With the wide variety of connectors available, it’s important to choose the one that aligns with the specific requirements of your application. Choosing the right wire harness connector is important for ensuring minimal signal loss, efficient power transmission, and the reliability of various systems. In addition, your choice ensures durability and compliance with industry standards.

The article below will explore the key types of wire harness connectors, their specific applications, and emerging trends in design and technology shaping the future of connectivity solutions.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

What is a Wire Harness Connector?

Wire harness connectors are devices designed to join electrical wires, cables, or circuits, ensuring stable and secure electrical connections within a wiring system.

Connectors play a vital role in maintaining the reliability and efficiency of electrical systems by facilitating seamless power transmission and signal flow while minimizing failures or interruptions. Connectors are supposed to ensure optimal performance and reliability across the whole system, whether for high-current capacity, signal integrity, or durability under harsh conditions.

Their design materials, features, and configurations enable the smooth functioning of complex electronic systems ranging from consumer electronics to industrial machinery and automotive wiring.

The component of wire harness connectors

Wire harness connectors have two core components.

- Housing: This component houses the terminals and provides an insulating case that protects the terminals from bridging and corrosion and ensures stability. They are primarily insulators.

- Terminals: These components are responsible for signal transfer. Technically, they are the pins you see in a connector, and their makeup is of metals with high electrical properties for conduction.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Types of Wire Harness Connectors

Wire harness connectors are available in various types and sizes, each designed to meet specific application needs based on environmental, electrical, and mechanical requirements.

Plug-and-Socket Connectors

Plug-and-socket connectors consist of a male plug and a corresponding female socket, ensuring a secure yet easily detachable connection.

Their adaptability and ease of use make them popular across various industries, especially in consumer electronics, where devices often involve modular components that need convenient disconnection.

Terminal Blocks

Terminal blocks are modular connectors that provide an efficient and organized way to join wires in an electrical system.

These connectors are commonly used in HVAC systems to manage connections between control units, sensors, and power supplies or industrial control panels to improve system organization, simplify troubleshooting, and ensure safety in complex wiring setups.

Binding Post Connectors

These connectors are like screws that terminate a conductor. Also, they function to clamp wires to posts temporally. You can see their applications in some audio gadgets like amplifiers and loudspeakers.

PCB Connectors

PCB (Printed Circuit Board) connectors are essential components that allow efficient signal transmission and power distribution within compact electronic systems, offering an excellent space-saving solution for modern, high-density designs.

PCB connectors come in several categories, including:

- Board-to-Board Connectors – directly connect two PCBs to enable signal transfer without additional wiring.

- Wire-to-Board Connectors – link external wires to a PCB to facilitate connections with other components in the system.

Examples of applications include consumer electronics like smartphones and laptops, where compact designs are important.

Rack and Panel Connectors

Unlike other connectors, the Rack and Panel connectors are adjustable and suitable for stationary devices. They have types based on their connection. Examples include a cable to the panel, a rope to the line, and a rack to the board. Their application areas include telecommunications (e.g., server room connection), printers, and more.

Circular Connectors

Circular connectors are designed to resist dust, moisture, and heat, making them ideal for harsh and outdoor environments.

Their rugged construction ensures reliable performance even in challenging conditions, providing long-lasting connections in systems where environmental resilience is vital. Examples include portable power tools and machinery used in agriculture or construction.

Blade Connectors

Blade connectors are like plug-and-socket connectors, with flat conductive blades connecting wires to a receptacle. Applications include automobiles and some electronic devices.

Ring and Spade

Ring and Spade could be small in size but help ensure a firm connection. They are put in a post and screwed together to ensure harmony. They come insulated or exposed, depending on the one you need for your project. Furthermore, you attach the conductor to the connector by crimping or soldering it together.

Most often, ring and spade connectors are helpful for ground or earth connections. The connection here is also seamless and applicable to areas with a point-to-point link.

Selection Factors for Wiring Harness Manufacturers

When choosing wire harness connectors, manufacturers carefully consider several key factors to ensure optimal performance and compatibility with their systems.

Technical requirements of your wiring harness

When choosing connectors, it’s important to prioritize electrical, safety, mechanical, and environmental parameters. Key considerations include:

- Wire Gauge Compatibility – connectors must match the specific wire sizes they are designed for. Using the wrong wire gauge could result in loose or unreliable connections.

- Voltage and Current Ratings – choosing a connector with ratings that exceed the system’s requirements ensures optimal performance and minimizes risks of failure or overheating.

- Circuit Density and Size – keep in mind the number of contact pairs you need and ensure the connector size and total separating force align with the demands of the circuit.

- Data Transmission Speed – choose connectors that support high-speed signal transmission without degradation or interference.

- Size and Weight – the connector should fit within the design constraints of the product while remaining as lightweight as possible.

- Durability: evaluate environmental factors such as moisture, temperature fluctuations, and vibration. Ensure the connectors meet IP67 or IP68 protection standards for environments requiring waterproofing.

Demands for your wiring harness termination

Termination methods refer to the connection method of connecting the contact pairs of the connector with the wire or cable. Choosing the correct termination method and using the right termination technology are also essential aspects of using and selecting connectors.

- Twist-on connectors are commonly used in residential wiring for their simplicity and reliability.

- Crimp-on connectors are often used in industrial and automotive applications due to their firm, vibration-resistant connections.

- Push-in connectors use a spring mechanism to secure wires, making them ideal for quick and straightforward installations.

Balancing Cable Assembly Types and Quality

When building a wiring harness, you must choose receptacles and mating connectors to make the required connections.

- Point-to-Point Cable Bundles create a direct interconnect topology commonly used for straightforward, one-to-one wiring solutions.

- Bifurcated Cables – a more complex wiring harness setup that allows connectors and receptacles to be mixed and matched across multiple boards.

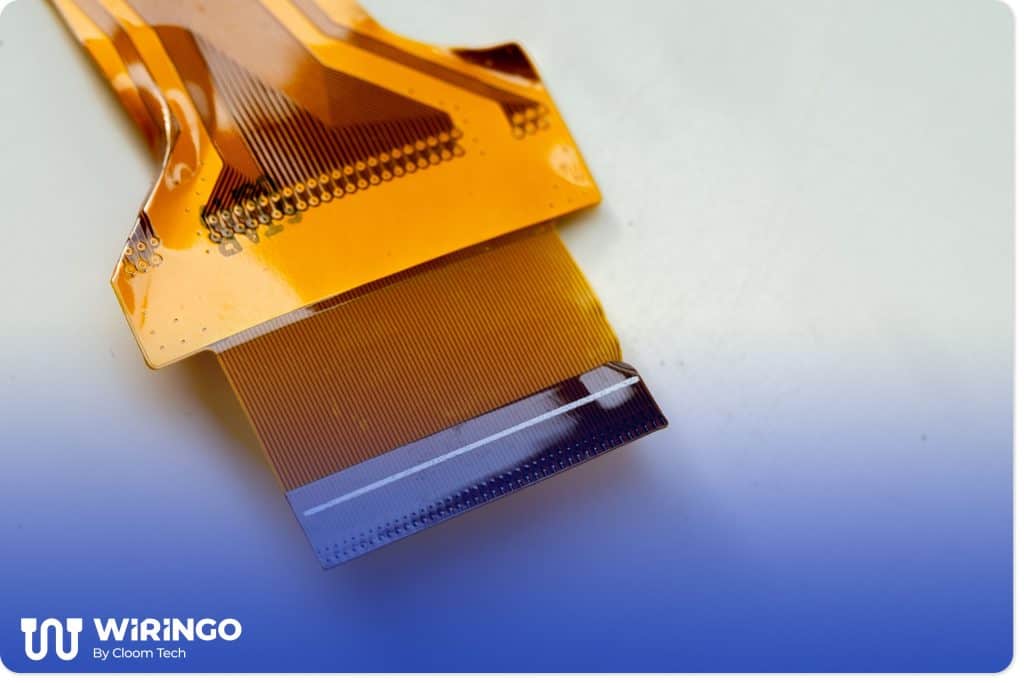

- Flex ribbons – facilitate using edge connectors, surface-mount connectors, and through-hole connectors to interface with multiple PCBs.

Industry-Specific Applications

Wire harness connectors are critical components across various industries, with specific types designed to meet specific requirements.

- Automotive – heat-resistant and weatherproof connectors ensure reliability in harsh environments, such as external lighting systems or engine compartments.

- Robotics – flexible and lightweight connectors accommodate compact designs and high-mobility systems.

- Industrial – durable connectors with quick assembly and maintenance features, like terminal blocks, facilitate efficient system updates and repairs.

- Aerospace – circular and crimp connectors designed for high vibration resistance and durability under extreme environmental conditions.

- Consumer Electronics – compact PCB connectors are used in devices like smartphones and gaming consoles to save space and enable high-speed data transfer.

- Healthcare Equipment – secure and sterile wire harness connectors are used in medical devices like diagnostic machines and surgical tools, that require reliability and minimal interference.

Trends Shaping Wire Harness Connector Design

Innovative trends in wire harness connector design are reshaping the industry to meet the demands of modern applications.

Miniaturization for Compact Systems

The trend toward miniaturization is driving the development of more miniature connectors that maintain high performance and reliability. Compact connectors are essential for electronics, medical devices, and other applications where space is limited, ensuring functionality without compromising durability or efficiency.

Sustainable Materials

Growing environmental awareness has increased the demand for connectors made from recyclable or biodegradable materials. These eco-friendly options reduce environmental impact and align with global sustainability initiatives, making them a preferred choice in industries prioritizing green solutions.

Smart Feature Integrations

Modern connectors are now incorporating advanced technologies, such as:

- Fiber-optic connectors – for high-speed and high-bandwidth data transmission.

- High-speed interfaces – that cater to the demands of fast and reliable communication.

- Smart connectors – with integrated sensors or IoT compatibility, enabling real-time monitoring, diagnostics, and predictive maintenance.

Common Wire Harness Connector Issues

If you don’t prepare for these errors at the design stage, you might waste resources after production.

Contacts

Contacts are tiny metals in a connector that carry electric current. The issue with contacts is that they can become corroded if not designed well. Hence, this can affect the current transfer.

Another issue with contacts is their mating cycle. Because connectors can often undergo a series of disconnections and reconnections, their grip is prone to become loose. Hence, while deciding on a connector, consider a high mating cycle, especially when your wire harness is in an area of frequent mating.

Crimping

The issues with crimping connectors to wire harnesses are more human or machine error. This error may lead to failure to crimp the connectors correctly. This can result in loose connection, moisture build-up, and eventually short-circuiting. For these reasons, you should use the right crimp tools and techniques to crimp connectors.

Strain Relief

Every professionally designed wire harness should have strain relief. It is a bit more than the actual length during design to accommodate wires’ movement in a bend. This strain relief will prevent high mechanical stress that may pull out the connectors from the wire harness.

Over-molding

Another error with the wire harness connector is over-molding. Overmolding goes a long way in determining how long it will last, depending on the over-molding material. The choice of materials for over-molding depends on the application’s environmental factors and mechanical demands.

Ensure Reliable Wire Harness Connections with Wiringo

Choosing the right wire harness connector is important to maintaining reliable, efficient system performance across various industries.

At Wiringo, we prioritize understanding your unique requirements to deliver products that combine optimal performance with long-term reliability. Our supply chain ensures exceptional value, providing solutions designed to meet the demands of your specific applications. Whether you require connectors capable of fitting into tight spaces, enduring specific environmental challenges, or handling higher voltages, our team of experts is ready to help.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.