Are you tired of making the wrong choice of ribbon cables? Do you know the difference between a ribbon cable and a flexible flat cable?

It comes in various sizes and is necessary for different applications. Often, these cables appear quite confusing to individuals who find it difficult to spot their differences.

Not to worry, it is not as difficult as it seems. The information you crave is available at your disposal. Read on!

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Chapter 1: Understanding a Ribbon Cable

There is much discrete cable that you could use for a project and still get the desired out. However, one basic need for flat ribbon cable assembly is space. The use of flat ribbon cable assembly in the internal wiring of electronics devices conserves space. This cable assembly can transmit both power and data from point to point in the computer. It is necessary to stress that flat ribbon cable assembly is not limited to computing devices only.

What is a ribbon cable?

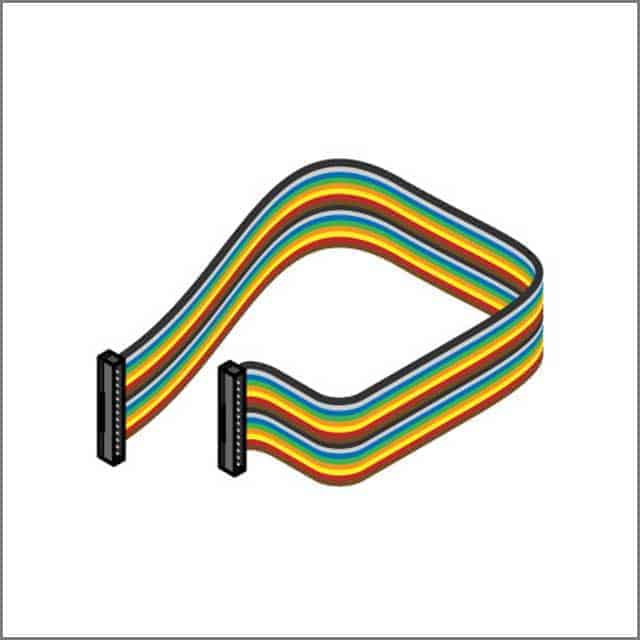

Another name for ribbon cable is multi-wire planar cable or hippie cable. It is a cable type with many conducting wires running parallel on the same flat plane.

The ribbon cable is flat and rectangular. The flexibility of the ribbon cable makes it easy to hold many connectors simultaneously and transmit a large amount of data through signals. Furthermore, ribbon cables help to manage conductors effectively, even where space is limited.

A typical instance that proves the usefulness of ribbon cable is its function in computer hardware. The ribbon cable connects the disk drive to the disk drive controller.

These cable types are specialized cables that connect IDE surfaces to IDE connectors.

Ribbon cable color coding

The essence of ribbon cable color coding is to prevent the occurrence of reverse connections. One rule for ribbon cable color coding is that the edge of the cable, which bears a red stripe, connects to pin 1 of the connector. The cable color-coding makes it easy to identify the different sets of connectors.

More importantly, it helps make the installation easier because it can easily identify the different conductors important to the connection.

Ribbon cable size

A pertinent question that engulfs individuals’ minds is the exact size of the ribbon cable that suits their needs. There are two ways of identifying ribbon cable sizes. The two factors considered are:

• The pitch or spacing of conductors

• The number of conductors or ways.

For the conductors’ pitch or spacing, a spacing of 0.05 inch (1.27 mm) is the most common form of ribbon cable spacing. This spacing type allows for a two-row connector with a pin spacing of 0.1 inches (2.54mm). Most personal computers favor this exact spacing ribbon cable size. It is a common type of ribbon cable size in floppy disk drive cables and custom parallel ATA cables.

Other types of ribbon cable connectors’ sizes are 4, 6, 8, 9, 10, 14, 15, 16, 18, 20, 24, 25, 26, 34, 37, 40, 50, 60, 64, and 80.

Ribbon cables are unarguably handy and play significant functions in printers and computers.

Benefits of the Ribbon Cables

Ribbon cables are flat and flexible, and these features afford them the ability to fit comfortably well in any compartment.

Also, the fact that ribbon cables are lightweight contributes very little to the device’s overall weight, and it explains why you see so many connectors in a computer but weigh less.

Another benefit is the reduction in overheating of devices. They can fold in a compartment and make more space, and these rooms are channels through which air can flow. Therefore, the device is less prone to failure due to overheating.

With a flat ribbon cable assembly, you can easily adjust the cables to suit the device’s connections. Also, it comes with its hand press for insulation piercings during adjustment. Rbbon cable assembly also comes color-coding to prevent reverse connection. In the absence of this, a reverse connection can damage the device.

Furthermore, the ribbon cable assembly is a good conductor. They possess good electrical qualities, and these qualities make them able to carry a larger current capacity.

Lastly, using ribbon cables eliminates the stress associated with troubleshooting bulk wires. They are organized already in a single piece.

IDC Ribbon Cable

Insulation-displacement contact (IDC) has another name to be Insulation-piercing contact (IPC). This process involves the forcefully inserting of a selectively sharpened blade or blades through the insulation. In this case, there is no need to strip the conductor bare before connection.

Application of Ribbon Cable

Ribbon cables are almost indispensable in manufacturing industries. They play a significant role in the consumer electronics manufacturing industry.

Additionally, ribbon cables are essential in building many electrical products. A good number of electrical products make use of ribbon cables. It is because of the miniature nature of ribbon cables, which makes them easy to use for designing electrical products.

Quite a several manufacturers rely on Flat flexible cable(FFC) to build laptops and mobile phones.

More so, ribbon cables are important for military-based equipment construction. They are also important in industrial environments.

These cables are necessary for the automotive industry. In constructing automobiles, manufacturers make use of ribbon cables.

Industries like aviation industries and space exploration find the ribbon cables essential in carrying out their activities.

Chapter 2: Ribbon Cable Types

Ribbon cables, like other cables, have different types. Hence, we shall consider the five types of ribbon cables, which include:

Rainbow Ribbon Cable

Rainbow ribbon cables are similar to the standard ribbon cables available. But this time, the wires have, by default, rainbow coloring. The rainbow coloring helps with easy identification and organization. Also, similar to the resistor color doing, where Brown can depict pin 1. It works as with the red stripe on one edge of a standard ribbon cable

Twisted Flat Ribbon Cable

The twisted flat ribbon cable is different from the standard ribbon cable. In contrast, they have two pairs of their conductor twisted and bonded. One benefit of twisted flat ribbon cables is that it reduces cross talk.

Standard Ribbon Cable

The standard ribbon cable comes with the ease of mass termination. A typical way to know one is by its color – They are grey.

Round to Flat Ribbon Cable

This unique type of ribbons cable combines mass termination ability with the ease of discrete wire cable. The conductors are folded into a circular frame and are split apart at the other end, and it allows them to ease access to use. Generally, this type of ribbon cable is suitable for areas with tight space.

Bonded Ribbon Cable

Bonded ribbon cables are organized and do not seem scattered about the place. However, it is also less flexible than other types, making its application difficult in tight spaces. One exciting advantage of this cable is that it provides straightforward mass termination with a range of cabling products. In addition, Bonded ribbon cables are of 3 types: Single Hook-Up wire, Coaxial cable, and Multi-Conductor cable.

Folded ribbon cable

Folded flat ribbon cable assemblies are the best when it comes to limited areas. Depending on the nature of a project, folded cable assemblies afford the needed flexibility for installation. You can fold them in the desired directions; however, you would require some arrangement tools for permanent folding.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Chapter 3: Ribbon Cable Connectors

There are quite a handful of ribbon cable connectors that are available with IDC termination. They are:

BT 224 connector

Another name for BT 224 connector is the IDC connector. Many standards define this connector type, such as BS 9525- F0023, DIN 41651, and MIL-C- 83505.

• BT 224 connectors mate with a purpose-made plug or two-row gird of header pins with 0.1 inches 2.44mm spacing.

• They are compatible with ATA cables.

D- Subminiature connector

These connectors are not as common as the crimp and solder bucket types.

• D- Subminiature connectors are suitable for serial ports and printer ports. It means that these connectors work perfectly for both printers and serial ports.

DIN 41612 connector

It is a connector type that is very common among different suppliers that operate together. Although the standard is now in an internationally standard form of IEC 60603-2 and EN 60603-2

• The DIN 41612 connector suits the Euro card bus, NU bus, Futurebus, VMEbus, Multibus 11, and Tram motherboards.

• All of the applications of DIN 41612 use a male Eurocard bus in a female DIN 41612 on a backplane.

PCB transition headers

PCB represents the Printed circuit board. It is a connector type with two rolls of pins with the same spacing as BT 224 connectors. For efficiency, these pins connect directly to the PCB.

This connector possesses high low contact resistance and long life. It also offers a cost-effective means of connecting PCB to other applications.

• It connects the wire to the board.

• It is also effective for separable header/sockets

• Suitable for dual-in-line application

Micro Ribbon connector

There are a host of names for the ribbon connectors. These names are a telco, 25 pair, miniature delta ribbon, mini D ribbon, MDR, Amphenol, or even miniature ribbon connector.

Microribbon connector possesses a shape similar to D- Subminiature connector with two parallel rows of contact. Its contacts are not pins. Rather, they are small bands of metal in the form of ribbons.

The female connectors of the micro ribbon connector possess a bail lock that connects them to the male counterpart for a secure connection.

• The micro ribbon connectors are a suitable fit for telecommunication equipment.

• It is also important for computers with a lot of contacts.

DIL Headers

The DIL headers possess pins with the same spacing as standard DIL ICs. They connect two Printed circuit Boards. Also, they work well with appropriate DIL sockets to form a plug and even socket pair.

• These connectors work well within replacing an IC in connection to an external device.

• It is also suitable as a PCB transition header on stripboards.

Chapter 4: Ribbon Cable vs FFC (Flexible Flat Cable)

Are there indeed differences between Ribbon Cable and FFC? Yes!

What are flexible flat cables?

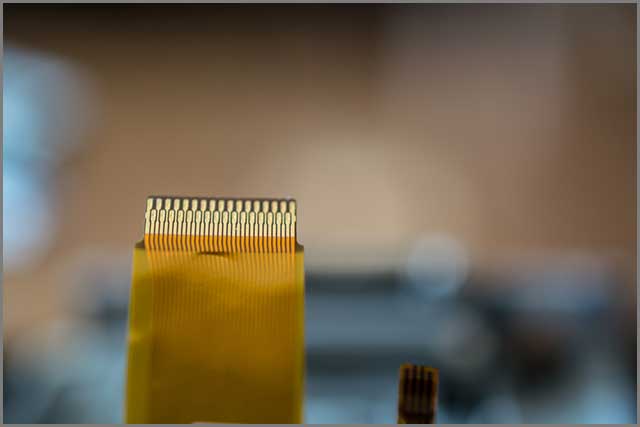

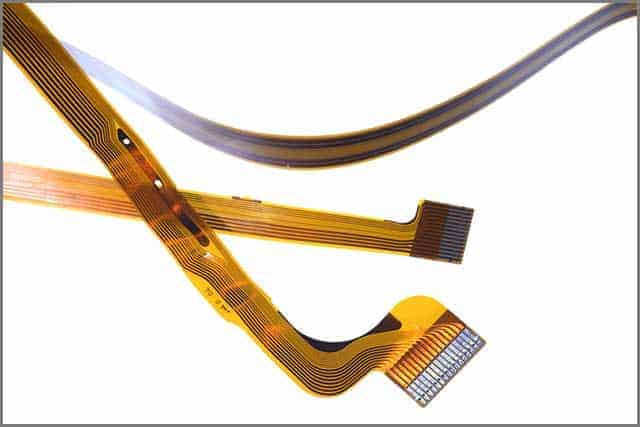

Flexible flat cables are a type of ribbon cable that is flat and flexible. These are direct connections without any additional components. It is a thin flat cable commonly found in high-density electronics applications. Its material is very flexible.

These cables possess a special sort of makeup. Its makeup is a flat and flexible plastic film base and multiple conductors on a surface.

FFC (Flexible Flat Cable) vs FPC(Flexible Printed Circuit)

Flat flexible cables (FFC), as we have discussed, are ribbon cables used mostly in high-density devices like computers. Their flat and flexible nature allows them to connect two components freely in a limited space.

However, FPC stands for Flexible Printed Circuit. Like FFC, it is flexible, having a conductive circuit sandwiched in between elastic polymers. Technically, FPC is more than just a cable; and it is more of a flexible printed circuit board. However, it is thinner, lighter, and less rigid compared to the traditional PCBs.

FFC Application

Flexible flat cables are important for easy cable management in high-flex environments.

It is a suitable cable for printers, scanners, copiers, fax machines, DVD stereos, LCD appliances, and other electrical products.

It is common in modern equipment to assist the printer connection between the head and the motherboard.

The FFC plays a considerable role in signal transmission and plate board connections.

FFC Specification

Pitch: Examples of pitches are 1.00 mm, 1.25 mm, 1.27 mm, and more.

Types: FFCs are Type 1/Type A and Type 2, or Type D. The difference here is that type A cables have contacts on one side and at both ends, and in contrast, Type D has connections on both sides and at both ends of the line.

Conductors Size: You can determine the size by measuring its width and thickness

Exposure Length: FFC cables gave their exposure length, and you can check for it at the end of the cable.

Stiffener: An extra layer of material at the opposite side of the cable’s exposed length helps ZIF or LIF connections.

Benefits of Flexible Flat Cable

The wires of a flexible flat cable are not wound like a round cable. They are lighter and more flexible. It makes it easy to protect the individual wires.

They do not occupy too many spaces like round cables

It offers a more sophisticated EMI/ RFI suspension. As such, it eliminates wire coupling issues.

The ends of flexible flat cables are thick.

Ribbon cable VS FFC: Difference

Both cable types are important in diverse ways. While one assist in a particular field, the other remains relevant in a field that suits it. However, flat cables existed long before the ribbon cables came into existence.

Ribbon cables are efficient in various areas like computing, aerospace, military, and robotics. These cables possess good superior quality, flexibility, and packaging efficiency and reduce the presence of electronic noise.

Despite these numerous advantages, the ribbon cables handle termination techniques rather poorly.

More so, there are also problematic cases of frictional heat in the cable during its repetitive motion cycles — also, conductors inside the cable move relative to one another.

The flexible flat cables don’t move within the jacket to retain their electrical properties and qualities. Another interesting feature of the flexible flat cable is that the cable’s conductors have similar physical and electrical lengths.

In flexible flat cables, the conductors are isolated to keep them stable. These cables are more flexible than ribbon cables.

FFC performs better than ribbon cables in heat, weight, volume efficiencies, and signal considerations.

Therefore, it is necessary to understand the capabilities of both the ribbon cable and flexible flat cables to ensure proper usage. In all, flexible flat cables possess better features than ribbon cables.

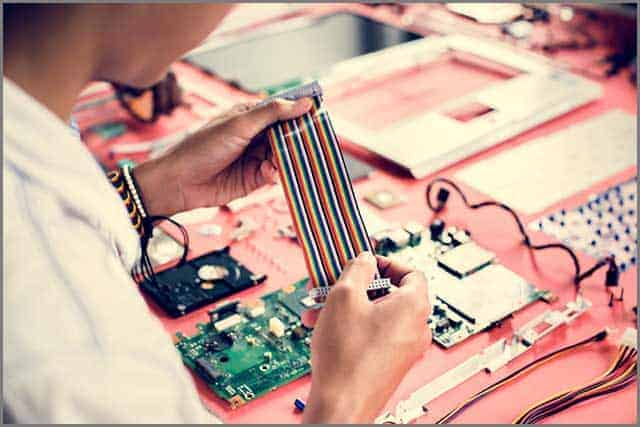

An image of a technician holding the flexible flat cable in a workshop

Chapter 5: How to Choose Ribbon Cable

Asides from recognizing ribbon cables, the confusion lies in choosing them. In choosing ribbon cables, there are quite a several factors to put into consideration. These cables are:

Pitch

Pitch is spacing. It refers to the spacing of conductors within the ribbon cable. The pitch depends on the cable requirements and specifications. Some examples of pitches include 0.5mm, 1mm, 1.25mm, and 2mm.

Ribbon cable pitch VS connector pitch

The ribbon cable pitch of the connector and that of a ribbon cable is never the same. The ribbon cable is always half of the connector pitch.

By this implication, the ribbon cable pitch is usually half of the connector’s pitch when there is a two-row connector pitch.

Another way of determining the pitch of the ribbon cable is by measuring the outside edge of the cable and then dividing the figure by the total number of connectors.

Extreme temperatures

Ribbon cables tolerate all sorts of temperatures, be they harsh or friendly. But, if ribbon cables operate perfectly in unfavorable temperatures, a silicon jacket is the best bet.

Flexibility

In choosing ribbon cables, flexibility is a necessary factor. Since ribbon cables are flexible, there is still a need to purchase a more flexible type. If the design is limited or requires a more flexible type, purchase a custom ribbon cable with greater flexibility that suits the job.

Long life

Consider the life span of the ribbon cable you intend to purchase. Like every other electrical component, choosing a ribbon cable that can survive the test of time is necessary.

Choose a ribbon cable that is adequately proven by professionals and assured of a long life cycle.

Fire resistant

Fire resistance is another factor to consider when choosing a ribbon cable. The importance is not only for the benefits of the electrical equipment but also for safety.

Make it a duty to settle for a ribbon cable type in line with the EU’s Restriction of Hazardous Substances Directives and fit according to fire safety standards.

Chapter 6: Custom Ribbon Cable Service at Wiringo

Wiringo is not just a body of professional teams specialized in different areas of expertise. With us, you are guaranteed a superb custom ribbon cable service, as it is a part of what we are known to do well; we are a team of seasoned professionals who take a keen interest in delivering effective results.

Shielded Ribbon Cable Assemblies:

As we stated earlier, shielded ribbon cables are the best fit for tight spaces. More so, they have numerous applications in computers and computer peripherals. Floppy drivers, hard drives, and CD drives use shield ribbon cables. Also, printers and some computer devices are not left out here.

However, there are limitations to shielded ribbon cables. Because they have fire and stab resistance, the cooling rate is also meager.

There have been adjustments to shielded ribbon cables in recent times, and these advancements now make them safer to use and much more feasible.

Shielded ribbon cables consist of an outer shield made out of copper braids. Also, some ribbon cables are double-shield. Aside from the external protection, they have an inner foil that bridges contact between the wires and the outer shield.

PCIe Ribbon Cable Assemblies

A PCIe ribbon cable is a cable type with many flat wires put parallel and side-by-side. Hence, they look more like a ribbon cable. PCIe ribbon cables help transfer data at a fast rate. We can see more of its use in computer systems and mobile devices.

A PCIe ribbon cable

Color coding is essential in PCIe ribbon cables. So, users can avoid any unpleasant cases. Color coding helps in pin identification and prevents reverse connection. In line with this, one edge of the ribbon cable has a red color to tell pin 1.

Determining the size of a PCIe ribbon cable is similar to that of ribbon cables, and we can classify them into two, namely Pitch and Number of conductors.

The pitch is simply the spacing between two conductors in the ribbon cable. Some of the commonly used spacing is 0.05inches and 0.1 inches. The wires of t

Conclusion

Ribbon cables are indeed important for various connections of sorts. They play important roles in connecting various applications like mobile phones, laptops, and electronic devices.

These colored-looking cables are very efficient in producing second-to-none output results. They appear in various sizes and pitches. It is important to derive all its information to fully use the ribbon cable.

Fortunately, the information you require is available in this write–up. If you want to know more about how ribbon cables work, reach out to us at Wiringo.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.