also focused on the direction of the cable as both connectors must be facing the same direction. Once you have adjusted the connectors and the cable lines, press the clip so hard that it starts to clamp the cable. Once you feel that the thread fits the connector perfectly, you are good to go with your IDC ribbon cable assembly.

If your manufacturer has delivered your IDC ribbon cable parts, ensure that they have proper testing labs and all the details provided after a quality check.

At Wiringo, we have strict quality assurance standards, and every product undergoes these stringent tests before shipment. Once you have your delivery, you can check the parts for possible damage. If you end up using any damaged component in your project, it can affect the overall working of the project.

Color coding of the IDC Ribbon Cable

As there are several lines on the cables, it can be hard to manage the connectors and the wires in the same manner. There are specific color schemes for the wires, and these color codes reduce the risk of reverse connection of the IDC cables. There is a universal rule that the edge with the red stripe goes with pin 1. As you know that there are universal resistor color codes, the same color-coding goes for IDC ribbon cable assemblies. The brown color is for odd-numbered pins, and the red ones are for the even pins.

Cable Assembly Parts

The typical IDC ribbon cable assembly has some common elements that go with almost every design. To make the IDC ribbon cable, you need a ribbon cable of the length as per your project needs and two same IDC connectors. And to make an IDC ribbon cable, some extra tools like scissors to cut the wires machine for the termination of the wires.

5. Choose Wiringo as Your IDC Ribbon Cable Assembly Manufacturer

If you are trying to establish a project where you need to use the IDC ribbon cables, we can be your perfect partner. We specialize in manufacturing custom cables and wiring harnesses for the Chinese and the international market.

We are one of the top custom wiring harnesses and cable assembly manufacturers in China. If you ever need a trusted team to meet your custom needs, our team is always ready to serve your custom wiring needs. As we have described everything in detail regarding the advantages and manufacturing of the IDC cable assemblies, it’s time to make the right decision.

Your business needs your full attention to meet your future goals. To meet the market needs and to beat the competition, you need to focus on what matters. Setting up the IDC ribbon cable assembly manufacturing unit seems like a good idea, and we support your opinion.

But if you look deeper, you will realize that it is a complicated process, and you should leave it to the experts. Only an expert team can meet the custom needs for the wiring harnesses and the ribbon cable assemblies. No matter what kind of project you are working on, you can always turn to ribbon cable assemblies if you ever need to save space in energy transmission.

Conclusion

From choosing the correct cable assembly to selecting the right cable manufacturing company, we try to bring the best options for you. These components seem like more minor ingredients, but your project heavily depends upon these components. If something goes wrong with a single wire in your appliance, it can cause havoc for your project and the device.

With project analysis and choosing the best cable assemblies for your appliances. If you have any queries, you can get back to us at any time, and our customer support will contact you as soon as possible.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.