A wire harness assembly combines electrical wires or cables wound together using components such as straps, conduits, or other methods. It supplies power to specific devices or systems. Having the wires wound together makes it easy to interpret the connection ends. However, labeling the wires can be favorable despite knowing the types. On that note, let’s dig into wire harness labeling and the importance of labeling the wires.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Wire Harness Labels Understanding

Wire and cables have become a considerable part of the contemporary world. The Wire and cable markings help identify correct connections and detect any dangers. They come in handy in construction sites, manufacturing sites, and office setups.

Electrical experts use cable and wire labels to ensure that those working on the job site know what they are doing and can streamline the systems to satisfaction and safety.

What a Wire Harness Assembly Label Can Tell You

A Labeled wire harness assembly helps share information in the following ways:

Barcodes: Various barcode configurations can relay information to individuals using a mass of wires. The configurations include Code 39, Code 128, GS1-128, Codabar, EAN-13 and EAN-8, QR Code, ITF-14, etc.

Text: You can print the label with the product’s information and then fix it to the correct wire or cable.

Certification code: When using a wire For UL-certified products, a mass of wire can have a CSA or UL tag.

Codes on labels

Why is wire marking important?

So, find out below why wire marking is essential.

- Color Coding of Wires is Not Enough

Using color codes to create a wire harness assembly can suffice. But you must remember that products and wires come from different companies and may have different colors. Integrating them may cause problems if you are not sure of the colors.

Therefore, it’s best if the wires, single or bundle, have labels in images, integers, or words, making it easier for anyone to figure out what goes where during installations.

- Makes Sure Safety

In any electrical setup, safety is critical. Wires and cables come in varieties and aim to smooth operations. However, professionals may suffer from electrical shock if the wires have no proper labeling. For example, a professional may make a mistake, cut a live wire due to poor tracing, and suffer an electrical shock.

Therefore, having a labeled system is ideal for preventing such cases and keeping everyone safe.

- Improves Reliability

There are situations when you have to change your wiring system. For example, you’ll unplug the cables to make it possible to change the system. Unplugging the wrong one will cause power failure hence a system breakdown.

You won’t face such troubles when the cables and wires have the correct labels. You can rely entirely on the cables to guide you through the process.

- Simplifies Troubleshooting

System failures are everyday happenings in any electrical setup. Therefore, you should conduct proper investigations to troubleshoot the problem. Professionals follow wires step by step, trying to determine the problem’s origin. This process can be easier if the cables and wires have proper labels.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.

Top 6 Types of Wire and Cable Labels

There are several wire marking labels that you can choose from. They include:

- Heat Shrink Labels

This label installation occurs during the system fabrication. Heat shrinks labels provide a long-lasting solution to wire labeling and are resistant to drastic conditions. The advantage is that you don’t have to terminate the wire using crimps since they slide over the cable with the slightest clearance.

- Self Laminating Wire Labels

Self-laminating labels apply to wires that are already terminated. They entail a white font label with a clear back tail. You can use a printer or your hands to mark the white part. When fixing the label on the wire, the white part wraps around the wire, and the clear part wraps around the white part.

The transparent part acts as a ‘‘self-laminating” part of the constituents of the label.

- Wire/Cable Tags

They label any sized wire but are best for larger wires or tubes. These labels apply to unterminated wires. As much as they are durable, their drawback is that they slip against the wire.

- Wrap-around labels

These labels have symbols printed around them using a heat transfer or laser printer. You can arrange for pre-printing in advance.

- Cable flag labels

These are adhesive flag-shaped labels. They are less durable because the encasing material is thin at the base. They can take up multiple texts, which makes them compatible with barcodes.

- Hook-and-loop labels

Hook and loop labels do not need adhesive to attach and hang on the material. It has grips, allowing one to reapply it multiple times.

The Lable Printers that Make it all Happen

The modern world has given individuals options to choose from. Depending on your project’s requirements, you can get pre-printed labels or print your wire labels. Both options are ideal.

So let’s look at each option individually and see which is best. If you decide to get pre-printed markers, you’ll have the chance to do some window shopping and decide on the marker of your choice. You’ll place an order and wait for your delivery.

The only issue with pre-printed markers is that they may be of low quality, and the waiting period for delivery can be frustrating.

Now, let’s look at the print-your-own markers. Currently, the market has desktop and portable printers, which you can use to design your labels as per your desired look and print in the comfort of your location.

For large volumes, the desktop printer is best for use.

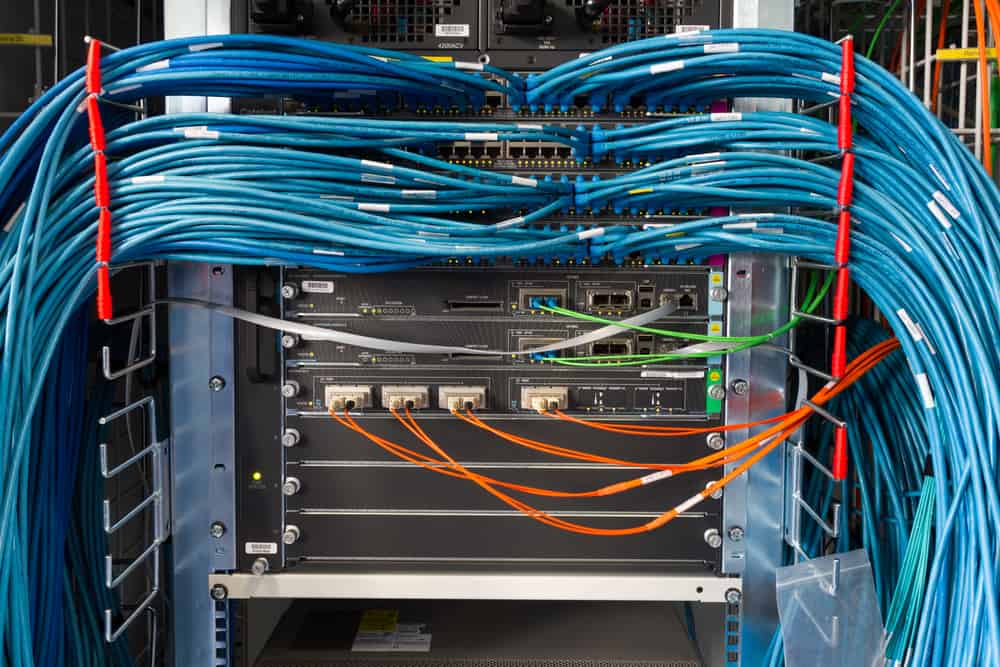

Cable management

5 considerations when selecting a wire marker

Before you choose a wire marker, here are a few questions you should ask yourself:

- Is the wire marker durable?

No one wants a marker that will wear out in no time and undergo the struggle of another purchase. Therefore, choosing a durable material will save you the hassle and some coins. Also, before purchasing, check whether the marker is associated with water, chemical substances, or environmental factors.

- What are the marker material options?

Consider a material that can withstand harsh environmental challenges. The materials can be a polyolefin, vinyl, or nylon.

- What are the marker types?

Choose a marker depending on your necessity. Check whether you need a permanent or temporary marker, adhesive or non-adhesive, and the information you need to fit in the label.

- What is the size of the wire gauge?

You’ll need to know your wire’s thickness before getting a marker. You can use a wire gauge tool to measure the thickness of your wire.

- What’s the location of the marker?

Consider whether you’ll be marking the wire before or after termination. Self-laminating and wrap-around labels are suitable for use before or after wire termination. While heat shrink markers are suitable for use before wire termination.

Wire Identification Options at Wiringo

To achieve your harness assembly needs to match your specifications, Wiringo offers you the following options:

- Adding secret numbers

- Custom writing

- Adding special identity numbers,

- Adding a part or reference number,

- Wires origin point

- Adding bar and color code,

- Adding the company’s logo

Conclusion

Cable and wire labeling is essential in the identification and assembly of electrical connections. Professional experts can achieve any installation through proper wire harness labeling. The market has varieties of wire markers to choose from. At Wiringo, we equip you with all you need for properly and securely labeling your cables and wires.

Hommer Zhao

Hommer Zhao serves as Director of Wiringo, leveraging a wealth of expertise in custom wire harness and cable assembly.

Drawing on more than a decade of hands-on expertise in the electronics field, Hommer focuses on wire harness manufacturing, custom cable assembly, and expedited restricted product production. His operations include a pair of wire harness production facilities and two dedicated PCB manufacturing & PCBA sites, all strategically located across Shijiazhuang, Shenzhen, Jiangmen, and the Philippines.

Hommer frequently refers to resources like Wiring Harness News for up-to-date insights and methods related to wire harness production.

Beyond his research and reading, Hommer also contributes to the Wiring Harness Manufacturer’s Association (WHMA), which offers invaluable resources and professional guidelines to wire harness specialists.

Get Your Free Sample!

Explore our custom services now. Email us at [email protected] for more details.