The performance of the cables must be top-notch since many human lives depend on them. Many factors affect cable choice in this category, and one must understand the available features and types. Further, choosing medical cable can be an uphill task for healthcare facility operators.

In this article, we dive deep into medical cables and avail all the necessary info.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Understanding Medical Cable

Medical cables are wires for hospital applications ranging from diagnostics to life support machines. The medical field relies on a comprehensive collection of cables for the different healthcare facilities’ other equipment.

Structure of Medical Cable

Medical cables have different parts, each playing a vital role in the performance of the line. Threads in this category have three sections, namely the jacket, insulator, and conductor.

The conductor is a significant component in the medical cable, and it is responsible for the transfer of electric signals from the power source to the device. Metals with high conductivity in solid, tinsel, or stranded form are standard healthcare machinery options.

Insulators are critical in the internal structure of medical cables. Resistance to electric flow is necessary for all lines helping prevent contact between the electrical conductors. Insulators also play a vital role in preventing electrical leakage to the patient. The composition of the insulator and the dielectric properties determine the efficiency of the insulation.

Medical cables are bound to come into contact with patients often. Thus, it is necessary to have an insulator to cushion patients against electrical charges. For this reason, the jacket part becomes an essential addition to any medical cable. The jacket is the outer shield protecting the insulator and the conductor, and it prevents any contact with the environment, cleaning, and sterilization components. The cable structure needs to adhere to the FDA and the ISO 1099 requirements for human safety and protection.

Materials for Medical Cable

There are different types of medical cables, and these cables vary depending on the materials manufacturers use and the specific cables’ usage. Biocompatible materials are vital due to human contact, and as such, Silicone is the best material for jackets.

For the other variations available, the purpose dictates the kind of content they use. The cables consist of conductors, insulators, and jackets, and all of these parts require different components. For medical lines, the producers need to use premium quality to ensure optimal performance.

Properties of Medical Cable

Knowing the different properties of cable in this family is critical in the selection process. The top elements to keep in mind regarding the properties of the medical line are;

Electrical Properties

The wires in any medical cable must be good conductors of electricity, and the line must also meet all the electrical requirements. The relevant medical control bodies set these requirements.

Mechanical Properties

Tear and wear are common for all cables, including those found in medical equipment and establishments. The mechanical properties affect the performance of lines, longevity, and flexibility. Again, the choice of materials is essential in determining whether a given brand has excellent mechanical properties or not.

Thermal Properties

Thermal conductivity is an intrinsic characteristic of medical cables. This aspect measures the ability of the line to handle and transfer heat. Different materials that make medical cables determine their thermal conductivity.

Medical Cable types

The healthcare sector relies on various medical tools. Such tools each need a different set of cables to function normally. Here are the types of medical lines available from multiple manufacturers across the world.

Single-Use Medical Cable

Single-use medical cables are mostly those that come into direct contact with the patient. They are suitable for a single procedure on one patient. Decontamination is not possible for such cables; hence. Reusing them will put the patient’s health in jeopardy. Exposure to chemicals and other environmental factors alter single-use medical cables’ functioning. The materials used in the manufacturing process are not ideal for subsequent uses.

Power Supply Cables

Equipment and devices in any health facility require power to function. Therefore, power supply cables are necessary for any healthcare setting. Various options are available for users, depending on the purpose. Before buying power supply cables, a review of the different wires is necessary to determine the best. The cables may suit various machinery in replacements or upgrades.

Coiled Cables

Coiled cables are similar to the regular ones, but their spring-like shape sets them apart. This shape allows them to cover more area when the need is and retract when not in use. Such a cable takes up less space in storage. Additionally, it is not prone to tangling like the other cables. They are commonly helpful in different medical equipment in ambulances and choppers.

Patient Monitoring Cables

These are cables that transmit signals from vital organs in the patient’s body to the monitoring machines. Ambulances, medical choppers, theatres, and intensive care units never lack patient monitoring cables. Currently, hybrid cables are taking over traditional lines, and hybrid can monitor multiple functions at a go, reducing the number of wires on the patient’s body.

Ultrasonic Cables

Medical cables make ultrasonic testing possible. The ultrasonic machines require a host of cables to transmit signals from the patient to the screens. Thus, ultrasonic cables are a vital part of this setup. Electrical conductivity and resilience are among the top features to bear in mind when shopping for ultrasonic cables.

(Bluetooth remote ECG with cables and receiver)

Cables for Medical Applications

Cables are crucial in many medical applications. They allow electrical current to pass through and power all the machines for different procedures. Below are some of the lines for medical applications available in the market.

Surgical Lights

High-quality lighting is critical for all operating procedures, as the surgical team needs clear visibility. Ambulatory surgical centers require lighting, and this center is among the areas where different medical cables come in handy.

(Operating room with modern surgical lights)

Surgery Robot Systems

Robotic surgical systems are among the areas where medical cables are necessary. The robots have arms that hold surgical equipment and a camera to transmit a live feed.

(Robot surgeons)

Laboratory Equipment

The laboratory is a critical part of the healthcare system as it plays a vital role in diagnostics. The different equipment requires cables to operate, and other assemblies are available in this part of a facility to assist with the machinery’s various functions.

(Interior of a medical laboratory)

Medical Imaging and Diagnostics

Medical imaging allows the medics to create visual images of the internal body for clinical examination. There are numerous imaging machines, and each requires a host of cables to function normally.

(CT scanner)

Treatment Units and Operation Tables

Operation tables are necessary for both minor and major surgeries. Treatment units are also a vital part of health care systems, and both of them require cables to perform different functions.

(Modern surgical room with operation table)

Electronically Adjustable Hospital Beds

Electronically adjustable hospital beds make work easier for medical practitioners. Such beds use different types of cables that are necessary to facilitate the functionality of the bed.

(Electronic hospital bed)

Hospital Lighting Units

Lighting is critical for every facility offering healthcare services. Some areas require standard lighting, while other units need specialty lights for diagnostic and treatment purposes.

(Surgical room with lighting setup)

PA and Communication Systems for Staff

Communication is the glue that holds any medical facility together. Over the years, PA and communications systems in hospitals have been helpful in communication. Communications interfaces use cables to pass information from one person to the next from a database.

(Ceiling loudspeaker)

Monitoring/Information Systems

Sensitive information is available in healthcare facilities. The information systems allow for the assembly, processing, and storage of data. It makes monitoring and evaluation effortless as all the data is available when needed.

(Monitor systems showing CT and MRI scans)

Electro-therapy Devices

Hospitals are currently using electro-therapy devices for specific ailments that do not have any other form of treatment. Electro-therapy devices require cables to function and deliver the treatment or aid in diagnostics.

(Electrostimulation device)

Endoscopy

Endoscopy utilizes a cable that goes inside the body to observe organ or tissue detail.

(Endoscopy procedure)

Electro-mobility

Mobility is an issue for patients, especially when in critical condition. Several electro-mobility options are available to help medics move patients around painlessly. Cables are intricate in the construction of the devices in this category as well as functionality.

(Electric wheelchair)

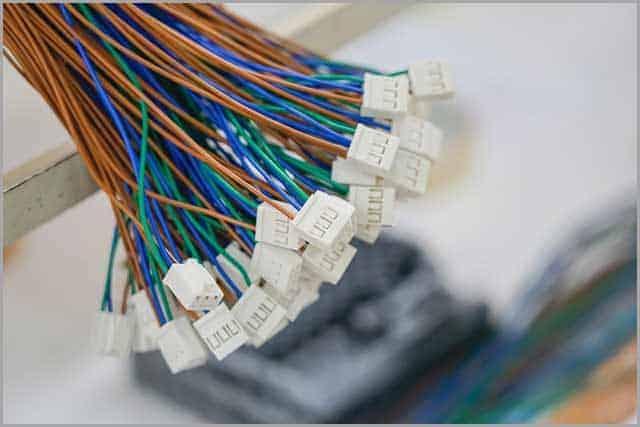

Major Categories of Medical Cable Assemblies

(Colorful Wire set for assembling electrical appliances)

Medical cables have different types of assemblies and connectors. There are three major assemblies. They are equipment and sub-assembly interfaces, communication, and patient interfaces.

All these are critical in the day-to-day functions of any healthcare facility. Get to know more about them below:

Medical cable assemblies vary based on the usage of the same. Below we explore the three major categories.

Equipment and Sub-assembly Interfaces

This assembly involves the installation of original equipment in the different parts of the facility. Equipment and sub-assembly interfaces are spread across the numerous medical departments, each serving a specific purpose. Retrofits and updates are the only reasons affecting the change in any assembly of this kind. Nuclear imaging devices such as gamma cameras are among those with this assembly interface.

Communications Interfaces

Communication is an essential component of any healthcare system, and an interface is indispensable in such environments. A lot goes into building an effective communication interface, and fiber optics, serial cables, and LAN are popular options within the medical field.

Patient Interfaces

This assembly contains a strong network of cables catering to specific patient diagnosis and treatment tasks. These three are the standard options that must facilities have.

Long-life Patient Interfaces

Hardwearing and flexible cables make long-life patient interfaces. Ultrasound imaging equipment is among the many sets with this type of interface. Most machines within any facility fall in this category as they need to be durable to assure longevity.

Limited-use Interfaces

Exposure to chemicals and mechanical stress are among the factors that cause wear and tear to medical equipment. This interface contains units built to last for a specific duration, and CCU and ICU monitor cables are some of those that need regular replacements and repairs.

Use-only Interfaces

Cleaning and sterilization of medical equipment are possible but not for use-only interfaces. They include catheters, fetal monitoring cables, and electrosurgical devices, among others.

Medical Cable Connectors

Connectors are vital when working with cables. Many variations are available, including;

Registered Jack (RJ) 45 Connectors

Registered Jack is a physical network interface for telecommunication and data equipment connections. RJ45 is an Ethernet jack that connects computers in a facility with an internet network. Computer applications and high-speed modems in health institutions work better with the RJ 45 connectors. Using these connectors guarantees fast and reliable services.

(RJ45 plug)

Bayonet Neill-Concelman (BNC) Connectors

Connectors in this family are miniature radio frequency connectors that are easy to connect or disconnect. These connectors’ first usage was in the military. BNC connectors work with coaxial cables to avail signal connections. A signal connection is necessary for the smooth operation of the equipment. Test equipment in an institution relies on this type of medical connectors to perform optimally.

(BNC connector)

DIN Connectors

The different types of DIN connectors available in the market have pins designed circularly. Without these connectors, PC keyboards, midi instruments, and an assortment of specialized medical equipment will be worthless.

(DIN connector)

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Medical Standards

Every industry has regulatory agencies that oversee the operations. These agencies set their requirements that manufacturing companies must abide by..

ISO Standards

The International Organization for Standardization is an agency that develops and publishes standards. Such standards cut across the economy’s different sectors, and the medical field is among the sectors they control. As such, it sets requirements that manufacturers must meet when producing medical cables. There have been no updates to the medical standards from this organization since 2016, and safety and specifications requirements are the top concerns of the 2016 updates.

IEC Standards

Most cables in the medical field are electrical; hence, IEC standards are crucial. The International Electrotechnical Commission (IEC) has an input on the standards set for medical cables. The regulations they form focus on the fundamental safety standards of medical lines and other equipment in this field. Thus, they have a model that guides manufacturers in the production process. The model guarantees the cables’ optimal usability and other devices. The amendment of the 3rd edition is currently underway. The last update to the laws was in 2018.

MDSAP Certificates

Medical equipment and cables have to go through different inspections to meet the other jurisdictions’ regulations. Medical Device Single Audit Program (MDSAP) provides medical device manufacturers with a single audit. It also acquires the necessary certification permissible in different countries. The guidelines that this program uses are developed by stakeholders in this business, making it comprehensive and legitimate. MDSAP offers an invaluable certificate suitable for use in many countries but not easy to get. There are no updates to the guidelines so far.

Key Requirements for Medical Cord Manufacturing

A company must have all the credentials and facilities necessary for setting up a medical cord manufacturing company. Here are some of the fundamental requirements that a company must have to make medical cables:

A Deep Repertoire of Application Knowledge

It is working with companies that understand the medical cables’ ins and outs inherent for better results. A company’s experience determines whether it can manufacture medical wires for different applications.

Material Expertise

The material manufacturers should use different types of medical cables to be suitable for the hospital setting. Durability, reliability, and flexibility are the top concerns regarding this aspect that manufacturing companies must guarantee. Experience in the medical equipment and cables field is necessary for every company, and such experiences ensure that their materials are top-tier and appropriate for the specific role.

A Deep Understanding of Manufacturing Principles

Control agencies in medical cable manufacturing set the principles that companies in this industry must follow. Companies operating with all the necessary certifications ought to be on the top of the list.

Cable Bundle Optimization

Getting medical cables with optimal performance is something that healthcare management teams want. Working with a company that offers cable bundle optimization makes work easier for everyone involved. It is best to avoid companies that do not provide such products and services.

In-house Testing

Medical cables and equipment need testing to ascertain if they perform well. In-house testing is a feature of medical cable manufacturers that you cannot overlook. The companies producing cables for medical use should have in-testing facilities, which confirms their quality and functionality.

Expertise in Hybrid Cable Assemblies

The medical industry is evolving with each wake introducing new technologies and, by extension, hybrid cable assemblies. Manufacturing companies with this expertise help make the installation process a breeze. It is one of the critical requirements in recent times as cable assemblies that do not produce hybrid solutions have limited options.

Critical Attributes of Medical Cable Assemblies in Healthcare Devices

Before buying any medical cable assembly, there are certain factors to consider. They include:

Durability

Medical cable assemblies’ usage is around the clock. Hence, the material and construction must be top-tier to ensure cables last long.

Reusability

Cables come in different types, with features permitting multiple or single-use. Reusable wires are the best option as they help cut down the cost.

Adaptability

The best cable assemblies should adapt to changing conditions and serve multiple uses. This factor also helps reduce the cost significantly and avails value for money.

Quality Components

Cables have distinct features and parts, each with unique components. All the elements a manufacturer includes in its brand should be of premium quality. With premium quality, the members prevent healthcare facility accidents.

Signal Integrity

Signals must go from one point to another for the normal functions to be achievable in the cable. Therefore, signal integrity is a factor worthy of attention.

Resistance against Chemical Exposure

Chemical exposure happens every minute in the medical field. The jacket shields the conductor and insulator from the chemicals, and the material covering the cable ought to be chemical-resistant.

Learn the Value of Today’s Medical Cable Manufacturers From 7 Facts of Industry

Value of Medical Cable Manufacturers for Medical Advancement

With each wake, manufacturers are improving medical cables for better value in the different applications. Smart devices are taking over other sectors. Within the medical industry, this means better devices to help in diagnostics and treatment.

Research and Development by Medical Cable Manufacturers

Medical facilities benefit from the research conducted by producers of equipment in this realm. Upgrades are necessary as the new kit comes into the market, and cables are among parts that evolve with time.

Growth in Custom Medical Cables Manufacturing

Bulky medical devices are slowly leaving the market for advanced options, which are small and efficient. Medical cables are also becoming smaller, with some devices going wireless.

Easy Installation and Implementation of Electric Wires

Complex setups are a thing of the past as medical cables advance into simple-to-use options with cable assemblies. Currently, manufacturers offer groups instead of single wires to make installation a breeze.

Quality Assurance by Medical Cable Manufacturers

Medical cable manufacturers must pay attention to every production stage, and it ensures high-quality standards. Additionally, they should have every client’s needs in mind, especially those who make custom orders, and what they order is what they should get.

Hassle-free Manufacturing of Custom Cable Solutions

Manufacturing companies streamline the production process to make it as seamless as possible. The prices they set for the different products they produce stems from the production process.

AI in Medical and Medical Cable Manufacturers

Medical cable manufacturers use all available resources to ensure that the products are top-notch and efficient. Robotics and AI are among the new trends in this industry, and Al facilitates the discovery of new medical techniques.

Benefits of Custom Medical Cable

Custom medical cables have numerous benefits that have seen many players in the industry join the trend. The top services of the custom medical line include;

Custom Configurations

Cables have different specifications best for specific tasks. The custom medical cable ensures that all the design needs are perfect for the job ahead.

Get the Right Custom Medical Cable

Resellers may not be privy to the intricate details of a particular cable. Getting custom medical cable is one way to avoid buying the wrong units.

Prevent Redesigns

Redesigns are many in the market, and buying this instead of the original variation has numerous consequences. Purchasing custom medical cables guarantee the originality of the product.

Reliability

Any device present in medical facilities must be reliable to prevent loss of life. Getting custom medical cables is the best way to make sure that the wires are secure.

Cable and medical devices must always be in pristine condition. Buying custom cables ensures that performance is optimum.

FAQ

How do Medical Cable Assemblies Work?

The procedure is subject to variability, and thus it is necessary to request this information from the company.

What is So Unique about Medical Cables?

Medical cables feature top-notch construction using premium quality materials, which sets them apart from the rest of the wires in the market.

What Do They Look like?

The appearances of medical cables vary for different applications, and there is no standard look for products in this category.

Are Medical Cable Assemblies Safe to Use?

Yes, medical assemblies are safe to use. Finding a reputable company to work with is the best way to guarantee the safety of the communities.

How Many Types Of Medical Cable Assemblies Are There?

There are three major types of medical cable assemblies: communication interface, patient interface, equipment, and sub-assembly.

What are Communication Interfaces?

Communication interfaces are infrastructure set up to facilitate conveying messages from one health facility area to the next.

What are Patient Interfaces?

Patient interfaces are durable structures whose installation helps in the diagnostics and treatment of patients.

What about Connectors?

Connectors play an intrinsic role in joining the electrical conductors to create a complete circuit.

How Can I Get the Most Flexible Cable?

Flexible cables have unique characteristics that you must be aware of to get the best.

How Can I Get The Best Medical Cable Assembly?

Working with experts in this field is the only way to get the best medical cable assembly.

How Can I Protect Medical Cables From Electromagnetic Interference?

Shielding is the easiest and most effective way to prevent electromagnetic interference. Conductive or magnetic materials will help you create a barrier that will reduce the effects of EMI.

How Much Does a Medical Cable Assembly Cable Cost?

Pricing is different for the different medical cable assemblies available today. Sophisticated setups cost more than simple ones, and they all have various applications.

How Can I Enhance The Life of Medical Cables?

Using medical cables the right way, proper cleaning and storage are ways to extend the lifespan.

Generic vs. Customized Medical Cable: What is the difference

Generic medical cables are those that are appropriate for specific applications. The lines are available in groups with particular features that make them ideal for a wide range of applications. Customized medical wires, on the other hand, are those made to handle precise applications. The medical lines are unique and best for a specific task, and the range of applications is minimal for customized variations.

Disposable vs. Reusable Medical Cable: What is the difference?

As the name suggests, disposable cables have a limitation when it comes to usage, and they are not ideal for decontamination, making subsequent use impossible. In contrast, reusable medical wires are suitable for multiple applications. After every use, the proper cleaning and decontamination procedures restore the usability of the line.

Conclusion

The market has a vast array of medical cables from different brands. Working with a reputable company is critical. Such companies ensure that the products they deliver meet the requirements necessary for clients. The medical cable provider should understand the applications of various products. Additionally, they should have products catering to the new machinery in the medicine world and other trends. Wiringo is among the companies in this industry with the best service delivery and top-notch products. We are happy to provide you with solutions at any time.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.