A shielded cable assembly can protect your wiring from EMI and RFI. From high-stakes military operations to cutting-edge medical technology, they ensure that electrical interference doesn’t compromise performance. But how do they work, and is it necessary to use them?

In this article, you’ll learn what shielded cable assemblies are, how and where to use one, and when and why a custom one may be better.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

What are Shielded Cable Assemblies?

A shielded cable assembly, which incorporates shielded cables and specific connectors, is designed to protect electrical signals from EMI and RFI.

How do Shielded Cable Assemblies Work?

Shielded cable assemblies work with the following functional parts:

- Shielding: First, it reflects a portion of the unwanted interference. Second, it redirects any remaining interference to a low-impedance path where it is safely grounded, preventing external noise from disrupting the signals the conductors carry inside the cable.

- Connectors: Made from cast zinc, aluminum, or metal-coated plastic backshells, most connectors support a complete 360° shield termination.

Note: Proper grounding is essential for shielding to function effectively. Grounding at both ends can create ground loops, introducing unwanted noise and negating shielding benefits. Instead, you should ground it at a single point, safely dissipating any interference.

Why is Cable Shielding Necessary?

While jacketing, insulation, and fillers are great for mechanical protection, such as waterproofing, abrasion resistance, and flexural strength, they don’t address interference issues. This is where shielded cable assemblies prove invaluable in noisy environments.

There are varying levels of noise between your electronic devices. When you choose your shielding types, ensure the most cost-effective and reliable solution. This allows you to enjoy uninterrupted operations.

| Noise Level | Noise Source | Typical Location |

| Low | Wiring found far from motors or power lines and near power or control relays. | Light assembly operations, offices, storage areas, and labs. |

| Medium | Wiring near control relays and medium-sized motors. | Average manufacturing plants. |

| High | Wiring near heavy motors, electrolytic processes, induction heating, generators, control wires and power lines, transformers, and relay controls. | Heavy processing plants like foundries and steel mills. |

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

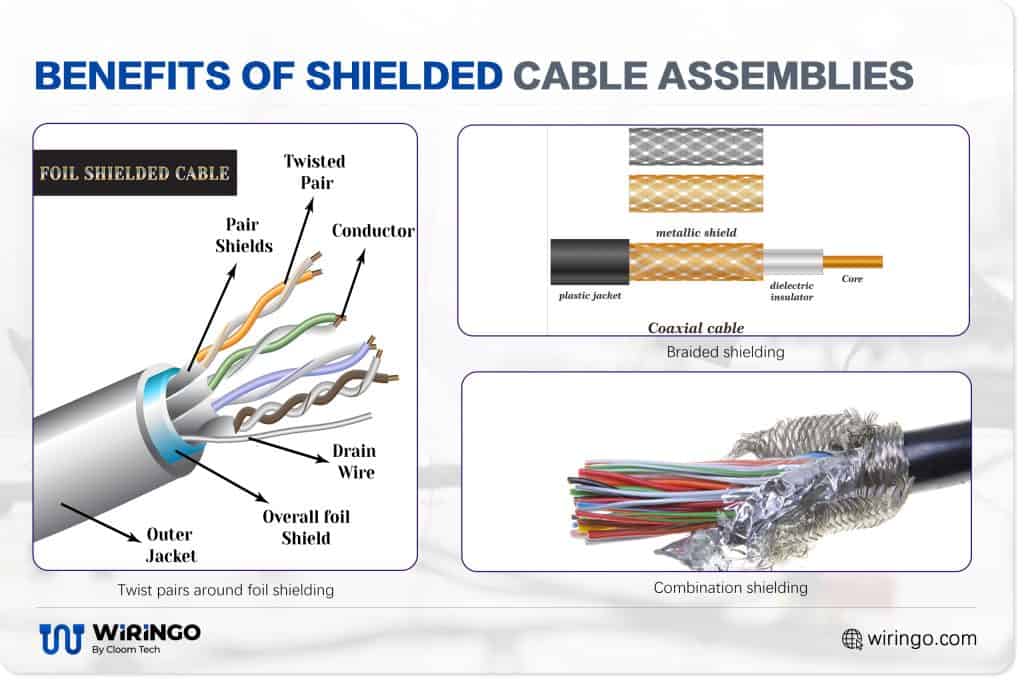

Types of Shielding in Cable Assemblies

With different types of shielding to choose from, you can enjoy shielding’s full range of features regardless of how much noise you are facing.

Foil Shielding

Foil shielding consists of a thin layer of aluminum or conductive material bonded to polyester or Mylar for enhanced resilience. It is often paired with a tinned copper drain wire, which helps eliminate interference and adequately ground the shield.

Pros:

- 100% coverage against high-frequency EMI

- Lightweight and easy to integrate into compact designs

- Lower cost compared to braided shielding

- Simple to terminate with a drain wire

- Compatible with other materials, allowing for customization

Cons:

- Less effective at low-frequency EMI blocking

- Poor mechanical strength and durability

- Limited flex life, making it less suitable for repeated bending

Best for:

- Telecommunications applications (data cables and coaxial cables) where high-frequency interference must be mitigated

Braided Shielding

Braided shielding is created by interweaving bare or tinned copper strands around the insulated center conductors in a crisscross pattern. The effectiveness depends on the number of strands, the weave’s tightness, and the braid’s angle.

Pros:

- Consistent coverage for signal protection

- Excellent mechanical strength and crush resistance

- Great flexibility and a long flex life

- A low-resistance path to ground

- Easy to terminate for secure connections

Cons:

- Only a 90% shielding coverage with limited effectiveness at high frequencies

- It is not ideal for tight spaces due to the bulkiness

- Less flexible compared to foil shielding

- Higher costs due to increased labor and material usage

Best for:

- Industrial applications (audio cables and power cables) requiring mechanical durability and low-frequency EMI protection

Spiral Shielding

Also known as served shielding, spiral shielding is similar to braided shielding. But it consists of single strands of copper wire wrapped in a spiral pattern around the conductor instead of being woven.

Pros:

- Extremely flexible, ideal for applications requiring movement

- Lightweight and easier to install in tight spaces

- Resistance to kinks and pulls

- Simple to terminate, reducing assembly time

- More cost-effective than braided shielding

Cons:

- Less effective against low-frequency EMI with a 90% – 95% shielding coverage

- Lower tensile strength, making it prone to damage over time

Best for:

- Flexible wiring applications (microphone cables and speaker cables) requiring movement and minimal interference protection

Combination Shielding

In applications that require superior shielding, manufacturers often combine multiple methods to enhance performance.

Pros:

- Maximizes EMI and RFI protection across a broad frequency range

- Balances shielding effectiveness, strength, and flexibility

- Can be customized based on environmental demands

- Reduces crosstalk when applied to individual pairs in multi-conductor cables

Cons:

- More expensive than single shielding types

- Can add bulk and weight to the cable assembly

Best for:

- High-performance applications in aerospace, medical devices, and industrial automation requiring superior EMI protection

| Foil | Spiral | Braid | |

| Single-End AWG Range | N/A | 36 – 52 AWG | 30 – 46 AWG |

| Core Size | 0.25” + | 0.004” – 0.450” | 0.012” + |

| Typical Coverage | 100% | 90% – 95% | 90% |

| Flex Life – Continuous Flexing | Poor | Poor | Good |

| Flexibility | Poor | Very Good | Good |

| Ease of Termination | Difficult: Often, you’ll need a drain wire. | No interweaving; therefore, it’s easier to terminate using multiple strands twisted together or individual shield wires. | Separating and terminating braided wire is difficult, and you’ll often need a drain wire. |

| Normal Frequency Range | High frequencies (over 100MHz) | Low frequencies (up to 1 MHz) | Low-mid frequencies (up to 100 MHz) |

Benefits of Shielded Cable Assemblies

- EMI and RFI Protection: Shielding prevents external noise from disrupting signals, ensuring consistent and accurate communication.

- Durability and Longevity: Shielding provides an extra layer of defense, reducing wear and tear.

- Cost-effective Solution: Shielding extends the cables’ lifespan and minimizes maintenance costs and downtime.

Common Industry Applications

From high-stakes military operations to cutting-edge medical technology, shielded cable assemblies ensure that electrical interference doesn’t compromise performance.

Military and Aerospace

Aircraft, satellites, and defense vehicles operate in high-noise environments. EMI can disrupt sensitive military communications, avionics, and radar systems. Shielded cable assemblies allow effective data transmission in combat, navigation, and surveillance applications.

Telecommunications

Shielded cable assemblies are crucial for maintaining stable connections in fiber-optic infrastructure, data centers, and broadband networks.

Medical

Medical devices depend on precise, interference-free operation. In applications like MRI and CT scans, even minor signal disruption can lead to inaccurate readings, affecting patient care. So, shielded cable assemblies are necessary for imaging equipment, patient monitoring systems, and diagnostic tools.

Industrial, Agricultural, and Renewable Energy

In industrial robotics manufacturing, renewable energy installations, such as solar farms and agricultural automation, shielded cable assemblies protect control systems from EMI generated by heavy machinery, motors, and electrical grids.

Automotive & EVs

Modern vehicles, especially electric vehicles (EVs), contain complex electronic systems that must operate without interference. Shielded cable assemblies are especially beneficial for advanced driver-assistance systems, battery management, and onboard communications.

Choosing the Right Shielded Cable Assembly

Selecting the right shielded cable assembly is essential for optimal application performance.

Key Factors to Consider

- Environmental Conditions: Shielded cables can be used in two scenarios. The first is when the cable is expected to run near potential sources of EMI. The second involves cases where corruption or degrading of the transmitted signals could lead to costly or damaging results. On the other hand, office spaces, different kinds of commercial premises, and other domestic environments usually don’t have substantial EMI sources. Therefore, the extra costs of having shielded cables would be unnecessary in such environments. A twisted pair of wiring will be enough to do the job.

- Signal Integrity Requirements: High-frequency or data-sensitive applications, such as medical devices and telecommunications, require superior shielding to prevent data loss or interference.

- Cable needed: Choose a cable suitable for the application. Cables that undergo frequent flexing typically require a spirally wrapped shield rather than a braid shield. A foil shield offers full coverage against high-frequency EMI, while a braided shield adds durability and protects against low-frequency interference.

- Connector options: The shielding effectiveness of the connector should match that of the cable. High-quality cables cannot compensate for poor connectors, and superior connectors cannot improve the performance of a poorly constructed cable.

Custom vs. Standard Assemblies

Custom designs allow for wide cable and connector options, ensuring compatibility with specific system requirements. On the other hand, standard cables are more cost-effective and readily available for general applications.

Choosing between them depends on whether the application demands precise performance optimization or a budget-friendly, off-the-shelf solution.

Shielded for Success – Get the Right Cable Assembly for Your Needs

Using shielded cable assemblies in complex or high-risk settings can be helpful for reliable signal transmission. However, custom ones provide a more efficient solution. With decades of experience in manufacturing, Wiringo has extensive expertise in optimizing cable assemblies for electromagnetic compatibility (EMC).

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.