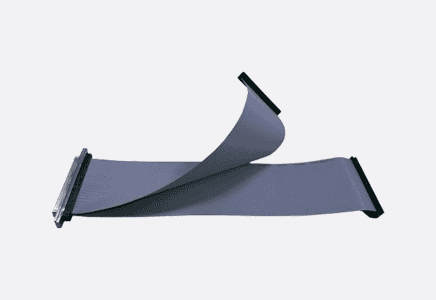

Molex Cable Assemblies

Wiringo specializes in Molex cable assemblies, offering moisture-resistant housings and high-density data transmission solutions tailored to your needs.

These precision-engineered assemblies outperform generic parts and support custom pin layouts, specialized materials, specific lengths, and harsh environments.

Our Clients

Molex Cable Assembly Services

Wiringo engineers Molex cable assemblies to fit your project. Here’s our custom process.

Consultation and Requirements Review

Our engineers collaborate with you to assess:

- The operating environment (extreme temperatures, moisture exposure)

- Performance requirements (data speed, current load, flexibility needs)

- Any industry-specific certifications needed (medical, automotive, military)

- Physical constraints (space limitations, bend radius requirements)

Design & Prototyping

We use CAD tools to create a 3D model of your assembly that accounts for:

- Connector selection: pin count, gender, locking type

- Wire specs: gauge, stranding, insulation material

- Shielding: braided, foil, or hybrid options

- Strain relief and overmolding needs

You'll receive a prototype for hands-on evaluation before full production.

Precision Assembly

Our certified technicians build each assembly using:

- Crimping and soldering techniques that exceed IPC standards

- Custom overmolding for environmental protection when needed

- Consistent quality checks at every stage of production

- Traceability for every component used

Rigorous Testing

Every product undergoes the following:

- Continuity testing: 100% verified for correct connections

- Hi-pot testing: ensures insulation integrity

- Mechanical testing: pull, flex, and torsion durability

- Environmental testing: thermal cycling and humidity resistance

- Signal integrity: validated for high-speed performance

Delivery & Ongoing Support

We provide:

- Comprehensive documentation: test reports, material certifications

- Custom packaging: reels, dividers, ESD protection

- Inventory management for repeat orders

- Engineering support for future design iterations

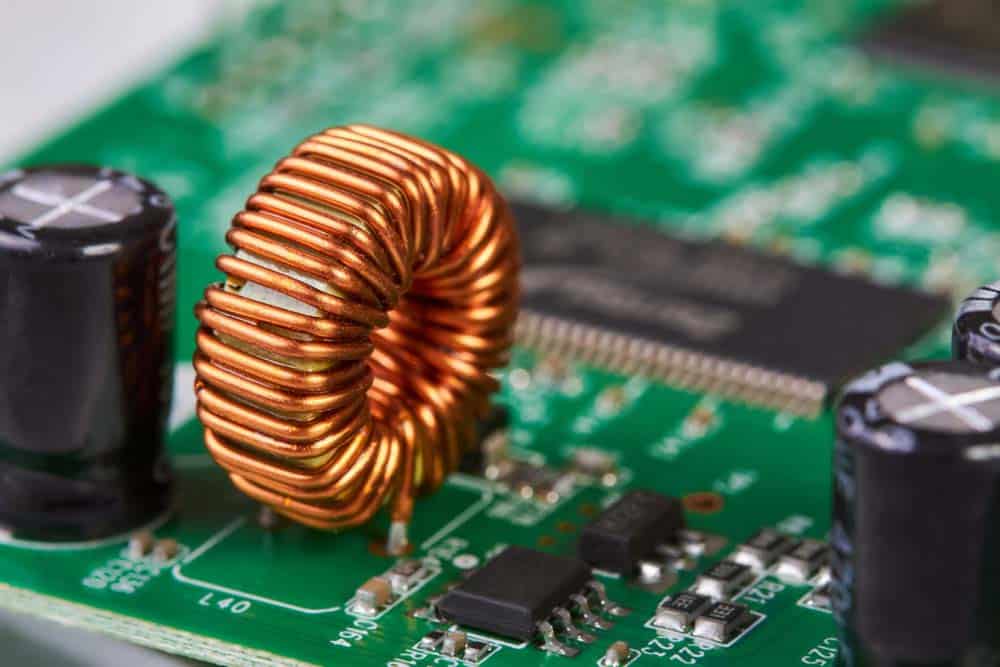

Products

We integrate Molex’s industry-leading connector technology into every custom cable solution.

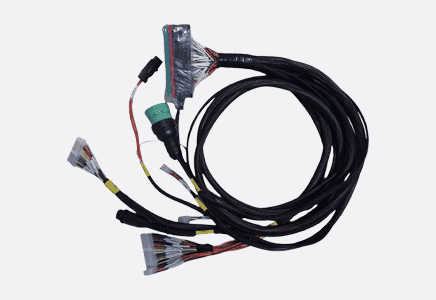

Heavy Duty Wire Harnesses

Handle up to 60A continuous current in compact form factors, ideal for EV charging and industrial power distribution.

Sealed Cable Assemblies

IP67-rated connectors with triple-sealed contacts for harsh environments like marine and agricultural equipment.

Discrete-Wire Cable Assemblies

Individually shielded wires maintain signal integrity in medical devices and aerospace instrumentation.

Overmolded Cable Assemblies

Molded strain relief and waterproofing for durable connections in robotics and outdoor applications.

Sealed Cable Assemblies

Custom-configured bundles with labeled wires for clean installations in vehicles and machinery.

Discrete-Wire Cable Assemblies

Ultra-thin pitch solutions for space-constrained electronics like wearables and drones.

Molex Connector Options

Wiringo selects the right connector based on your performance requirements and environmental conditions.

Mini-Fit Jr.™ Connectors

Deliver reliable high-current capacity (up to 13A per circuit) with secure TPA locking features, making them ideal for power distribution in industrial machinery and automotive systems where vibration resistance is critical.

Micro-Fit 3.0™ Connectors

Solve space challenges with their compact 3.0mm pitch while preventing misalignment through polarized designs - perfect for medical diagnostic equipment and robotic control systems requiring dense, foolproof connections.

Nano-Fit™ Connectors

Provide robust performance in a 2.50mm pitch configuration, enabling reliable connectivity in wearable health monitors and IoT sensors where every millimeter matters. They are ideal for ultra-miniature applications.

KK™ Series Connectors

Offer cost-effective wire-to-board solutions with standard 2.54mm spacing, commonly specified for appliance controls and consumer electronics where basic, reliable interconnects are needed.

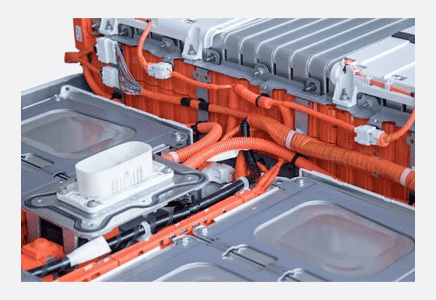

MX150™ Sealed Connectors

With IP67 ratings protect against moisture ingress and particulate contamination in agricultural equipment, marine systems, and electric vehicle components exposed to harsh conditions, especially when environmental sealing is paramount.

FCT D-sub Connectors

Provide durable, interference-resistant connectivity in factory automation controls and test equipment. Their rugged metal shell construction makes them ideal for legacy industrial systems.

SL™ Modular Connectors

Maintain signal integrity in high-speed data applications through advanced EMI shielding. They serve as the backbone of telecom infrastructure and data center interconnects, where noise reduction is essential.

Industry Applications

Some of the industries that use Molex cable assemblies include:

Automotive

Used in ADAS, EV charging, and sensors, and are built to withstand vibration, heat, and moisture.

Medical

Reliable connections for patient monitors and surgical tools designed for sterilization compatibility.

Consumer

Compact, high-speed solutions for wearables, smartphones, and smart home devices.

Why Choose Wiringo?

Wiringo is a trusted partner, delivering unmatched quality and performance tailored to your needs.

Customization Beyond Standard Options

From unique pin configurations to specialized shielding, we modify Molex connectors and cables to fit your exact specs, not just what’s in stock.

Precision Manufacturing

Our IPC-certified assembly process ensures every cable meets strict tolerances, with 100% testing for continuity, pull strength, and signal integrity.

Reliable Supply Chain

Strategic partnerships and suppliers ensure quality parts and on-time delivery, even during shortages.

End-to-End Support

Our engineers stay involved from design to post-delivery support to ensure your solution works as intended.

What Our Customers are Saying

Don’t just take our word for it; here’s what engineers and procurement specialists say about working with Wiringo:

I have received an shipment of the cables that was supplied (p/o : 5130903714 )

I would like to say thanks you , to you and your staff ( factory ) well done.

I am very happy with the quality of the work, ( C )

Thank you very much for your hot support and efforts for our parts supply.

We received your DC cables with thanks a lot.

All parts passed inspection successfully!

Lead Engineer

I just received the cables. Once again, we are very pleased with the results. We are also looking forward to further cooperation in the future.

Please take care.

I could not ask for anything better in terms of quality since everything arrived in perfect condition.

Thank you very much and I look forward to future projects with Wiringo.

Thanks again for Wiringo's hard work in making this project a success.

Frequently Asked Questions

What’s your minimum order quantity for custom Molex assemblies?

We accommodate prototypes (single units) to full production runs. Unlike many suppliers, we don’t enforce high MOQs, which makes us perfect for R&D or low-volume medical/automotive projects.

Can you modify existing Molex connector designs?

Yes. We alter pin configurations, add overmolding, or upgrade materials (e.g., high-temp insulation) while maintaining OEM compatibility.

Why is choosing the right Molex connectors important?

The Molex connector delivers power and signal integrity, prevents failures with secure locking and strain relief, resists environmental stress, and saves space with compact pitch designs.

Choose Wiringo’s Molex Cable Assemblies

Wiringo engineers select and customize Molex connectors to meet your application needs.